Cold and hot cycle treatment method for high-speed train car body structural materials

A technology of cold and hot cycle treatment and car body structure, which is applied in the field of strengthening and toughening technology of aluminum alloy welded joints, can solve problems such as poor impact toughness, achieve the goals of improving tensile strength, precise temperature control, and eliminating cold and brittle phenomena Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

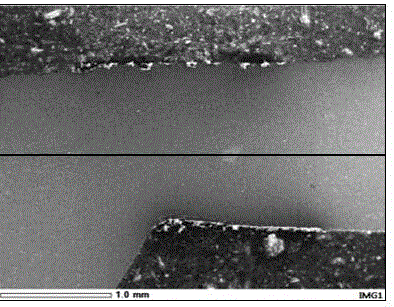

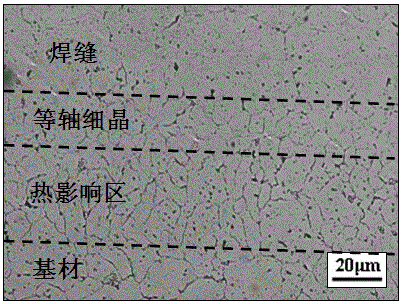

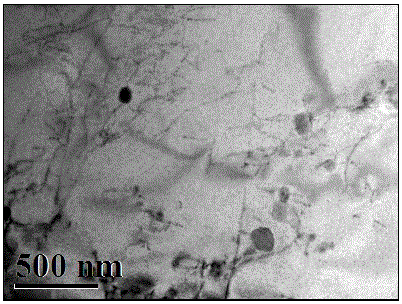

Image

Examples

Embodiment 1

[0030] Embodiment 1: 6XXX series aluminum alloys are subjected to 1 cooling and heating cycle treatment, including the following process steps:

[0031] Put the 3mm×20mm×100mm 6005A aluminum alloy welded joint thin plate workpiece into a crucible resistance furnace at 410~430℃ for 2~5 hours for homogenization annealing treatment, take it out and slowly cool down to room temperature; then put it in an ultra-low temperature deep In the freezer, first keep warm at -40~-60°C for 30~50 minutes; then continue cooling to the range of -160~-180°C at a cooling rate of 15°C / min, and keep warm for 6~8 hours; then warm to -40~ Insulate at -60°C for 30~50 minutes, then take the workpiece out of the deep freezer, place it in the air and let it warm up to room temperature naturally, and let it stand for 1~2 hours; Strength increased from 190.95MPa to 211.65Mpa, impact toughness increased from 28.1J cm -2 Increased to 33.4 J cm -2.

Embodiment 2

[0032] Embodiment 2: 6XXX series aluminum alloys are subjected to 2 cold and hot cycle treatments, including the following process steps:

[0033] (1) Put the 3mm×20mm×100mm 6005A aluminum alloy welded joint thin plate workpiece into a crucible resistance furnace at 410~430℃ for 2~5 hours for homogenization annealing treatment, take it out and slowly cool down to room temperature; then put it In an ultra-low temperature deep freezer, keep warm at -40~-60°C for 30~50 minutes; then continue cooling to -160~-180°C at a cooling rate of 15°C / min, and keep warm for 6~8 hours; then heat to - Keep warm at 40~-60°C for 30~50 minutes, then take the aluminum alloy workpiece out of the deep freezer, place it in the air and let it warm up to room temperature naturally, and let it stand for 1~2 hours.

[0034] (2) Put the aluminum alloy workpiece into the deep freezer and repeat the operation of step (1), that is, complete the two cold and hot cycle cryogenic treatments of the aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com