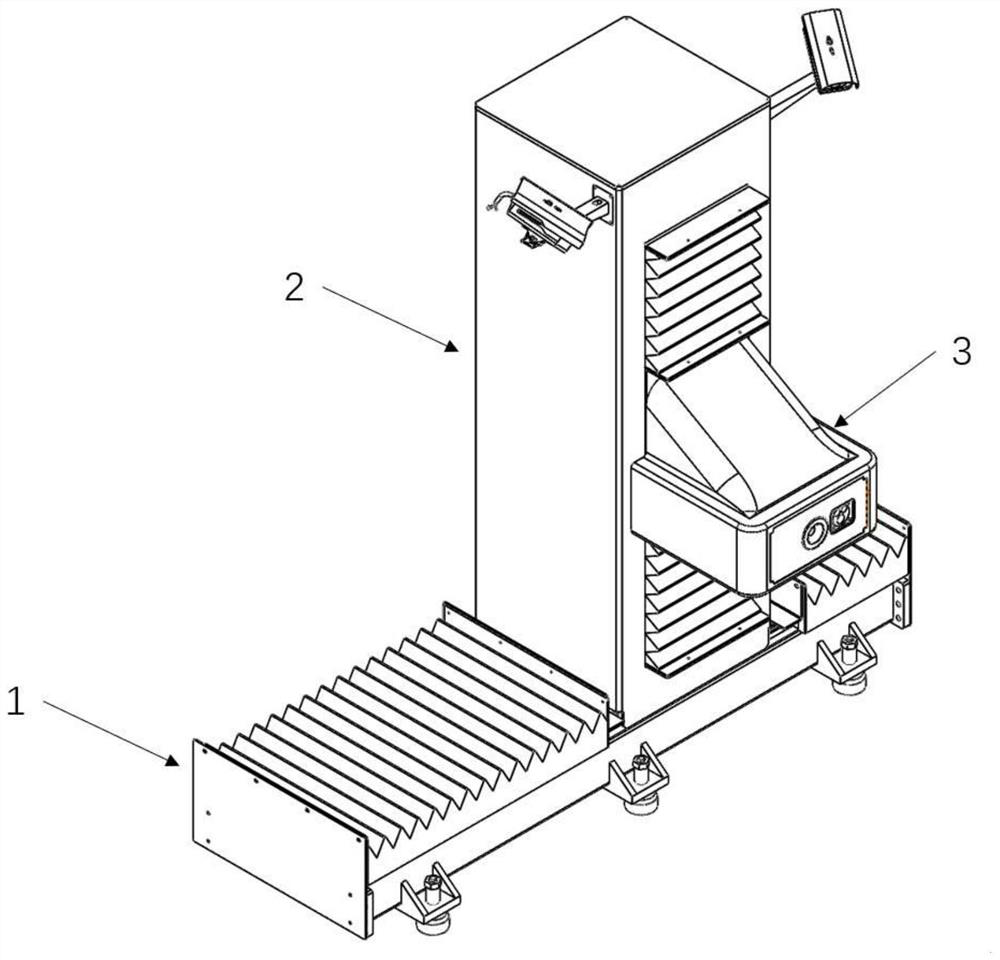

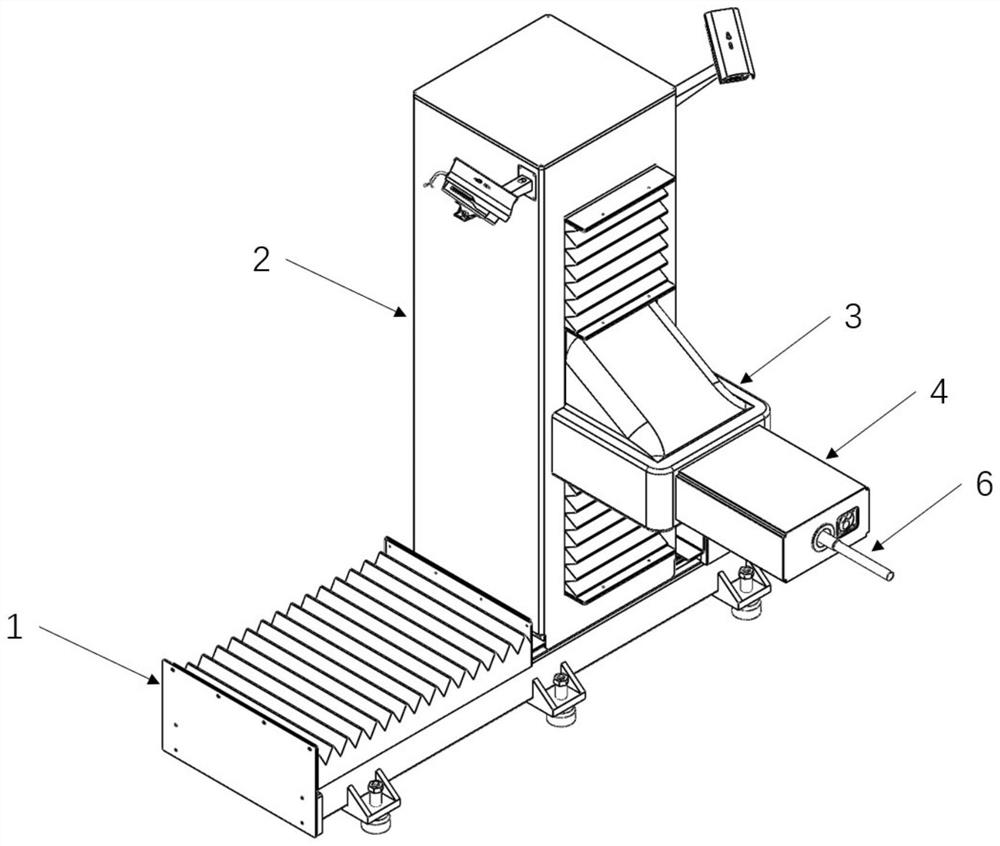

An automatic car refueling robot

A technology for robots and automobile fuel tanks, used in packaging, liquid distribution, conveying or transferring devices, transportation and packaging, etc., can solve the problems of nearby personnel injury, weak anti-destructive ability, gas station congestion, etc., to achieve pitch angle and heading. Angle, strong anti-destructive ability, simple trajectory planning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

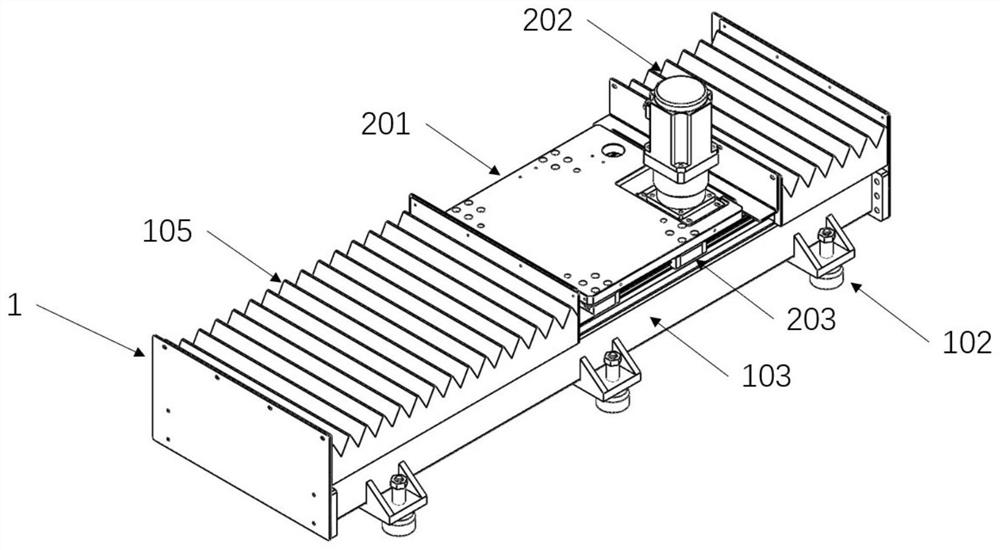

[0040] In an automatic vehicle refueling robot of the present invention, the left and right moving base 1 and the up and down moving base 2 are movably connected by the guide rail slider; the up and down moving base 2 and the first-level front and rear moving base are movably connected by the guide rail slider; The first-stage front-rear moving base and the second-stage front-rear moving base are movably connected by rail sliders; the second-stage front-rear moving base and the oil gun mouth are movably connected by automatic centering flexible oil gun clamps. The up and down moving base 2 is moved relative to the left and right moving base 1 through the rack and pinion motion driven by the motor; The moving base is moved relative to the first-stage forward and backward moving base through the motor-driven rack and pinion movement; the automatic centering flexible oil gun clamp is driven by the cylinder to move relative to the second-stage forward and backward moving base; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com