Fire monitor for high-rise building

A technology for high-rise buildings and fire monitors, applied in the field of fire monitors, can solve the problems of many flammable and explosive gases, difficult to control the hit rate, unexpected dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] like Figure 8 As shown in Comparative Example a, the slide bar 52 rotatably connected to the top of the guide wheel 6, the fins 51 and the corresponding position of the guide wheel 6 defines a cam groove 61; an outer periphery of the guide wheel 6 is wound around the elastic cord 62, the resilient after the wheel 62 and cord lead-out groove portions 61 fixedly connected end.

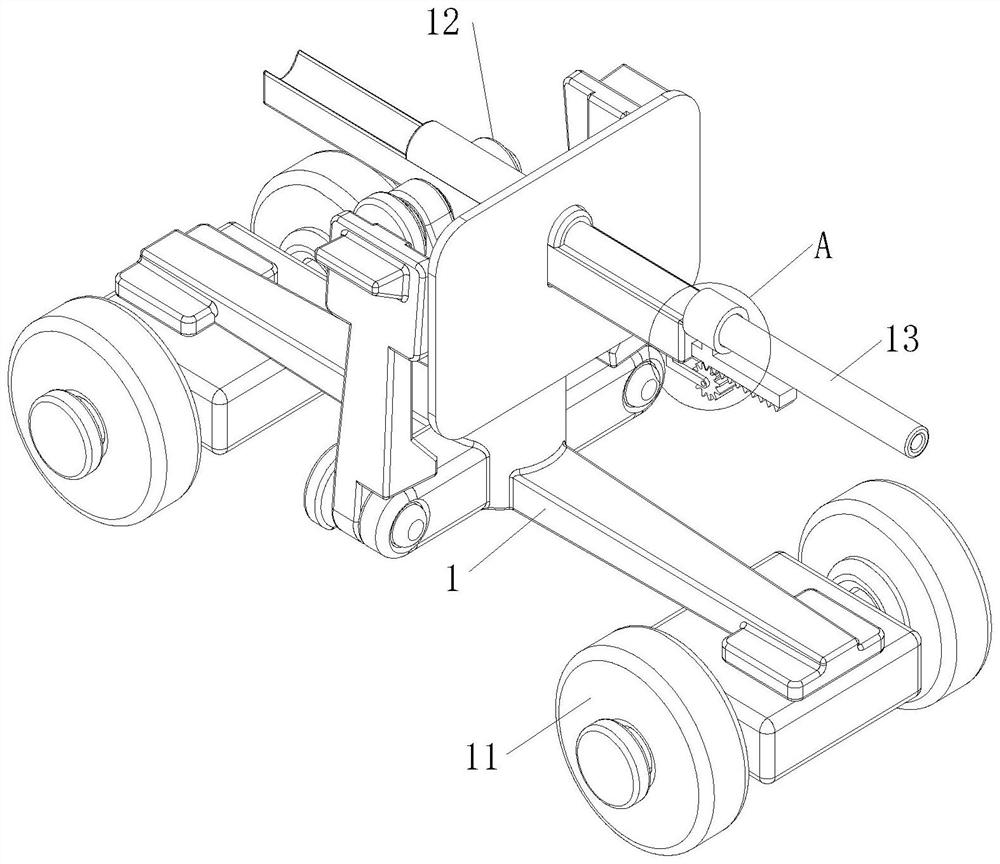

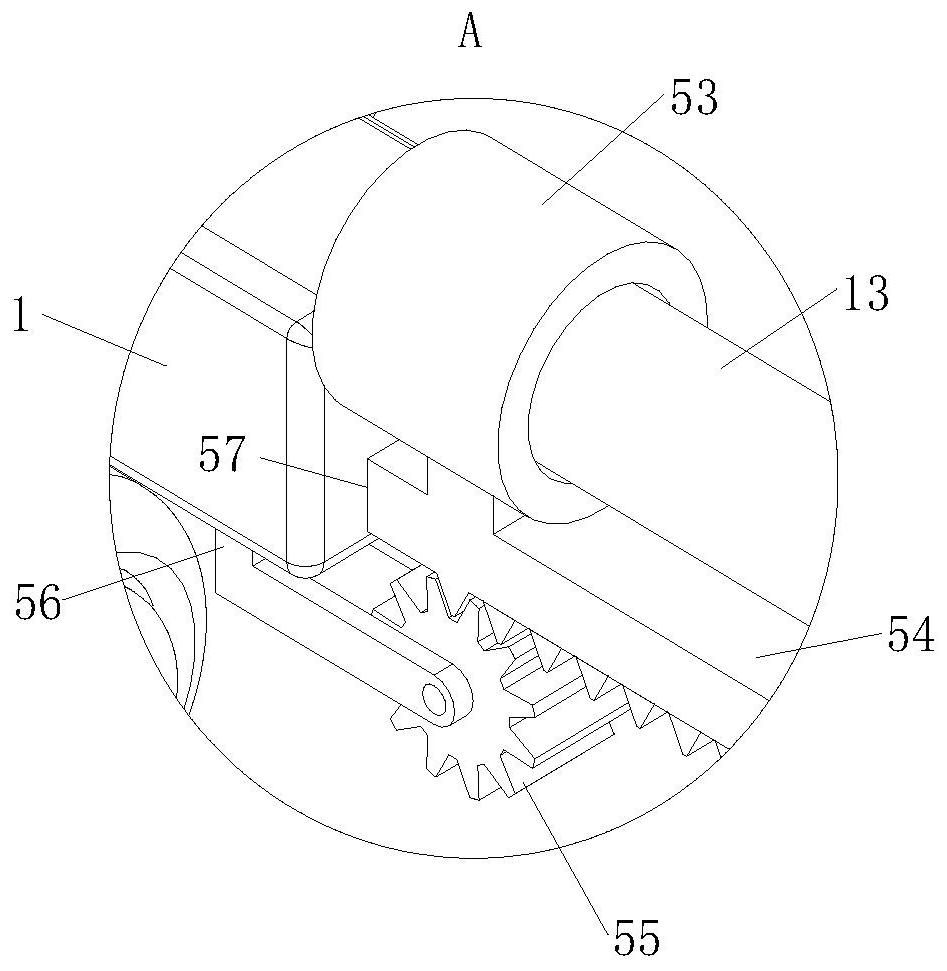

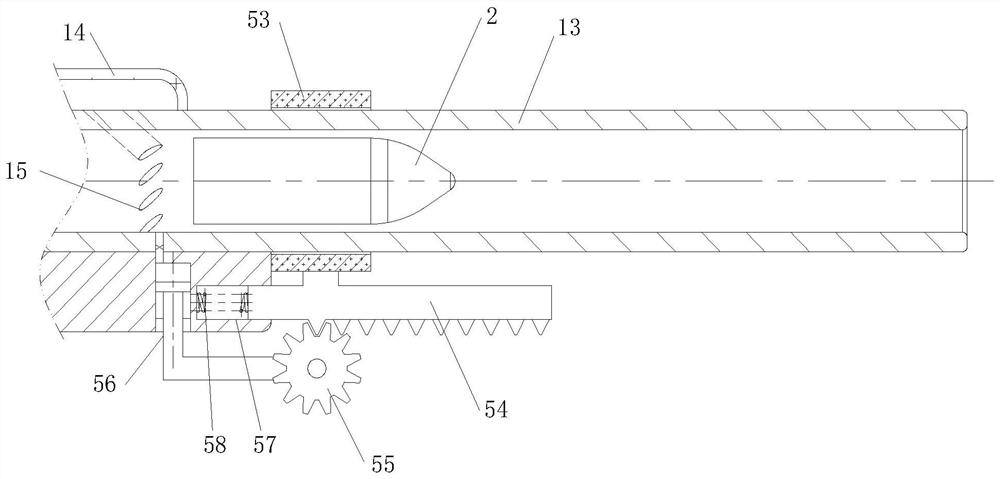

[0044]When working, the present invention is inflated into the intake pipe 14 by a high pressure gas source, and then the compressed air is sprayed into the barrel 13, driving the shells 2, while the blowing leaf 21 increases the shell 2 Spin, further enhance the operating stability of the shell 2, increase the predictive precision of the projectile 2 trajectory, thereby increasing the fire extinguishing precision of the shells 2 precipitated; when the intake hole 15 is charged into the barrel 13, Partial compressed air is used to emission the shells 2, and the other part of the compressed air is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com