Black conductive ink for adhesive tape as well as preparation method and application of black conductive ink

A conductive ink and black technology, applied in the field of black conductive ink for tape and its preparation, can solve the problems of reduced conductivity, poor conductivity stability, poor adhesion of ink layer, etc., and achieves remarkable effect, high shielding, high adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

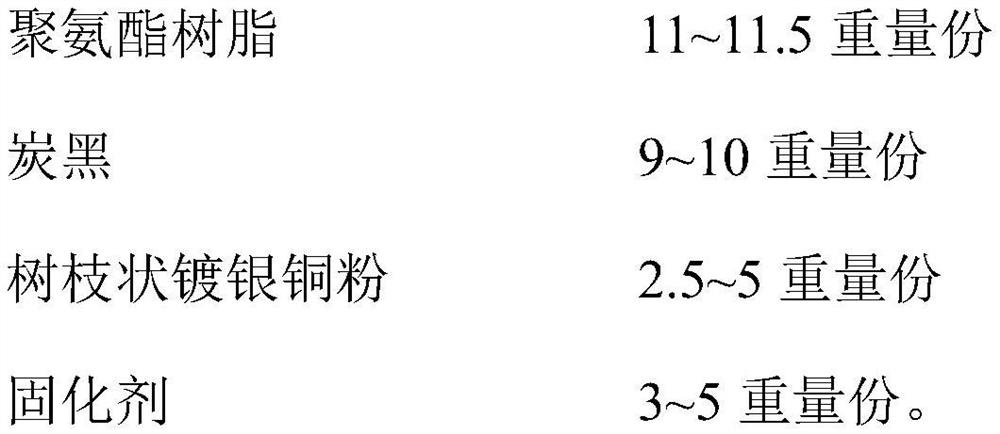

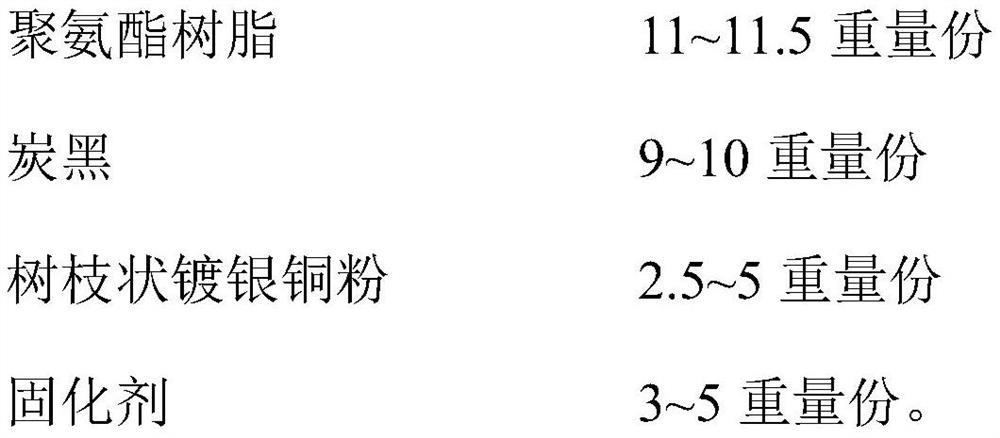

[0038] A kind of black conductive ink for adhesive tape, it comprises following component according to weight part:

[0039]

[0040]

[0041] The preparation method of the black conductive ink for adhesive tape provided in this embodiment includes: first polyurethane resin (Sanyo Chemical Industry Co., Ltd., IB-1700D) and carbon black were mixed for 60 min under stirring conditions, and dendritic silver-plated copper powder (silver powder) was added. Feng Metal Technology Co., Ltd., YF-B508) mixed for 20 minutes under the condition of stirring, then added the dispersant (Germany BYK Co., Ltd., BYK-3440) and mixed for 60 minutes under the condition of stirring, and finally added the isocyanate curing agent (caution Chemical Co., Ltd., hardener N) were mixed for 20min under stirring conditions to obtain the black conductive ink for the adhesive tape.

Embodiment 2

[0043] A kind of black conductive ink for adhesive tape, its difference with embodiment 1 is only, wherein the addition amount of dendritic silver-plated copper powder is 3 weight parts, other components, consumption and preparation method are all identical with embodiment 1.

Embodiment 3

[0045] A kind of black conductive ink for adhesive tape, its difference with embodiment 1 is only, wherein the addition of dendritic silver-plated copper powder is 5 weight parts, other components, consumption and preparation method are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com