Lead-acid battery grid double-sided pasting mechanism by adopting reciprocating buffering principle

A lead-acid battery and grid technology, used in lead-acid batteries, lead-acid battery electrodes, lead-acid battery construction, etc., can solve the problems of inability to ensure uniform coating surface, uneven overall range, and inadequate coverage, and achieve Improve the coverage of raw materials, improve the quality of paste, and ensure the effect of equal distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

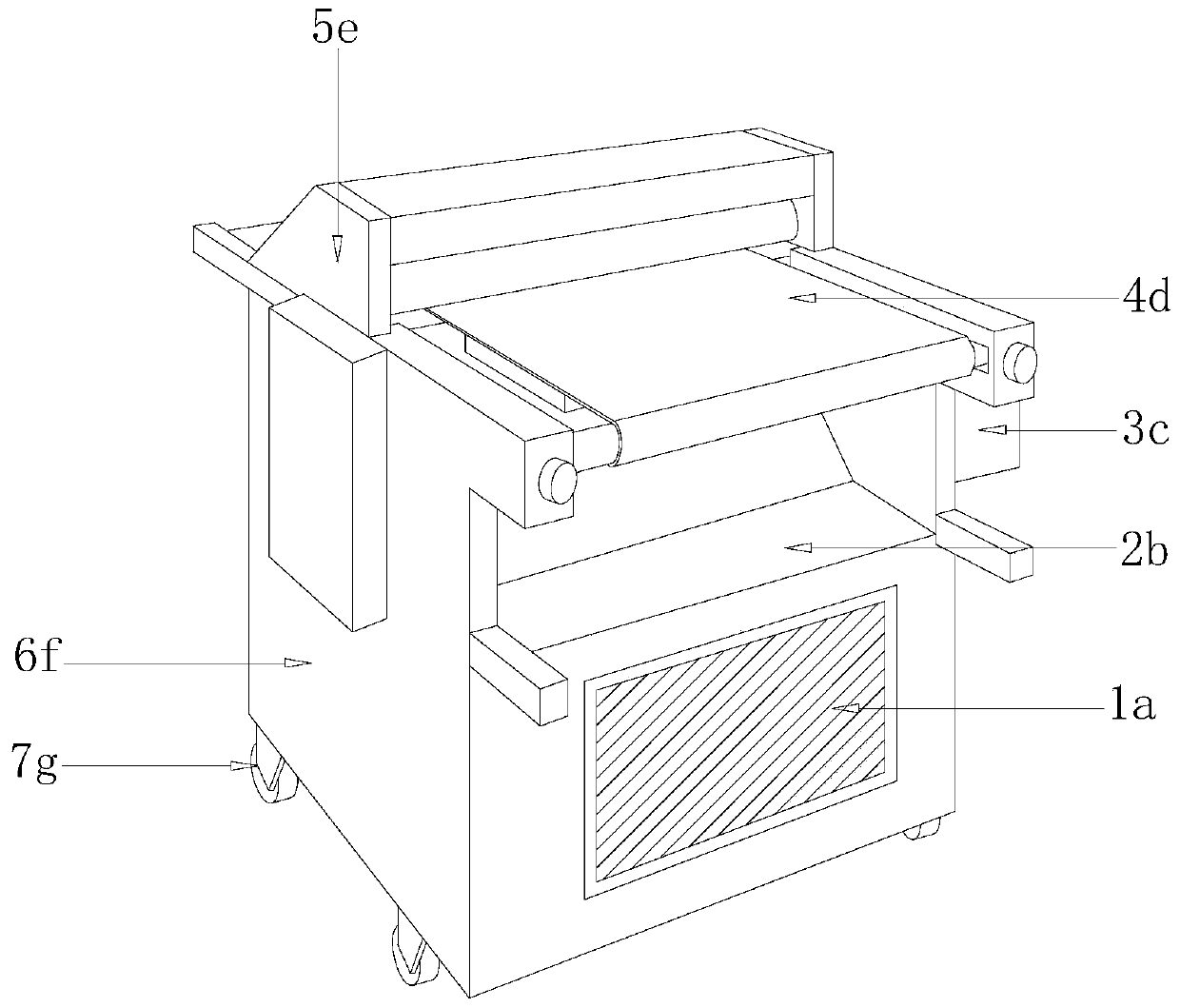

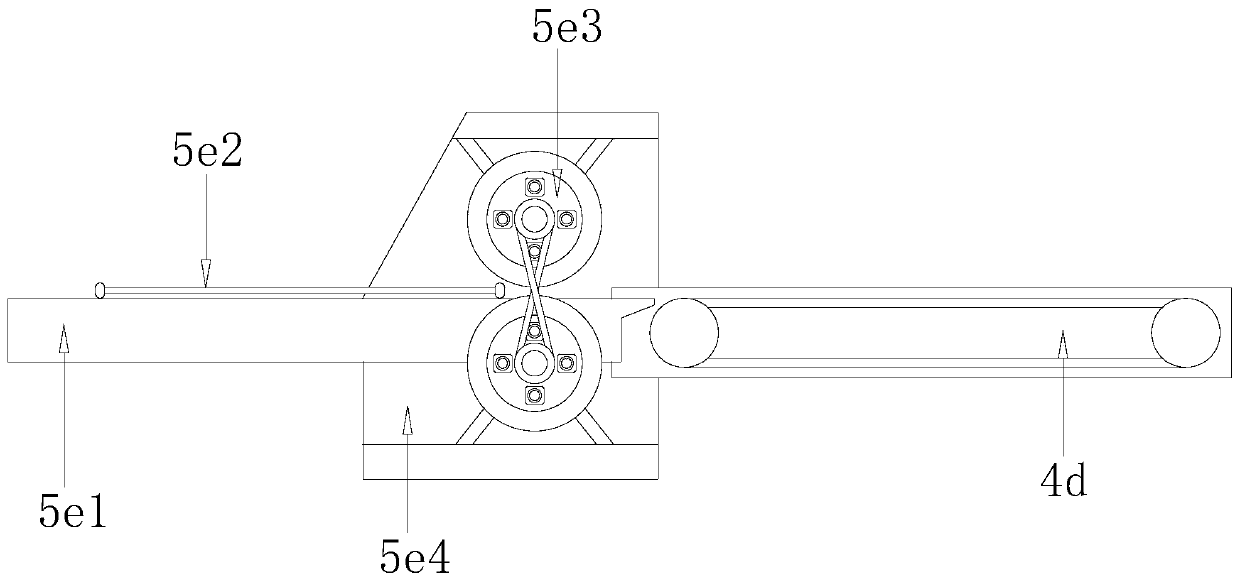

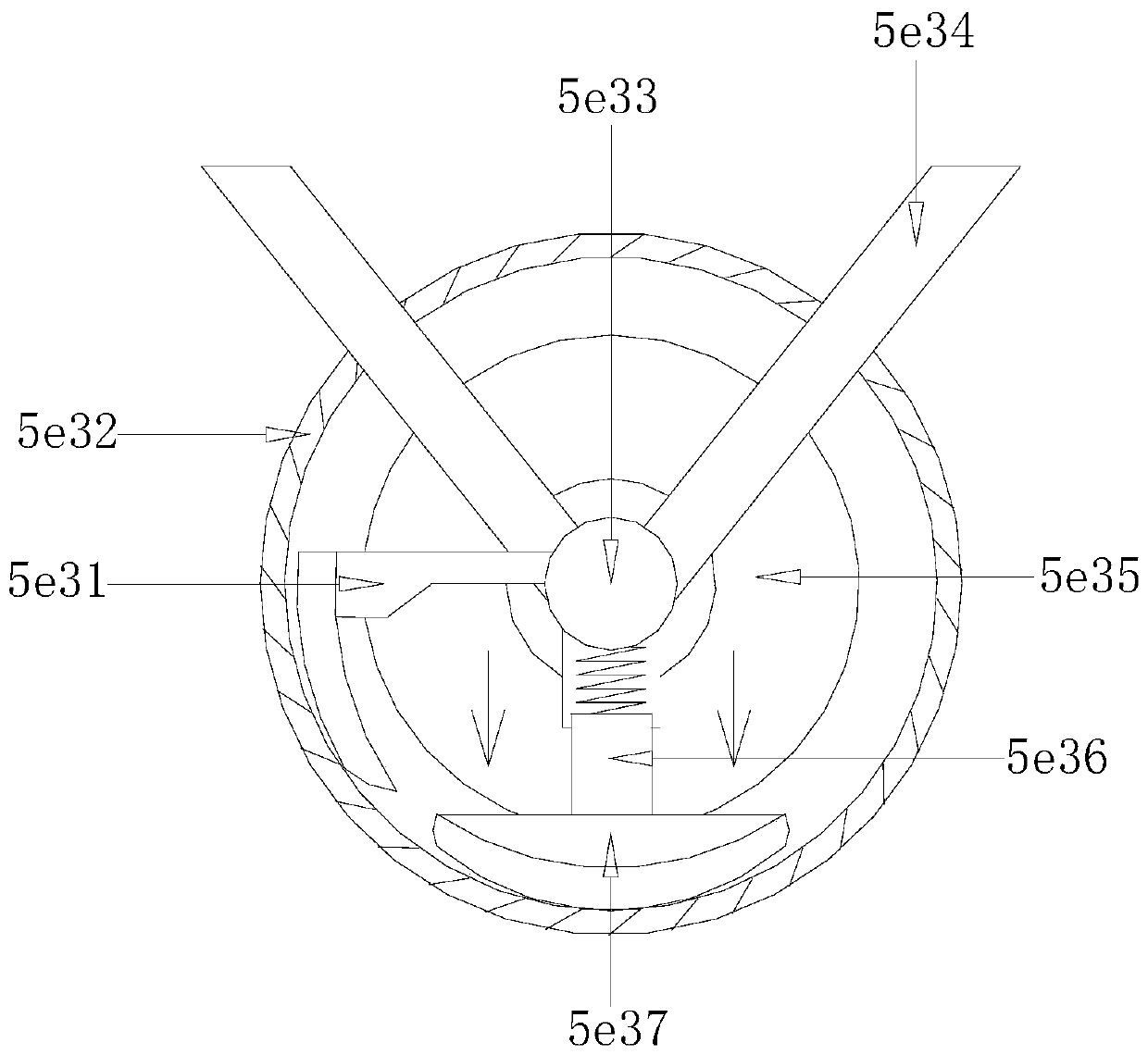

[0031] see Figure 1-Figure 7 , the present invention provides a double-sided plastering mechanism for lead-acid battery grids that adopts the principle of reciprocating buffering. Main frame 6f, universal wheel 7g, said universal wheel 7g is provided with four, and is installed on the bottom of equipment main frame 6f by snap-fitting mode, and said equipment main frame 6f top middle position is provided with plaster cross arm 5e, and said conveying The belt 4d is installed on the upper end of the equipment main body 6f by buckling. The upper surface of the equipment main body 6f is provided with a storage compartment 2b, which is an integrated structure. The lower surface of the storage compartment 2b is provided with a heat sink for movable installation. 1a, the controller 3c is installed on the upper right side of the equipment host 6f by buckling, the equipment host 6f is started by the controller 3c, and the plastering cross arm 5e is used for plastering and transporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com