Intelligent wheel hub spraying device and control method thereof

A technology of spraying device and wheel hub, applied in the direction of spraying device, etc., can solve the problems of difficulty in precise control of spray paint film thickness, inability to adapt to large-scale production, threats to workers' health, etc., so as to improve work efficiency and spraying quality, save manpower and cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

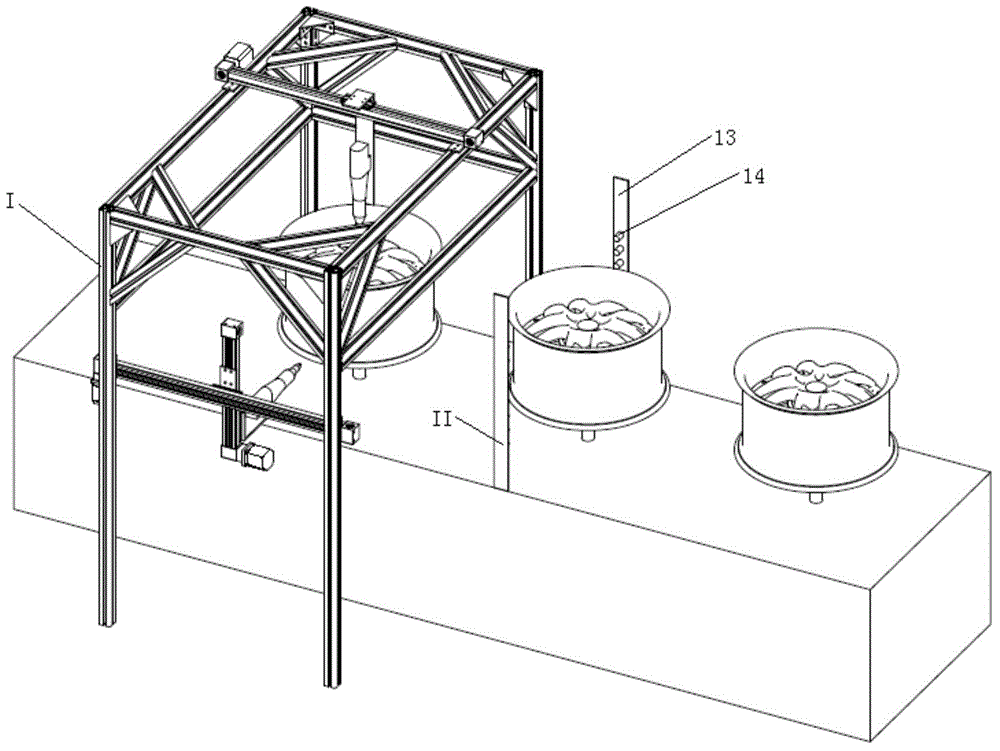

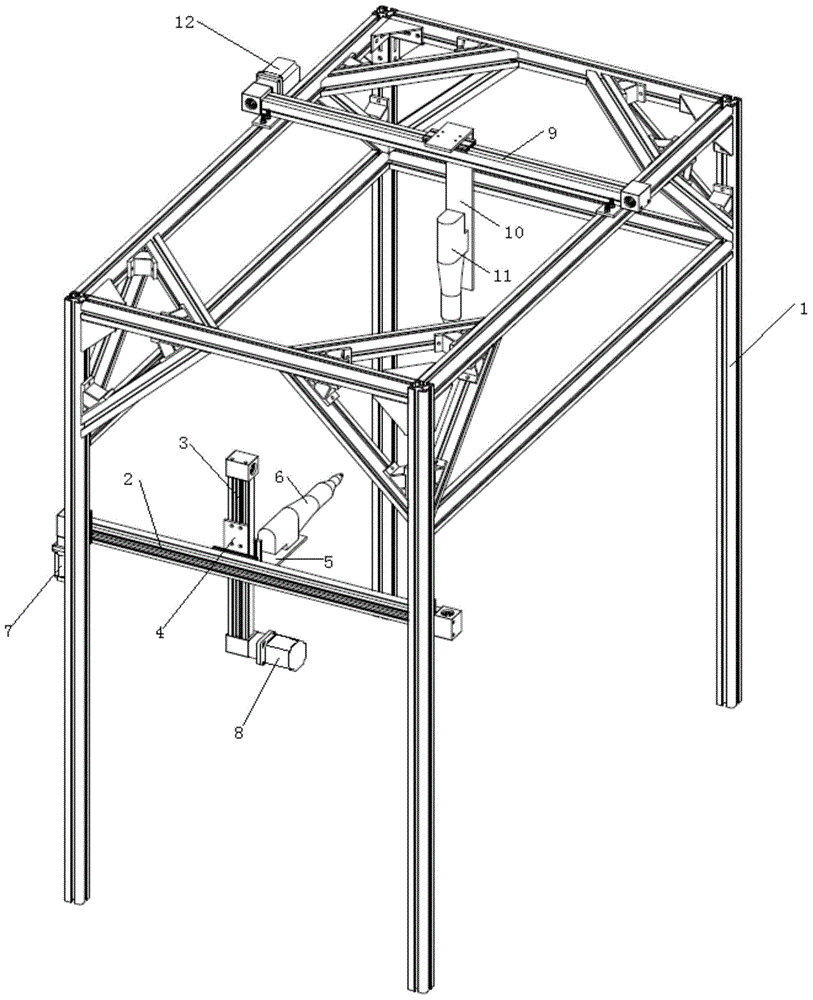

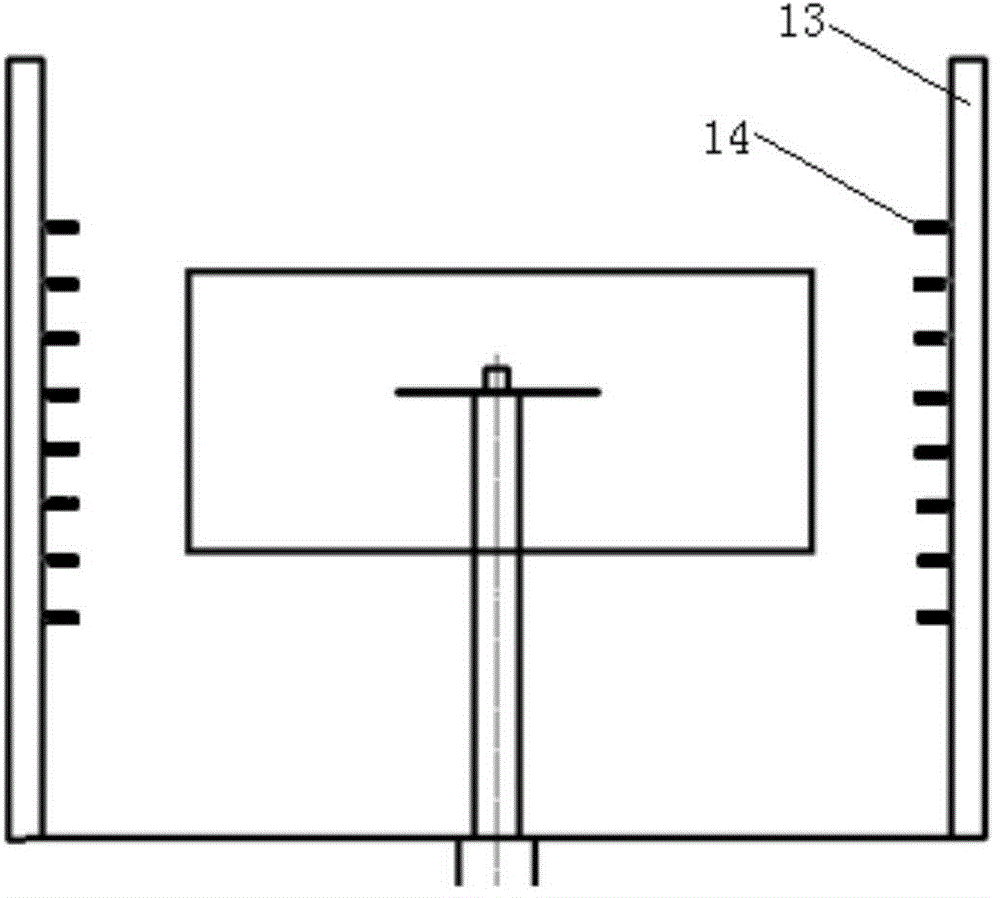

[0033]An intelligent hub spraying device comprises a spraying machine I and a detection control device II, the detection control device II is located in front of the spraying machine I, and the spraying machine I includes a frame 1, a side spraying device and a top spraying device, the The side spray device is arranged on the side of the frame 1, and the top spray device is arranged on the top of the frame; the detection control device II includes a detection frame body 13, a photoelectric switch group and a PLC controller, and the detection frame body 13 is located on the frame. 1, a photoelectric switch group 14 is arranged on the detection frame body 13, and the PLC controller is connected with the photoelectric switch group 14, the side spray device and the top spray device, receives the detection signal transmitted by the photoelectric switch group 14 and controls the side spray device, Top spray unit works. Described side spray device comprises horizontal synchronous bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com