Waterproof and twist-proof cables for wind power generation

An anti-twist and cable technology, which is applied in the direction of power cables, insulated cables, cables, etc., can solve the problems of poor waterproof and anti-twist performance, and achieve the effects of increasing insulation performance, improving anti-twist performance, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

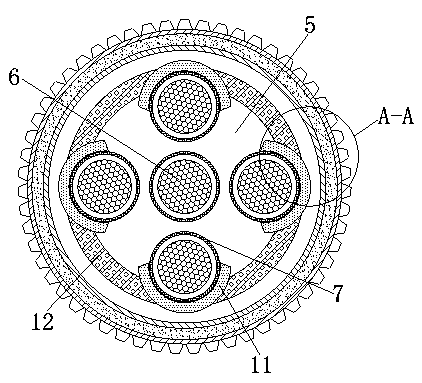

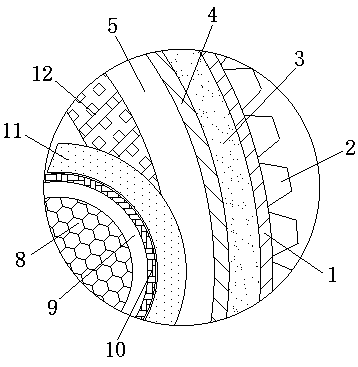

[0016] The first embodiment: please refer to Figure 1-2 , A waterproof and anti-twist cable for wind power generation, comprising an outer insulating layer 1, the thickness of the outer insulating layer 1 is 0.1-0.12mm, the surface of the outer insulating layer 1 is fixedly connected with rubber bumps 2, the number of rubber bumps 2 is No less than forty and equidistantly arranged on the surface of the outer insulating layer 1, the rubber bumps 2 can not only thicken the outer surface of the cable, but also effectively improve its anti-torsion degree and increase the insulation performance of the cable. An outer waterproof layer 3 is attached to the inner wall of the insulating layer 1, and a silica gel layer 4 is attached to the inner wall of the outer waterproof layer 3. The silica gel layer 4 has high corrosion resistance. When the wires and cables encounter corrosive liquids, they will Good protection effect, the thickness ratio between the outer insulating layer 1, the ou...

no. 2 approach

[0017] The second embodiment: a waterproof and anti-twist cable for wind power generation, comprising an outer insulating layer 1, the surface of the outer insulating layer 1 is fixedly connected with rubber bumps 2, the number of the rubber bumps 2 is multiple and equidistant It is arranged around the outer circumferential surface of the outer insulating layer 1. An outer waterproof layer 3 is attached to the inner wall of the outer insulating layer 1, and a silica gel layer 4 is attached to the inner wall of the outer waterproof layer 3. A filling layer 5 is attached to the inner wall, and a main wire 6 is arranged at the center of the filling layer 5, and secondary wires 7 are arranged inside the filling layer 5 and located on the top, bottom, and left and right sides of the main wire 6 , The four secondary wires 7 are arranged around the main wire 6 as the center. The main wire 6 and the secondary wires 7 each include a copper core 8 which is formed by twisting 23 wire bundl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com