Transformer breather

The technology of a respirator and a transformer is applied to the transformer respirator. It can solve the problems of abnormal positive and negative pressure of transformer oil conservator, loss of protection function, pollution of transformer oil, etc., and achieve the effect of simple structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

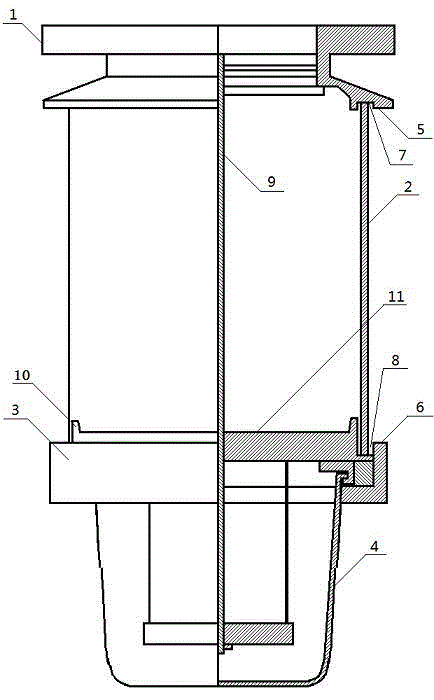

[0012] Such as figure 1 As shown, the present invention is composed of upper flange (1), glass cover (2), silica gel, base (3), oil cup (4) and the like. The outer periphery of the upper flange ⑴ and the base ⑶ are inlaid grooves ⑺ and ⑻ for the glass cover ⑵ on the inner side of the outer periphery ⑸ and ⑹. There is a sealing rubber pad in the groove, and the glass cover is inlaid between the upper flange and the base with built-in silica gel. An oil cup (4) is arranged at the lower part of the base, and a breathing hole through which the upper and lower parts are connected is arranged on the base. The above-mentioned components are connected as a whole by the through-hole screw ⑼.

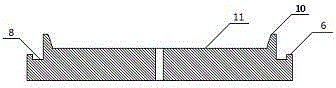

[0013] Such as figure 2 As shown, the upper surface ⑾ of the base ⑶ provided with breathing holes is higher than the height of the outer periphery ⑹ of the base, and a water retaining edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com