A hard seal ball valve with guide rail

A technology of hard sealing and ball valves, which is applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., which can solve the problems of disc and seat wear, reduced sealing performance, and affecting normal use, so as to achieve good sealing performance and reduce Wear and improve the effect of work continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

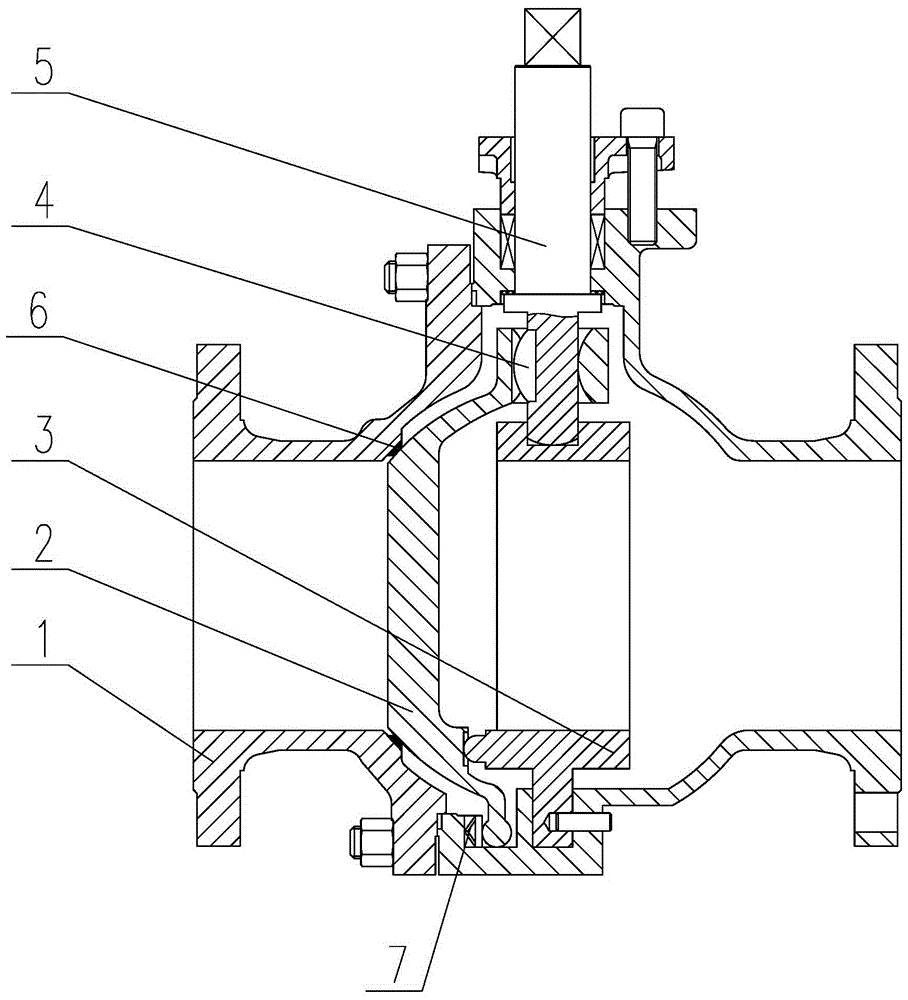

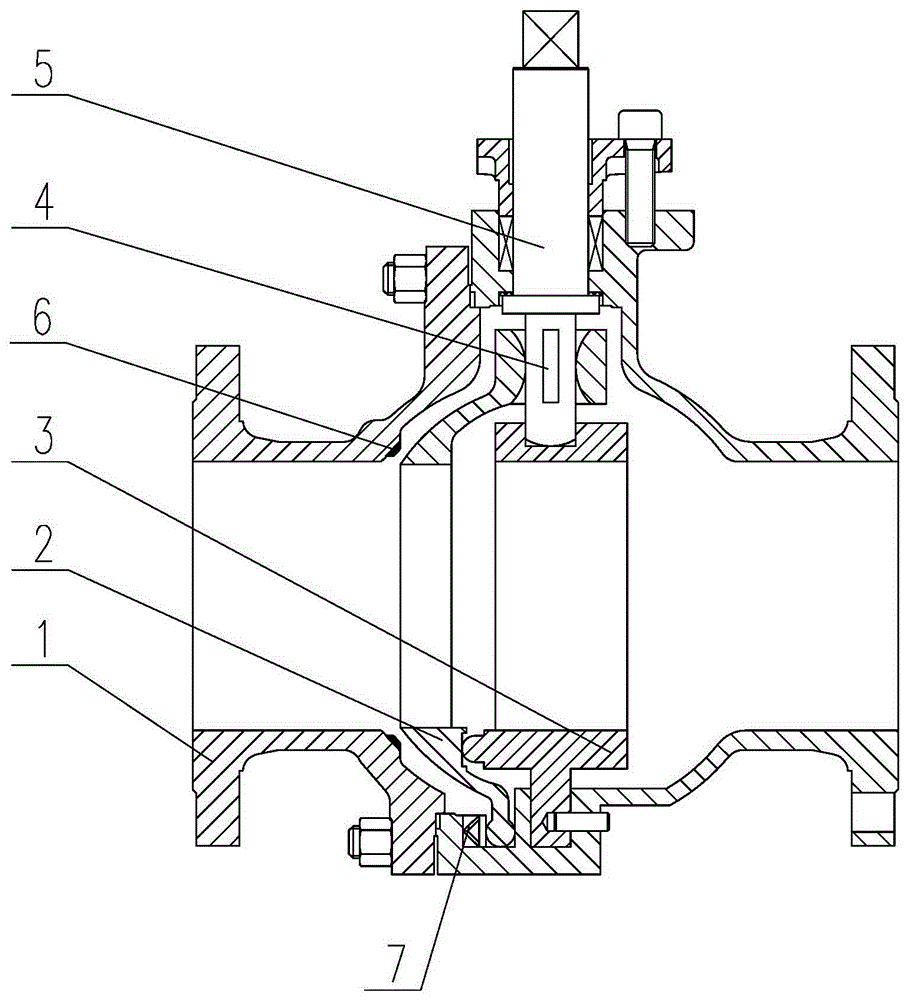

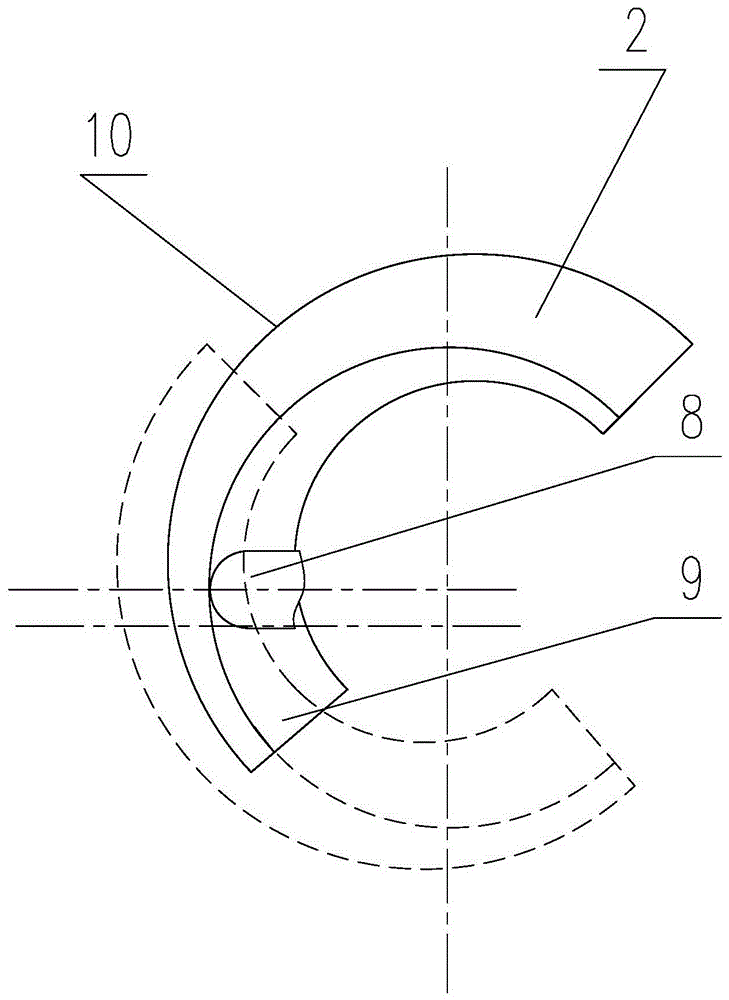

[0013] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The hard-sealed ball valve with guide rail includes a valve body 1, a valve stem 5 and a valve seat 6. The valve body 1 is divided into a left valve body and a right valve body. The upper end of the valve stem 5 is provided with a handwheel. A fluid channel, the fluid channel is provided with a valve flap 2 and an inner channel ring 3, the valve flap 2 and the valve seat 6 are hard-sealed, preferably the valve seat 6 is formed by overlay welding on the wall of the fluid channel; the valve flap 2 is a hemisphere body, and the outer surface of the valve disc 2 is provided with a spherical sealing surface 10 matching the valve seat 6, and the sealing surface is made of hard sealing material, which is the prior art and will not be described in detail here; the inner surface of the valve disc 2 is provided with Rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com