Torsion-resistant automobile axle and its processing method

A processing method and anti-torsion technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve problems such as poor anti-twist ability, and achieve the effects of good anti-twist ability, light weight, and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

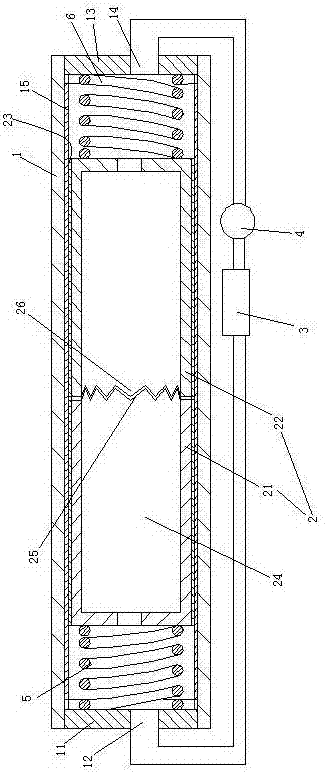

[0036] see figure 1 , a torsion-resistant automobile axle, including a rod-shaped main body 1 , an inner rod 2 , a thermostat 3 and a circulating pump 4 .

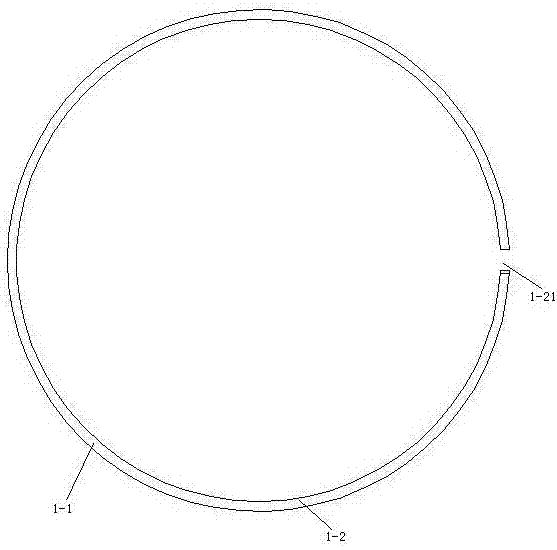

[0037] The rod-shaped main body 1 is a circular tube structure. A left plug 11 is sealingly connected to the left end of the rod-shaped main body 1 . The left plug 11 is provided with an abrasive agent inlet 12 . The right end of the rod-shaped main body 1 is sealingly connected with a right plug 13 . The right plug 13 is provided with an abrasive agent outlet 14 . The inner surface of the rod-shaped body 1 is provided with a second friction layer 15 . The second friction layer 15 is a circular tube structure.

[0038] The inner rod 2 is provided with a liquid flow channel 24 . The inner rod 2 includes a left rod 21 and a right rod 22 . The outer peripheral surfaces of the left rod 21 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com