Automatic leveling device and leveling method of high-precision upright air-floating rotary platform

An air-floating turntable, high-precision technology, used in measuring devices, static/dynamic balance testing, balance weights, etc., can solve problems such as the disturbance torque index affecting the turntable, and achieve improved trimming accuracy, high-precision leveling, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

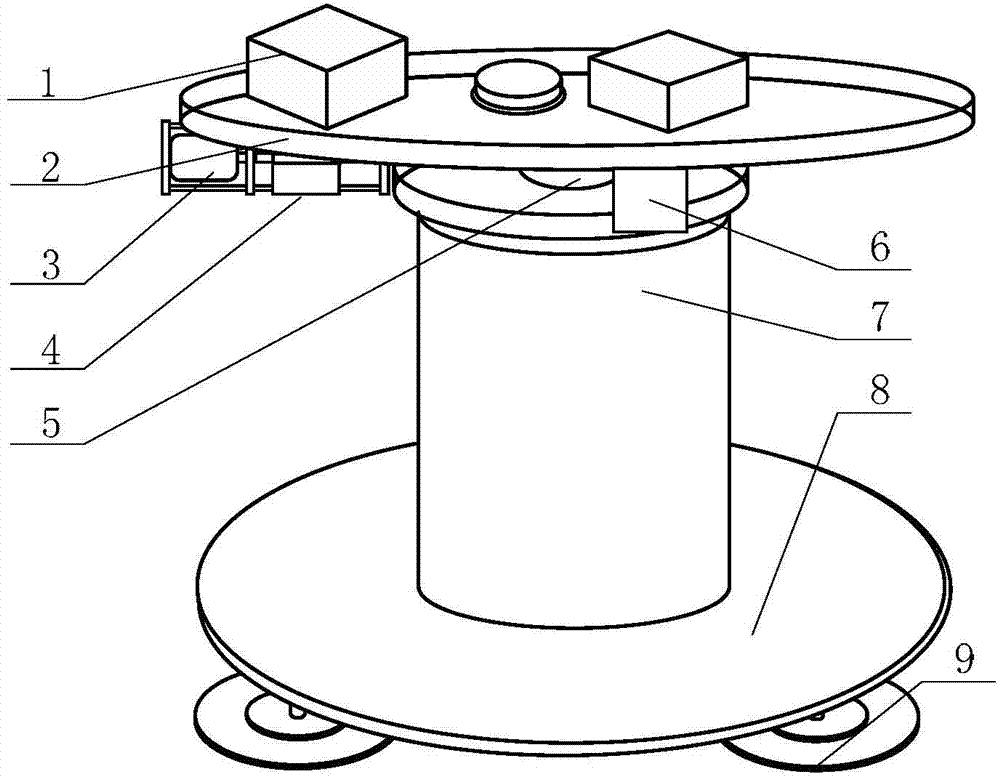

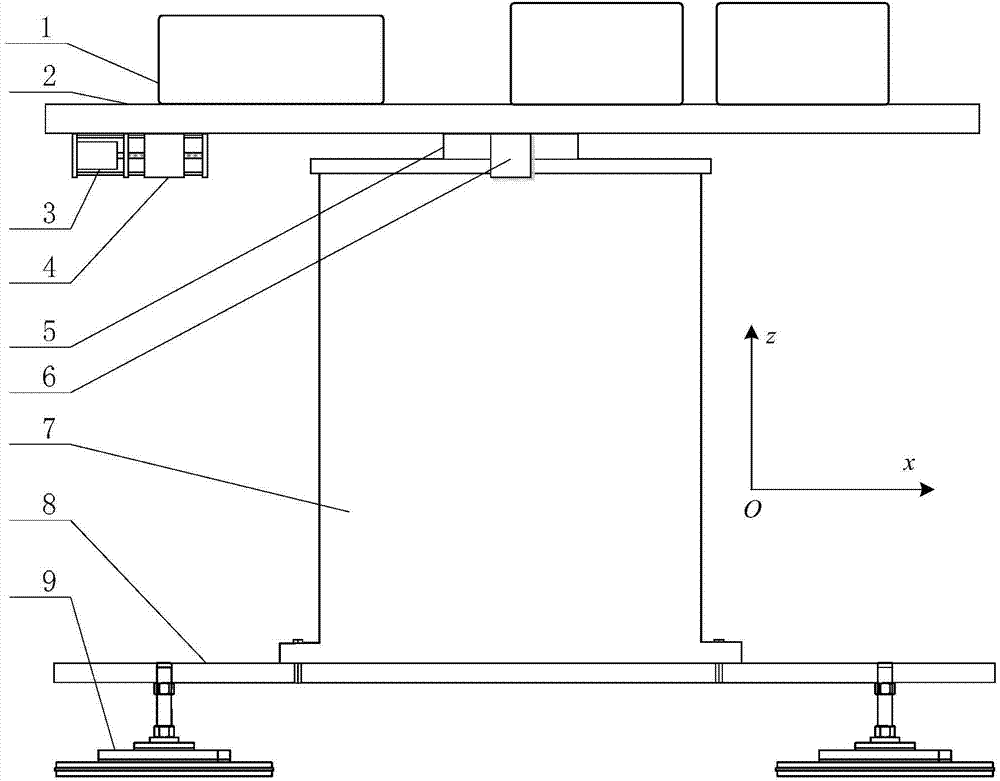

[0038] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment, the high-precision vertical air bearing turntable automatic trim device described in this embodiment is characterized in that it includes a payload 1, a load mounting plate 2, an x-axis trim motor 3, an x-axis counterweight 4, an air Floating shaft 5, y-axis trim motor 6, air-floating turntable main body 7, air-floating turntable base 8, air-floating turntable height adjustment support 9 and y-axis counterweight 10,

[0039]The payload 1 is fixedly connected to the threaded interface on the upper surface of the load mounting plate 2, and the center of the lower surface of the load mounting plate 2 is fixedly connected to the air bearing shaft 5, and the air bearing shaft 5 is correspondingly arranged at the center of the upper surface of the air bearing turntable main body 7, The bottom surface of the main body 7 of the air flotation turntable is fixedly connect...

specific Embodiment approach 2

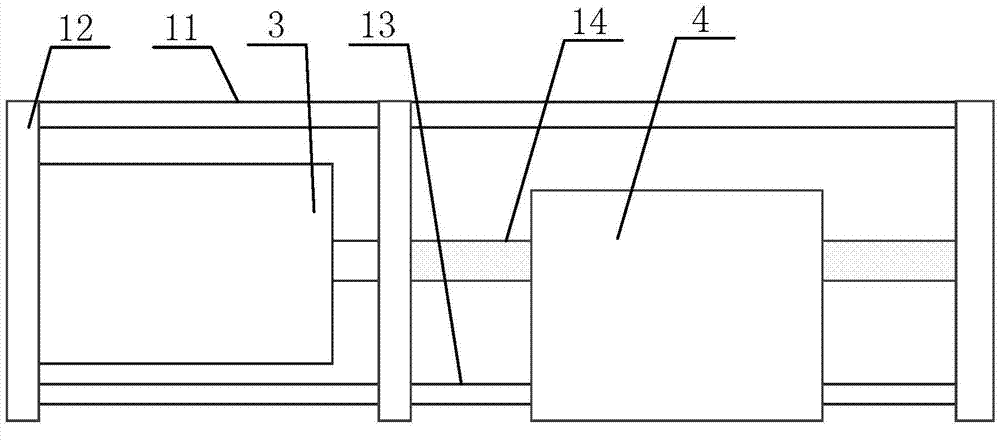

[0046] Specific implementation mode two: the following combination Figure 1 to Figure 3 This embodiment will be described. This embodiment will further describe the first embodiment. The relationship between the x-axis trim motor 3, the x-axis counterweight 4 and the load mounting plate 2 is related to the relationship between the y-axis trim motor 6, the y-axis counterweight 10 and The mutual connection relationship of the load mounting plate 2 is the same,

[0047] The x-axis trimming motor 3, the x-axis counterweight 4 and the load mounting plate 2 are connected to each other through the mounting frame. The mounting frame includes a fixed plate 11, three motor support plates 12, guide columns 13 and studs 14, and the mounting frame’s fixed plate 11 is fixed on the X-axis direction of the outer ring circumference of the lower surface of the load mounting plate 2,

[0048] The fixed plate 11, the guide column 13 and two motor support plates 12 form a square frame, and anoth...

specific Embodiment approach 3

[0050] Specific implementation mode three: the following combination figure 1 and Figure 4 This embodiment will be described, and this embodiment will further describe Embodiment 1 or 2. There are three air flotation turntable height adjustment supports 9 , which are evenly arranged along the circumferential direction of the lower surface of the air flotation turntable base 8 .

[0051] Figure 4 As shown, the height adjustment support 9 of the air flotation turntable is composed of an adjustment stud 9-1, a locking bolt 9-2, a bottom nut 9-3, a support base 9-4 and a cover plate 9-5, and the adjustment stud 9-1 It is connected with the bottom support base 9-4 by a ball hinge, and the connection between the ball hinge and the bottom support base 9-4 is realized through the cover plate 9-5, and the rotation of the bottom nut 9-3 can realize the lifting of the adjustment stud 9-1, driving the turntable Provides height and level adjustment. For a high-precision turntable with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com