OLED array substrate, production method thereof, OLED display device

A technology for array substrates and manufacturing methods, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of reducing the area of the opening area, occupying, and reducing the aperture ratio of OLED display devices, so as to improve uniformity and reduce IRdrop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] An embodiment of the present invention provides an OLED array substrate, which can reduce the IR drop of the first electrode without reducing the aperture ratio of the OLED display device.

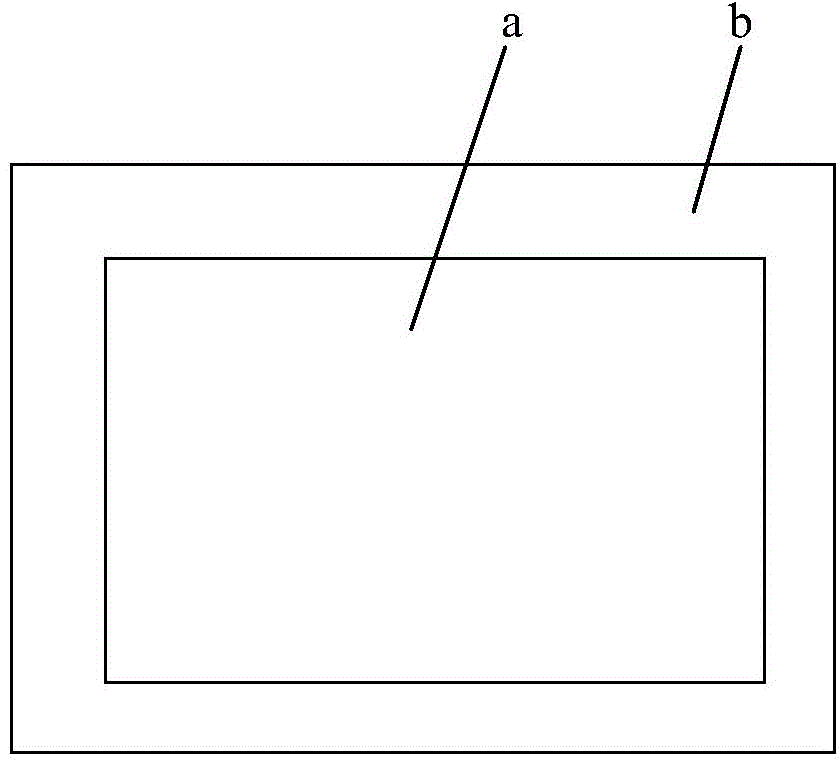

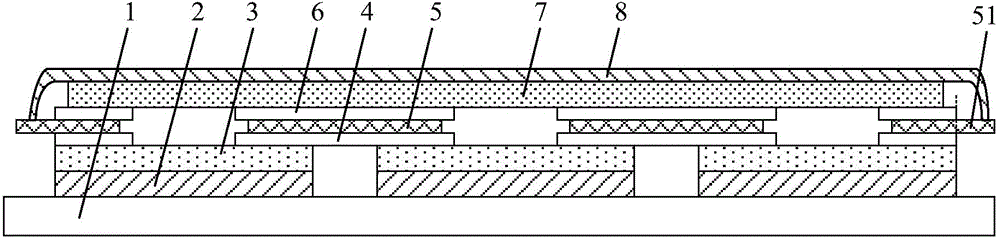

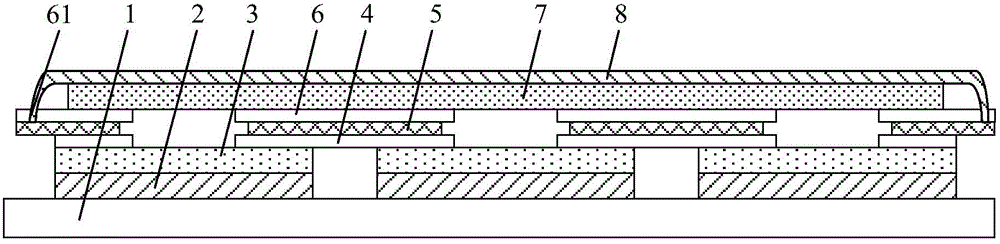

[0051] Specifically, such as figure 1 and figure 2 As shown, the OLED array substrate (hereinafter referred to as the array substrate) includes a plurality of first pixel definition layers 4, a first electrode 8, and a conductive layer 5 between the plurality of first pixel definition layers 4 and the first electrodes 8, Inside the display area a, the vertical projection of the plurality of first pixel definition layers 4 on the array substrate covers the vertical projection of the conductive layer 5 on the array substrate, and outside the display area b, the first electrode 8 and at least one conductive layer 5 are electrically connected connect. Exemplarily, the plurality of first pixel definition layers 4 in the embodiment of the present invention are arranged in a plane and c...

Embodiment 2

[0070] An embodiment of the present invention provides a method for manufacturing the OLED array substrate (hereinafter referred to as the array substrate) described in Embodiment 1. Specifically, the method includes: forming a plurality of first pixel definition layers 4; forming At least one conductive layer 5 and forms a first electrode 8 . Wherein, the conductive layer 5 is located between a plurality of first pixel definition layers 4 and the first electrodes 8; and inside the display area a, the vertical projection of the first pixel definition layer 4 on the array substrate covers the conductive layer 5 on the array substrate In the vertical projection of , the first electrode 8 is electrically connected to the conductive layer 5 outside the display area b.

[0071] Therefore, the array substrate manufactured by the above manufacturing method can reduce the IR drop of the first electrode 8 and improve the uniformity of the display screen of the OLED display device, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com