Strong pull connection connector

A technology of connectors and rods, which is applied in the field of connection between prefabricated parts and strong tension connection connectors, can solve problems such as large gaps and slippage, reduce moving gaps, reduce connection gaps, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

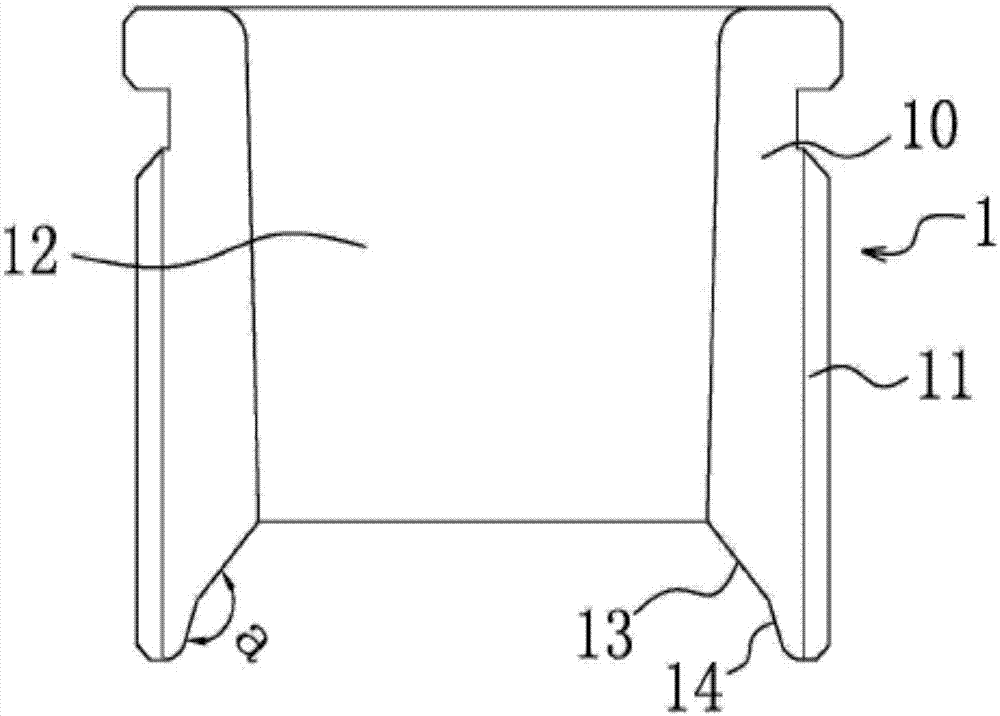

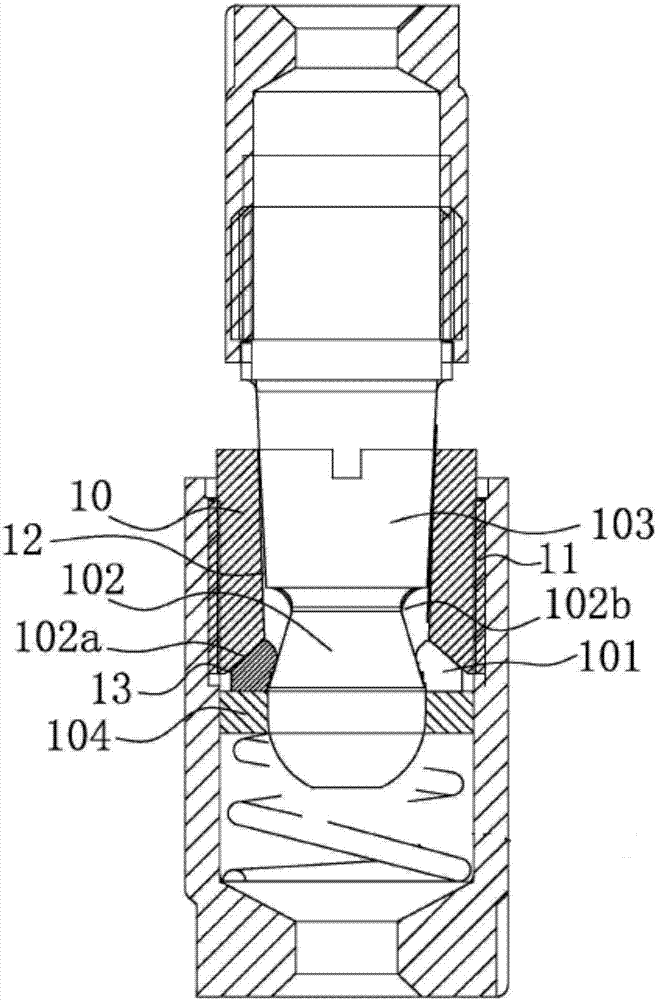

Examples

Embodiment 2

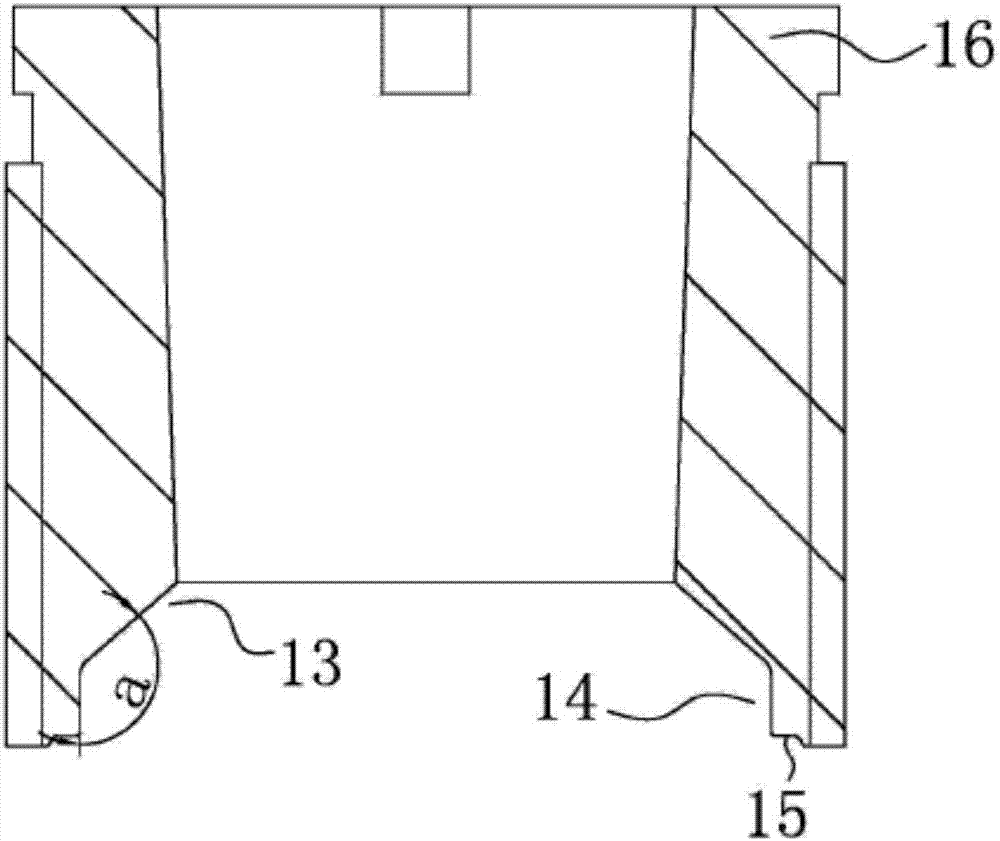

[0046] The structure and working principle of this embodiment are basically the same as that of Embodiment 1, the difference is that, as figure 2 As shown, the inner diameter of the channel 12 gradually decreases from the end away from the snap ring positioning cavity 13 to the end having the snap ring positioning cavity 13 . Therefore, the plug joint 102 of the insertion rod 103 can be close to the inner wall of the channel 12, and when the plug joint 102 is inserted to a certain depth, it can play a positioning role.

[0047] An end of the nut body 10 away from the snap ring positioning cavity 13 extends radially of the nut body 10 to form a nut limiting ring 16 . In this embodiment, the nut limiting ring 16 is circular. Of course, the nut limiting ring 16 can also be in other shapes, such as quadrangular, polygonal, elliptical and so on. When the intermediate nut 1 is completely screwed into the second tension nut 22, the nut stop ring 16 compresses the end of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com