High-pressure-resistant visible automatic compaction model

A technology of automatic compaction and high pressure resistance, applied in teaching models, educational appliances, instruments, etc., can solve the problems of filling sand and gravel that cannot be fully compacted, affecting experimental results and results, and inability to realize visualization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

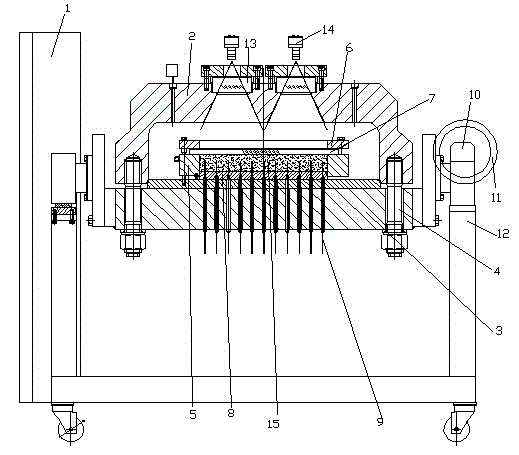

[0010] A high-pressure-resistant visual automatic compaction model, the model includes a high-pressure cavity and a visual model, the high-pressure cavity is connected to the rotary movement mechanism, and the control box 1 is arranged on the rotary movement mechanism, The upper part of the high-pressure cavity is provided with an observation device, and the visual model is set in the high-pressure cavity. The high-pressure cavity includes a cavity 2 and an end cover 3, and the cavity 2 and the end cover 3 are connected by bolts. 4 connection; the visual model includes model main body 5, pressing plate 6, high-pressure glass 7, seal, piston pressing plate 8 and detection sensor 9, and described pressing plate 6 is connected on model main body 5 tops, and described high-pressure glass 7 It is arranged between the pressing plate 6 and the model main body 5, the test sample 16 is arranged on the model main body 5, the piston pressing plate 8 is arranged at the bottom of the test s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com