Tread pattern structure of air-filled tyre used for motorcycle

A technology for pneumatic tires and tread patterns, applied in tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problem of inability to effectively improve cornering traction performance, reduce drainage performance, and low block edge components. problems, to improve traction performance and wet grip performance, ensure guidance and drainage performance, and improve the effect of edge components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

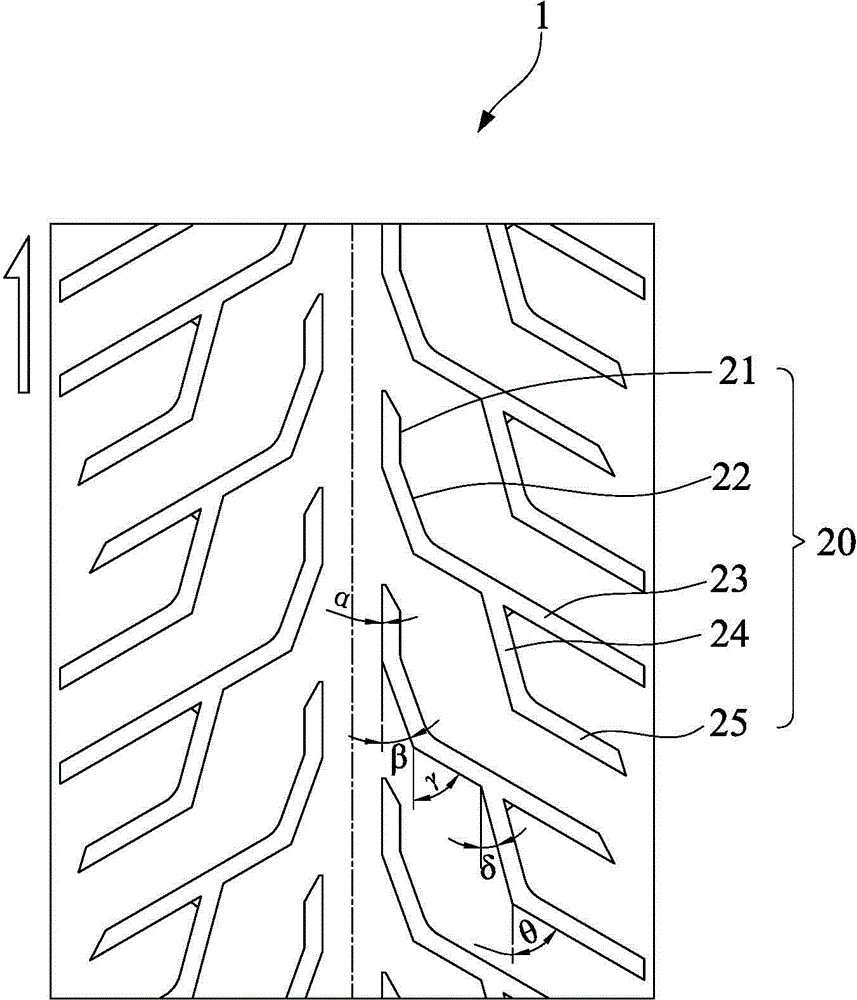

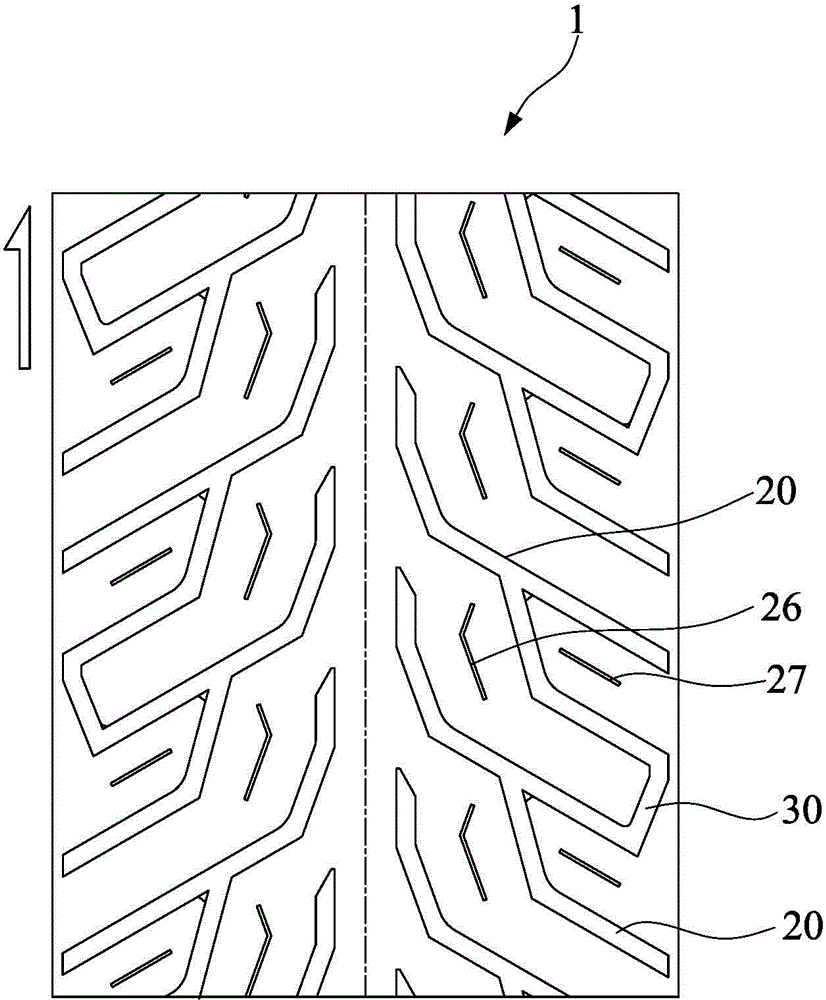

[0022] Such as Figure 2 to Figure 5 As shown, the present invention discloses a tire tread pattern structure for a large scooter. The tire tread 1 includes several pattern units that are symmetrical and staggered with the center line of the tread. Two "h"-shaped pattern main grooves 20 are arranged towards and inclined, wherein the long sides of the "h"-shaped pattern main grooves 20 include extending from the center of the tread to the shoulders, and the inclination angle relative to the center line of the tread is gradually reduced. Large first fold line groove 21, the second fold line groove 22 and the third fold line groove 23, the fourth fold line groove 24 and the fifth fold line groove 25 constitute the horizontal side and the short side of the "h" shape, and the fourth fold line groove 24 runs through the first fold line groove. The third fold line groove 23 and the fifth fold line groove 25; the fourth fold line groove 24 and the fifth fold line groove 25 also extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com