A moving conductive rod, a moving end assembly and an arc extinguishing chamber using the moving conductive rod

A technology of moving conductive rods and components, applied in the fields of moving end components, moving conductive rods, and arc extinguishing chambers, can solve the problems of poor anti-twist performance, time-consuming and laborious thread connection process, and difficult wrench, etc., so as to improve the anti-twist performance, Easy to install, simple to assemble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

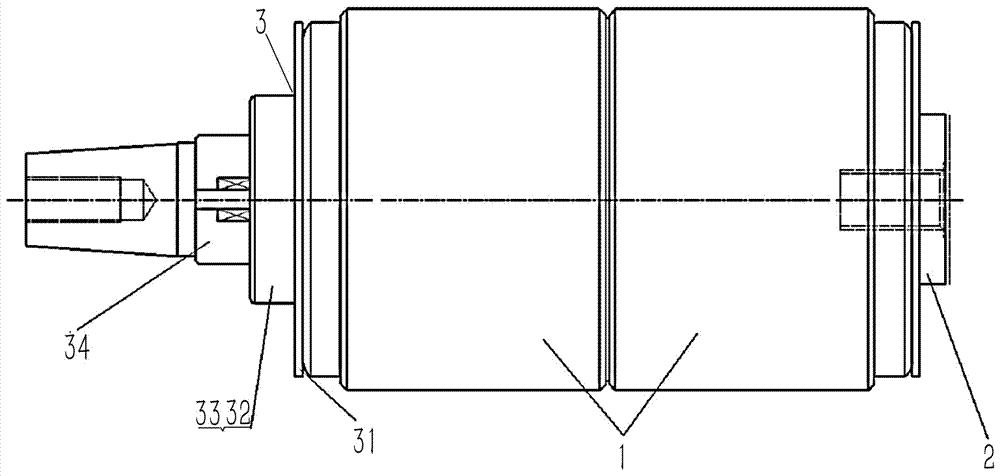

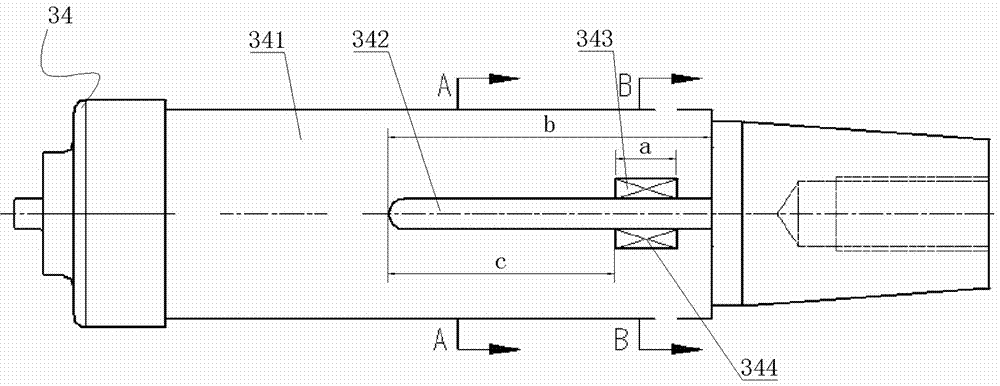

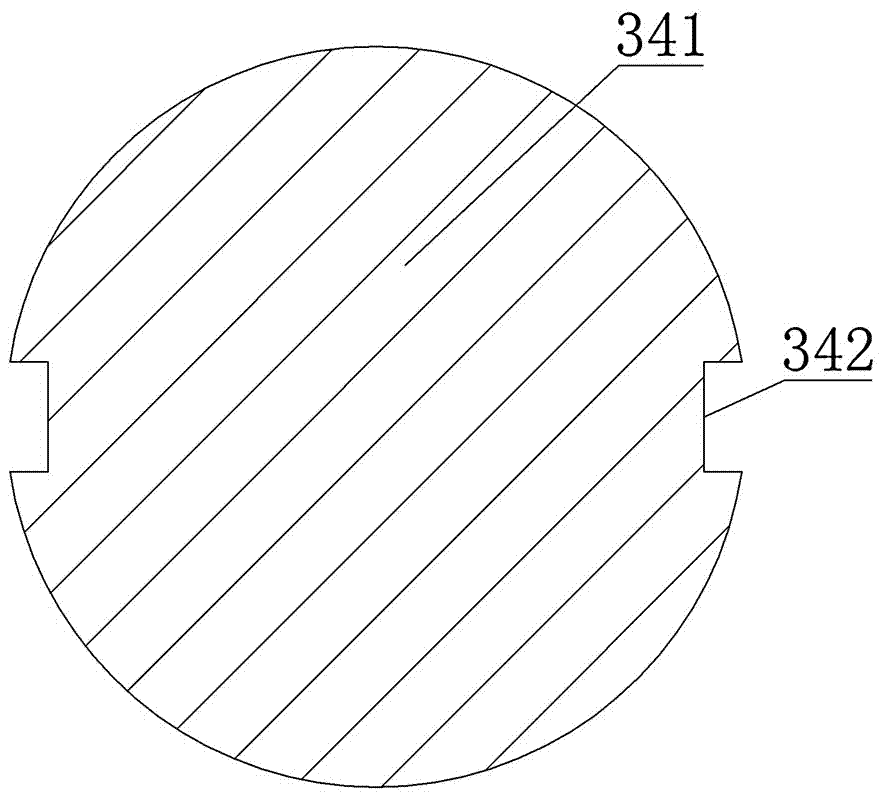

[0027] The embodiment of the arc extinguishing chamber in the present invention: as Figure 1 to Figure 7 As shown, the arc-extinguishing chamber is a vacuum arc-extinguishing chamber, which includes an outer casing 1, a movable end assembly 3 assembled at the inner movable end, and a static end assembly 2 assembled at the static end, wherein the outer casing 1 is a metallized porcelain shell, and the movable The end assembly 3 is mainly composed of a movable end cover plate 31 fixed on the movable end of the casing 1, a fixed flange 32 fixed on the movable end cover plate 31, and a guide sleeve 33 inserted into the inner hole of the movable end flange to prevent rotation. and the movable conductive rod 34 installed in the guide sleeve 33 to prevent rotation. The fixing flange 32 vacuum-brazes the guide sleeve 33 to the movable end cover plate 31 to fix it. The movable conductive rod 34 is a rod body extending back and forth. The front end of the rod body is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com