Production process of ultra-thin electromagnetic shielding film

A technology of electromagnetic shielding film and production process, applied in the fields of magnetic field/electric field shielding, electrical components, layered products, etc., to achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

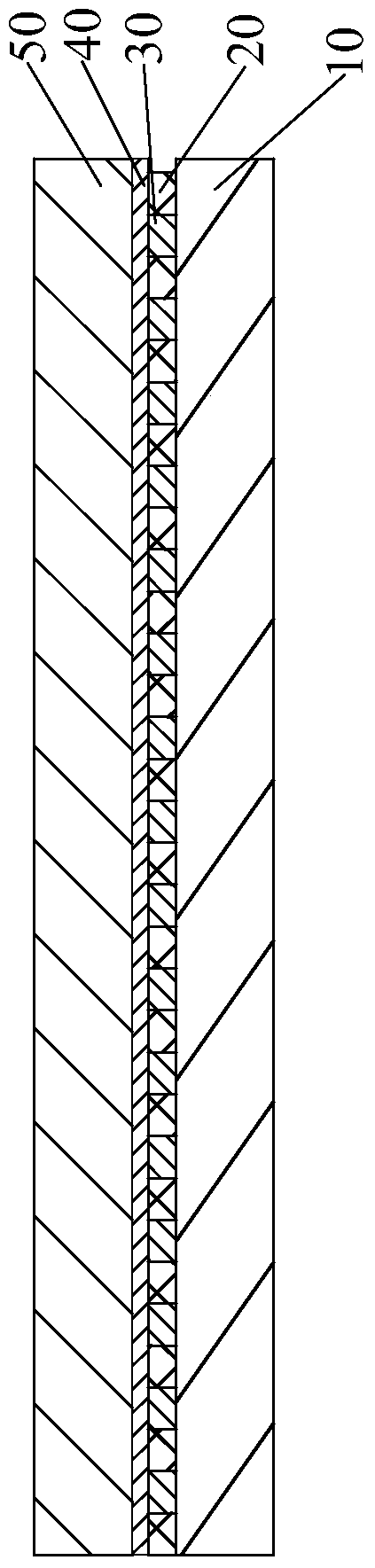

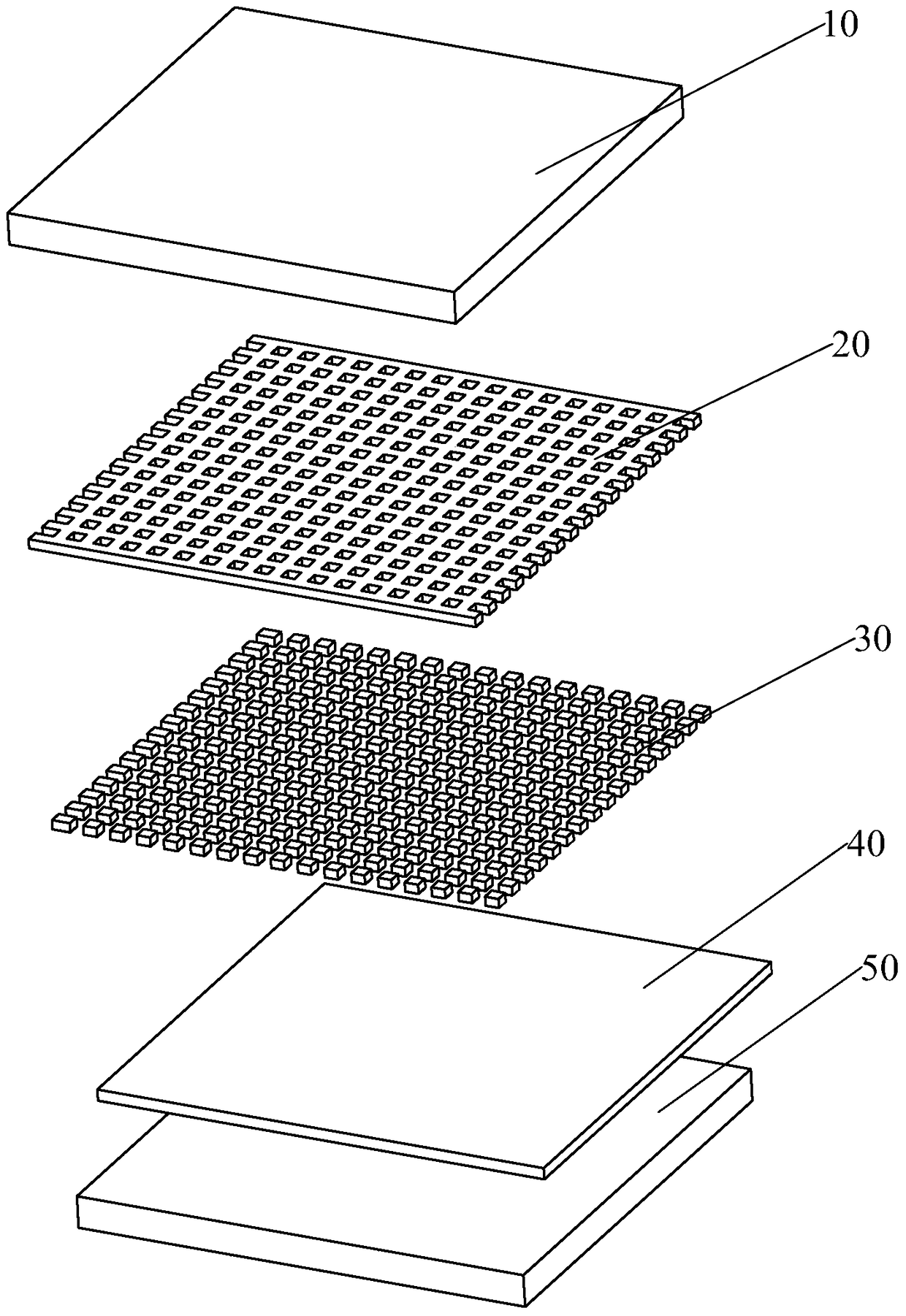

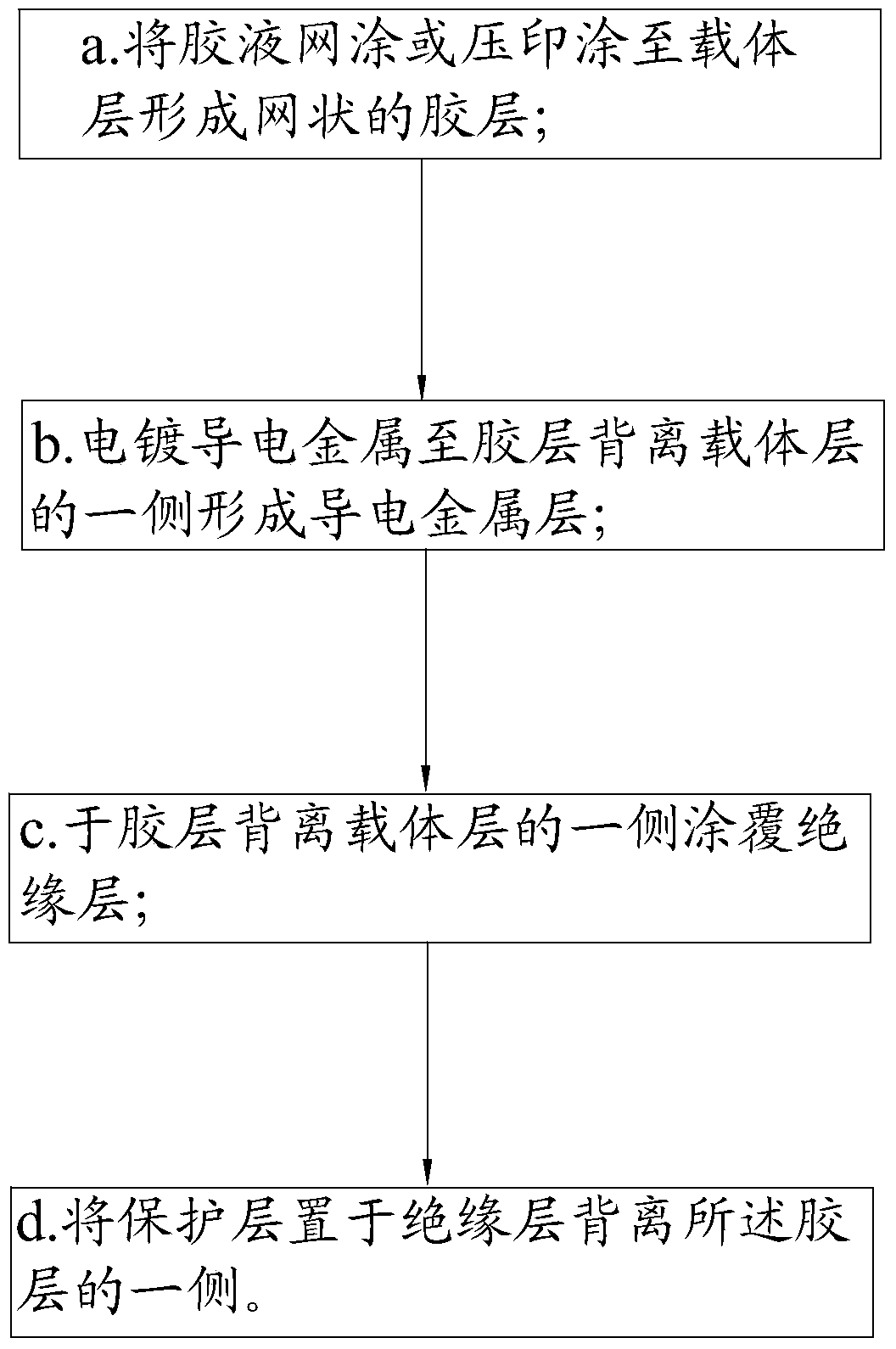

[0022] Such as figure 1 As shown, the ultra-thin electromagnetic shielding film provided by the present invention includes a carrier layer 10, an adhesive layer 20, a conductive metal layer 30, an insulating layer 40, and a protective layer 50 arranged in sequence, wherein the adhesive layer 20 is reticular, at least partially The conductive metal layer 30 is filled in the mesh pores of the adhesive layer 20 . combine figure 2 Shown, more specifically:

[0023] The carrier layer 10 has a planar structure, which can be a release film or a release paper. When the ultra-thin electromagnetic shielding film provided by the present invention is put into use, the carrier layer 10 is torn off from the adhesive layer 20, and the side of the ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com