Tension adjusting, yarn chopping and linear speed measuring device of textile machinery

A tension adjustment, textile machinery technology, applied in the directions of transportation and packaging, conveying filamentous materials, thin material handling, etc., can solve the problems of inconvenient maintenance, troublesome installation, unable to meet the tension adjustment requirements of tension regulators, etc., and achieve convenient installation. and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

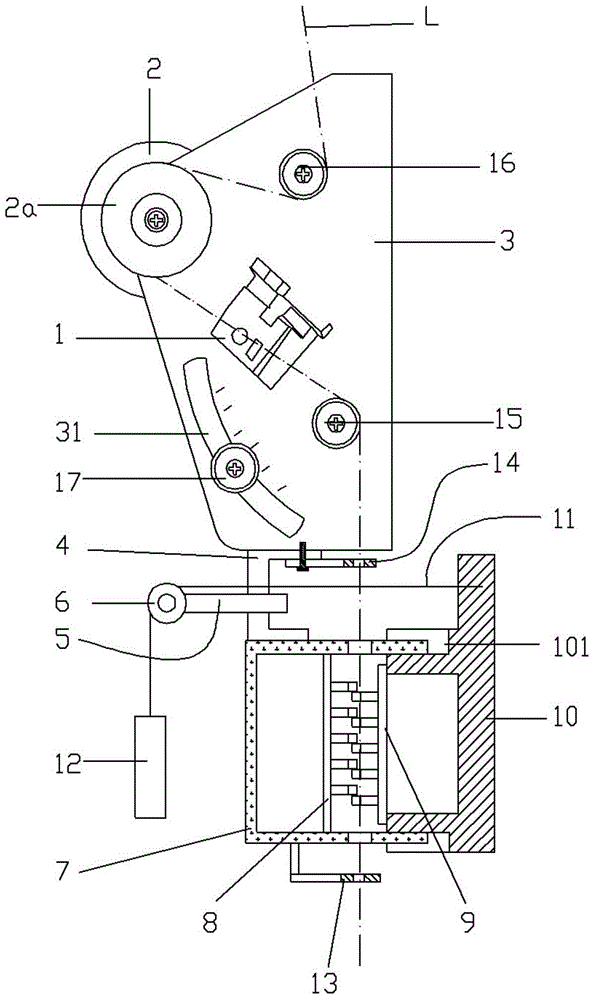

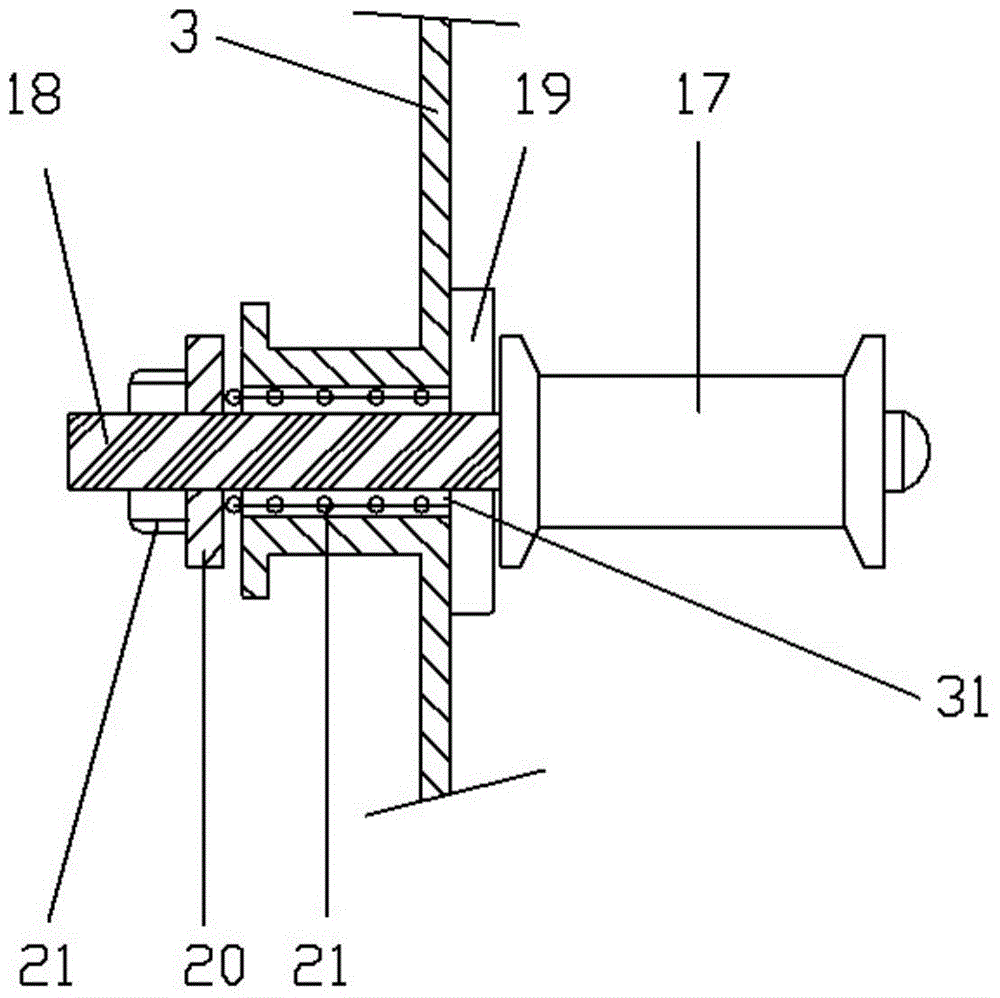

[0020] Example: see Figures 1 to 6 As shown, the textile machine tension adjustment yarn cutting linear speed measuring device includes a yarn cutter 1 and a linear speed sensor 2. The yarn cutter 1 and the linear speed sensor 2 are fixed on the box body 3, and the lower part of the box body 3 is fixed with a bracket 4. The support rod 5 is fixed on the support rod 5, the pulley 6 is installed on the support rod 5, the U-shaped plate 7 is fixed on the lower part of the support 4, the tension clamp 8 is fixed on the U-shaped plate 7, and the tension dynamic clamp 9 is fixed on the slide On the block 10, a slot 101 is formed on the slider 10, and the two sides of the U-shaped plate 7 are inserted into the slot 101;

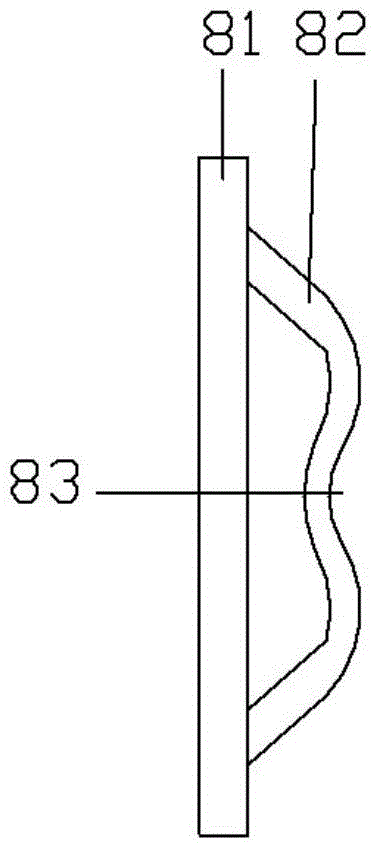

[0021] The structure of the tension clamp 8 is that several clamp blocks 82 are equidistantly formed on the clamp frame 81, and the middle part of the clamp block 82 is formed with a fixed clamp block arc groove 83; the structure of the tension movable clamp 9 A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com