Special adjustable support for tooling steel plate forming of aviation composite material and forming method thereof

A technology of composite materials and steel plates, which is applied in the field of special adjustable supports for the forming of aviation composite tooling steel plates and its forming, which can solve problems such as high manufacturing costs, hidden fire safety hazards of wooden support tires, and reduce the forming accuracy of steel plates, so as to improve the forming Accuracy and production efficiency, solving the springback problem of steel plates, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

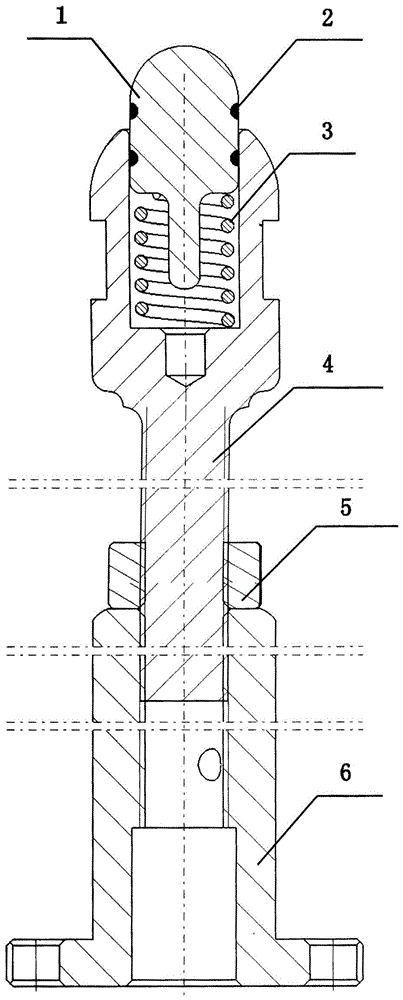

[0024] Such as figure 1 As shown, a special adjustable support for tooling steel plates made of aviation composite materials is used. The inner hole of the positioning support base 6 is threaded to connect the trapezoidal thread support 4, and the outer circumference of the trapezoidal thread support 4 is provided with a lock nut 5, which is locked The nut 5 is seated on the upper surface of the positioning support base 6; a spring 3 is provided in the cavity of the upper end of the trapezoidal thread support 4, and the ball push rod 1 is supported on the spring 3, and the outer circumference of the ball push rod 1 is provided with a self-lubricating The lead ring 2, the lower end of the ball push rod is provided with an extension rod 1-1 stretching into the spring; the upper end of the ball push rod 1 is a hemispherical surface, and the upper end of the trapezoidal thread support member 4 is also a hemispherical surface.

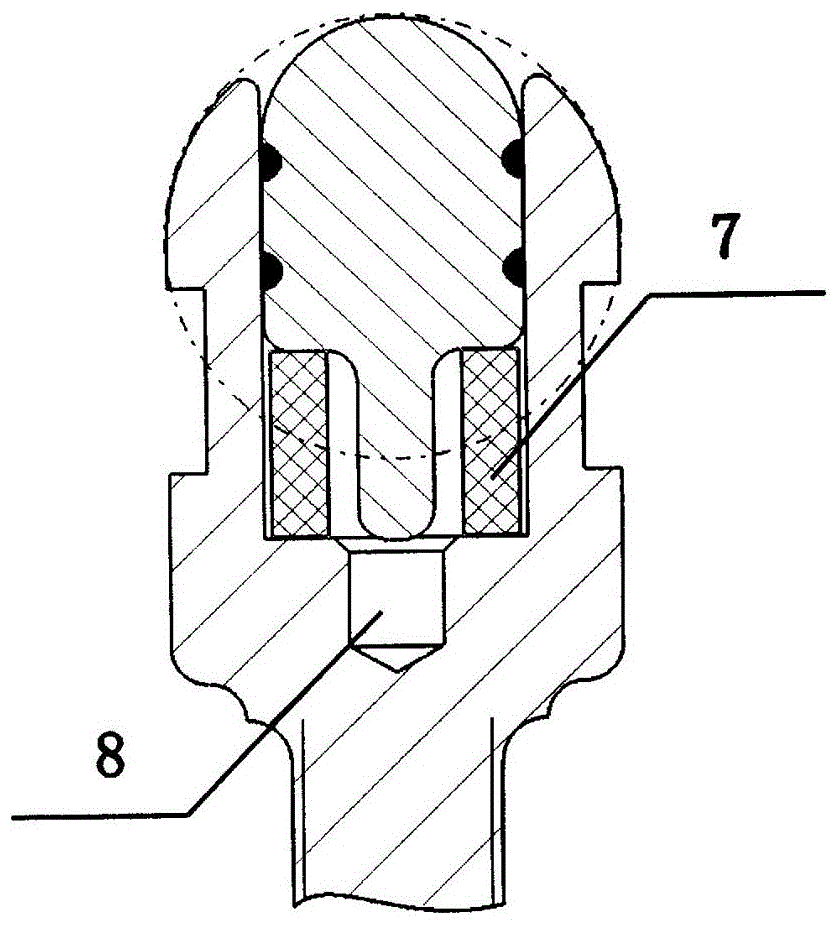

[0025] The bottom of the inner cavity of the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com