A layered point color system

A layered point and color technology, applied in the field of engraving coloring, can solve the problems of large color spraying area, small area of red wine bottle, difficult to meet the requirements of pattern refinement, etc., so as to improve the qualified rate of coloring, Improve the efficiency of spotting and improve the effect of color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

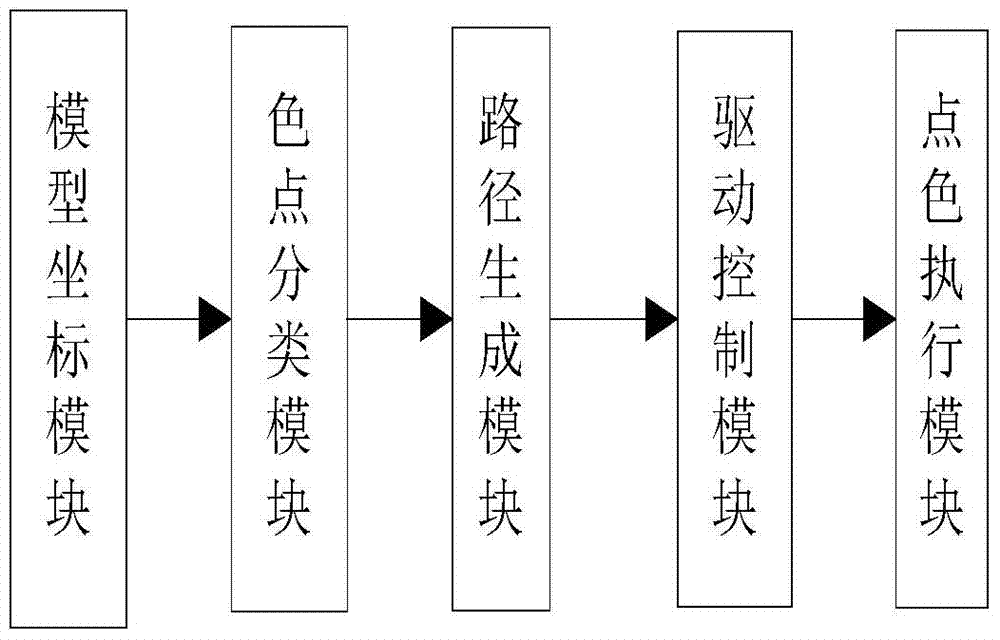

[0021] refer to figure 1 , a layered point color system proposed by the present invention includes: a model coordinate module, a color point classification module, a path generation module, a drive control module and a point color execution module.

[0022] The dot color execution module is used for coloring the embryo body to be dotted, and it can be composed of a plurality of dot color heads that can move relative to the dotted embryo body.

[0023] The model coordinate module is used to establish a coloring model, establish coordinates for each color point on the surface of the coloring model and mark the hue. The model coordinate module is also used to establish a reference plane opposite to the color model and located on the periphery of the color model, and each color point has a corresponding point on the reference plane. Specifically, the model coordinate module establishes a reference plane according to the relative motion direction of the color embryo body to be spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com