Seed ditch crushing soil suppressor

A compactor and soil crushing technology, applied in agricultural machinery and implements, agriculture, shovels, etc., can solve problems such as difficulty in forming coverage quality and consistency of sowing depth, inability to form a soil environment in the plough layer, and reduction in dry matter accumulation, etc. Improve the coverage quality and the consistency of sowing depth, improve the operation effect and stability, and have the effect of strong anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

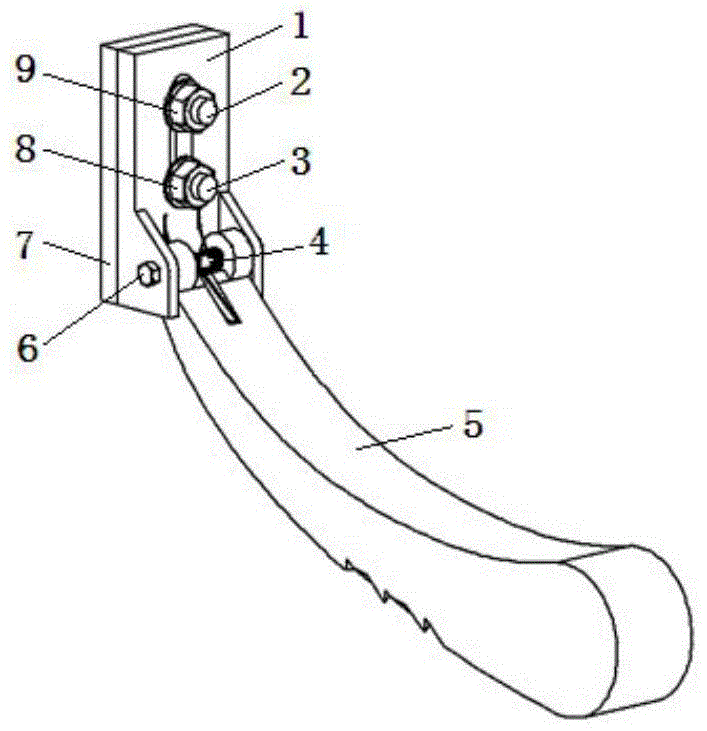

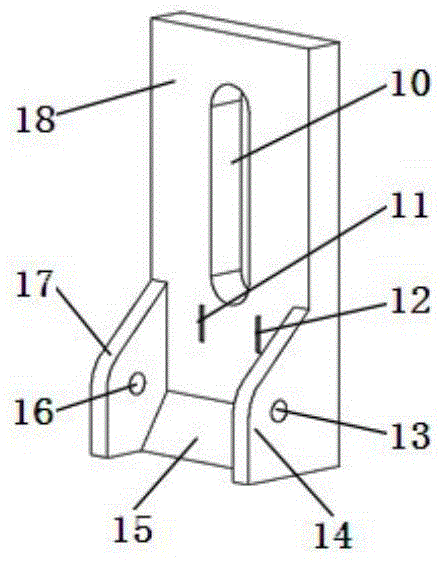

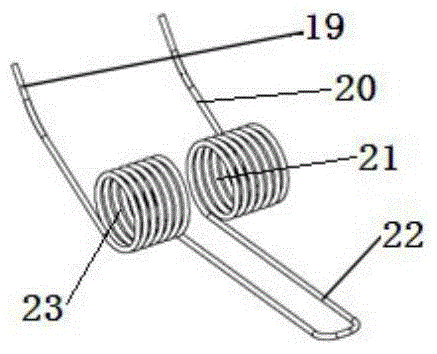

[0039] Such as figure 1 As shown, in the present invention, the middle part of the bolt III6 is flexibly connected with the through hole IV35 and the through hole III31 of the crushing soil suppression arm 5, and the two ends of the bolt III6 are fixedly connected with the through hole II16 and the through hole I13 of the connecting frame 1; parallel double torsion springs The coil II 23 and coil I 21 of 4 are flexibly connected to the central part of the bolt III 6, the middle torsion arm 22 of the parallel double torsion spring 4 is limited by the groove 34 of the crushing arm 5, and the side of the parallel double torsion spring 4 The torsion arm I19 and the side torsion arm II20 are respectively limited by the groove I11 and the groove II12 of the connecting frame 1; one end of the bolt I2 is fixedly connected to the plate 7, and the other end of the bolt I2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com