Layered vertex coloring method

A layered dot and color dot technology, which is applied in the field of engraving coloring, can solve the problems of large coloring area of color spraying, difficulty in meeting the requirements of pattern refinement, and difficulty in achieving the expected effect, so as to improve the quality of coloring rate, improve the effect of color quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

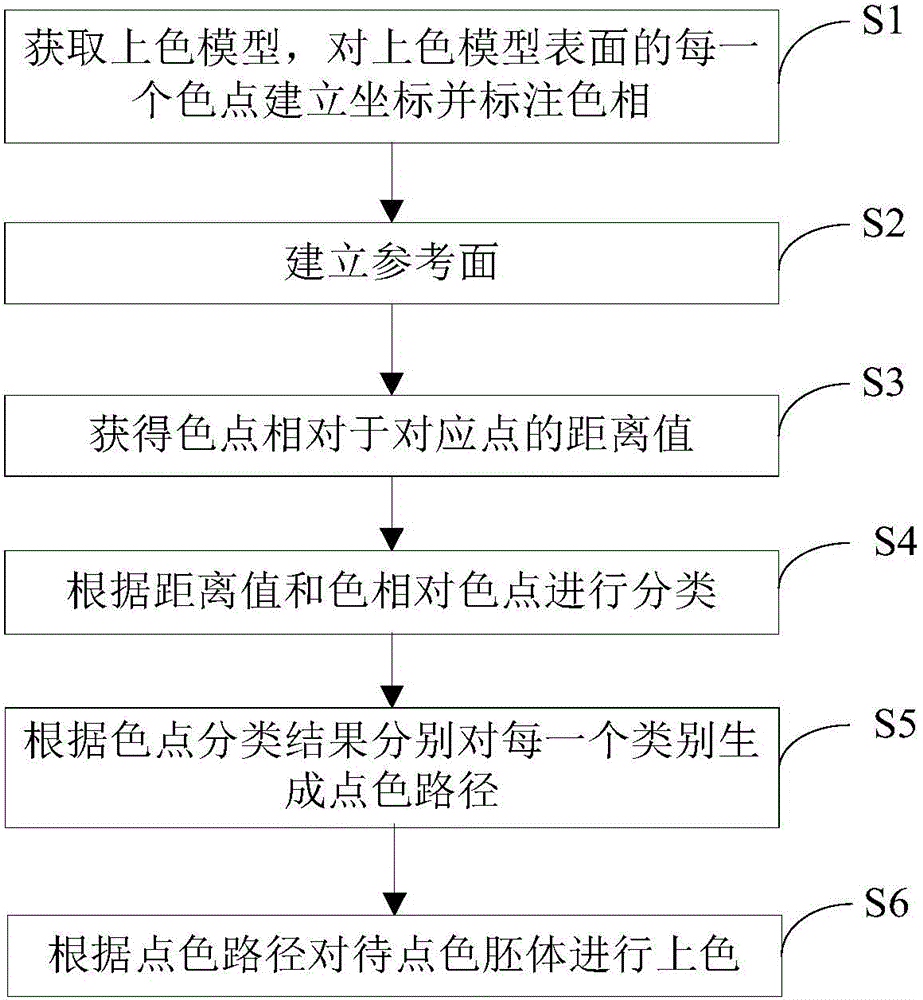

[0029] refer to figure 1 , a kind of layered point color method that the present invention proposes, comprises:

[0030] S1. Obtain the coloring model of the embryo body to be colored, establish coordinates for each color point on the surface of the coloring model and mark the hue. In this way, the surface information of the embryo body to be colored can be digitized, which is convenient for the automatic coloring work.

[0031] S2. Establish a reference plane that is set opposite to the color model and located on the periphery of the color model, and each color point has a corresponding point on the reference plane. Specifically, the reference plane is established according to the relative movement direction between the body to be spotted and the spotting nozzle, so as to determine the position of the spotting nozzle during the spotting process. After the reference plane is determined, a ray is made from each color point to the reference plane perpendicular to the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com