Welding-type jockey pulley base of stainless steel escalator step

An escalator, stainless steel technology, applied in the energy efficiency of escalators, escalators, sustainable buildings, etc., can solve the problems of difficult to guarantee product consistency, high rejection rate, energy consumption, etc., to improve product accuracy and consistency , The effect of improving production efficiency and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

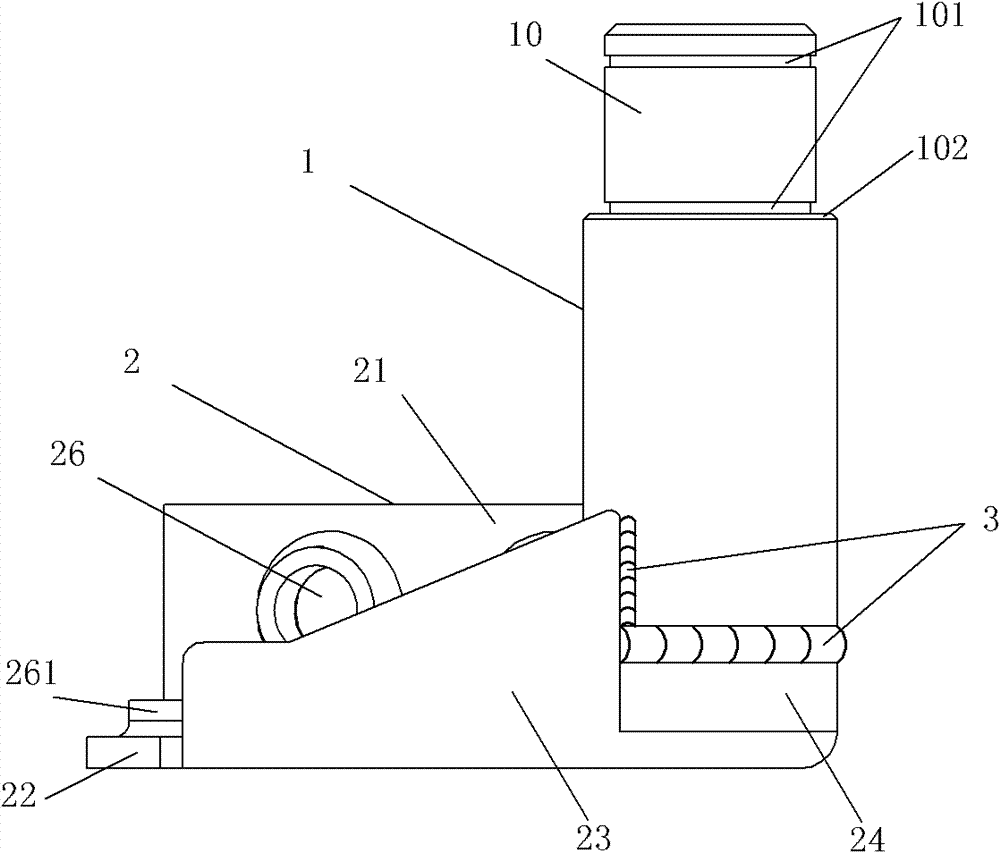

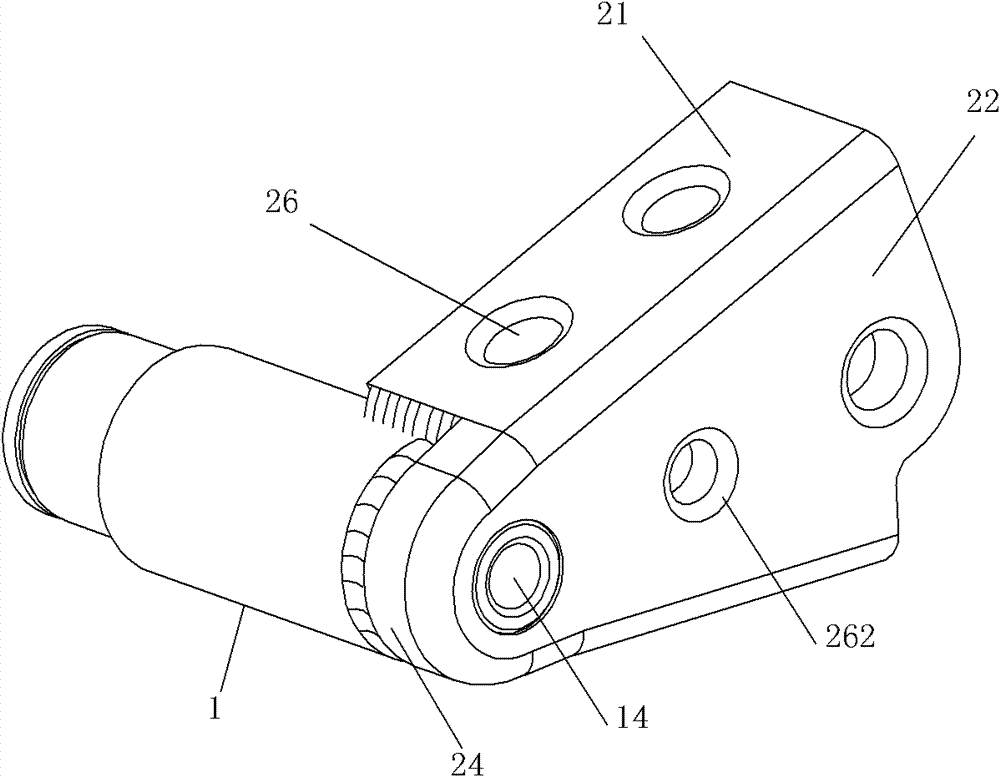

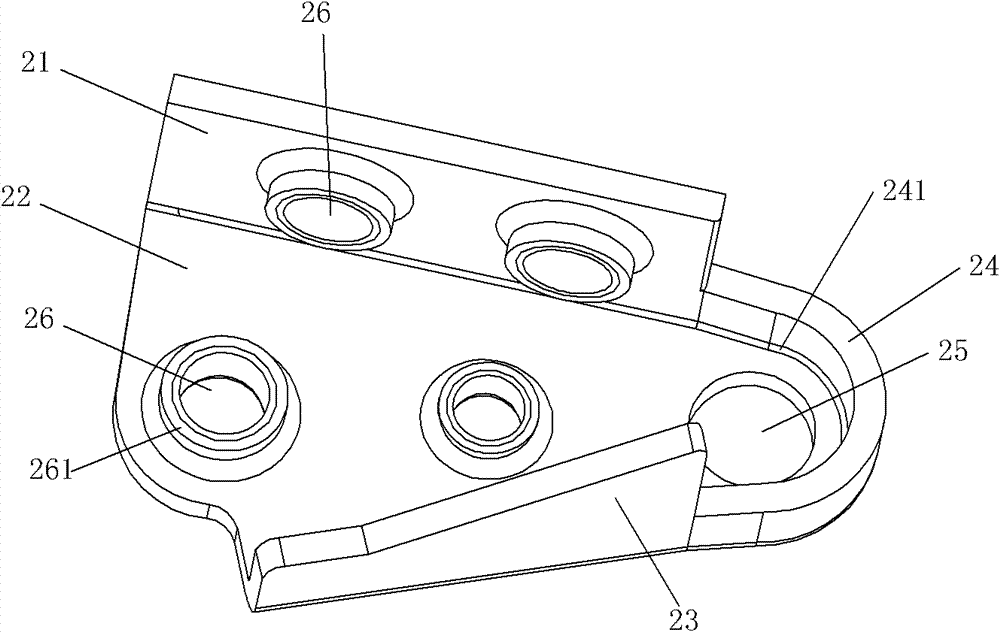

[0023] like Figure 1-3 As shown, the welded auxiliary wheel seat of the steps of the stainless steel escalator includes the auxiliary wheel shaft and the seat body 2 with the mounting hole 26. The auxiliary wheel shaft and the seat body are separate parts, and the two are welded and fixed; the auxiliary wheel shaft is cylindrical, including The upper auxiliary wheel mounting part 10, the middle shaft rod 1 and the lower shaft seat connecting end, the diameter of the auxiliary wheel mounting part is smaller than the shaft rod, and a limit step 102 is formed at the joint of the two, and the upper and lower ends of the auxiliary wheel mounting part are provided with There is a circumferential groove 101; the seat body is a plate stamping part, including a triangular bottom surface 22 and a side wall perpendicular to it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com