Infinite-level sectional reconstruction sliding sleeve device triggered by machinery or hydraulic pressure

A technology of segmented reformation and infinite level, which is applied to the valve device of wellbore/well, production fluid, wellbore/well components, etc., which can solve the problem of increasing fracturing friction, limited number of segmented series, and increased risk. issues of sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

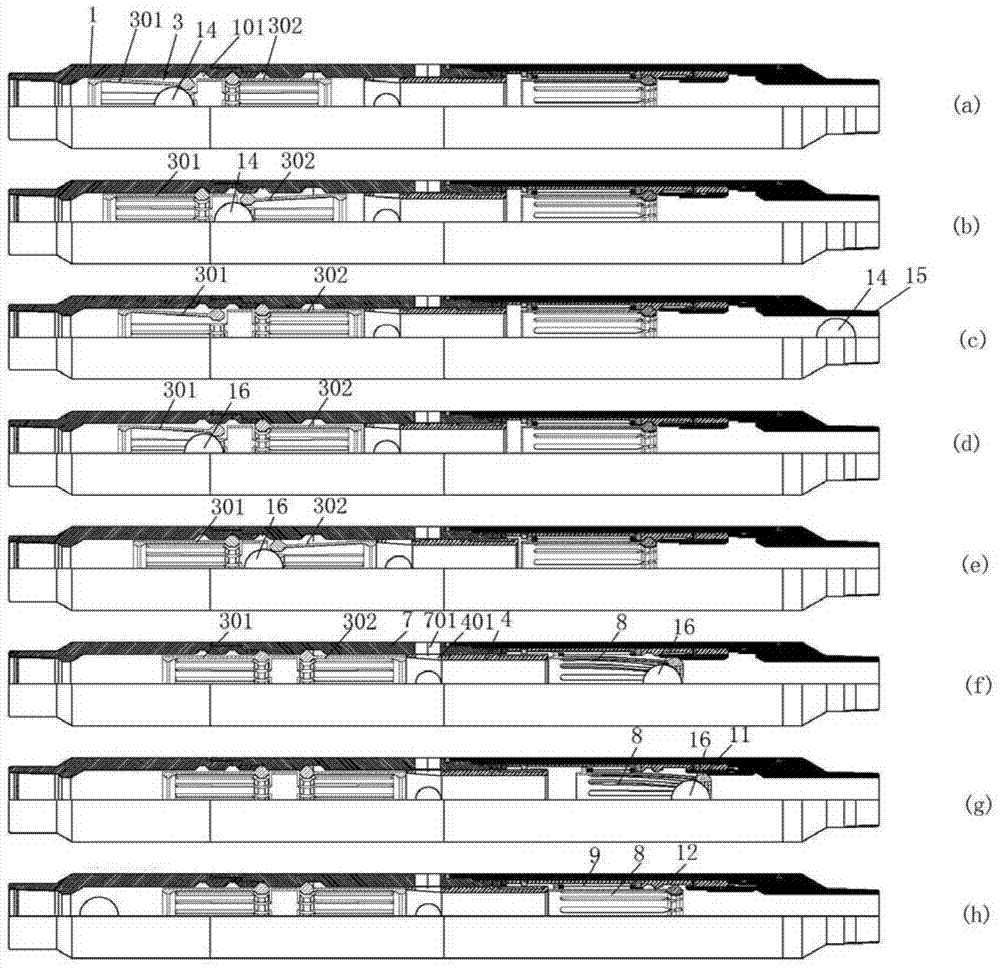

[0023] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

[0024] The core of the present invention is to transform the sliding sleeve device in the fracturing well, by setting a scalable elastic sleeve and a deformable variable-diameter ball seat and improving the surrounding parts of the elastic sleeve and the variable-diameter ball seat, thereby The use of low-density fracturing balls of the same size can open several stages of sliding sleeves and realize full bore, so that the number of fracturing stages can be increased infinitely, and the refined transformation of the reservoir can be realized.

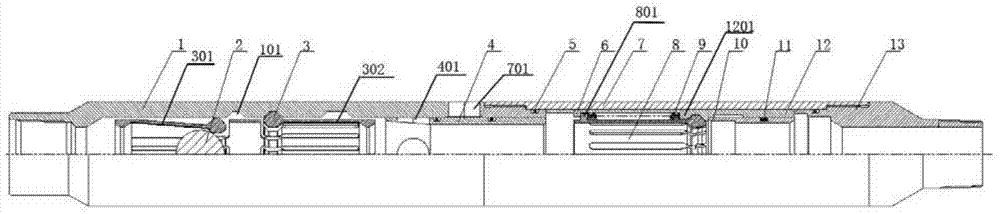

[0025] Specific examples see figure 1 ,like figure 1 As shown, a mechanical or hydraulically triggered infinitely staged segmented s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com