Mud densimeter and fluid filling method for mud test

A mud density and density meter technology, which is applied to determine the specific gravity and other directions by measuring the pressure difference, can solve the problems of large volume, poor measurement accuracy, cumbersome structure, etc., and achieve the effects of reliable transportation, good sealing, and convenient installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

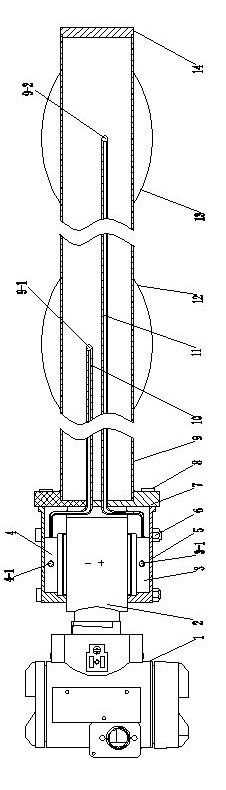

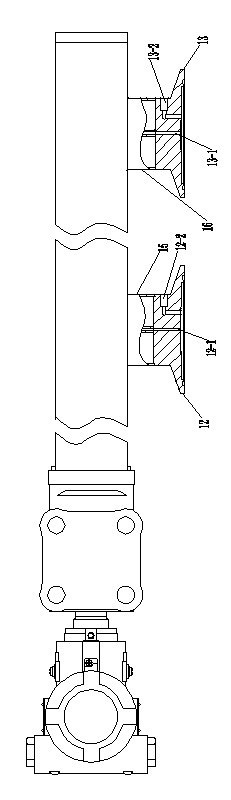

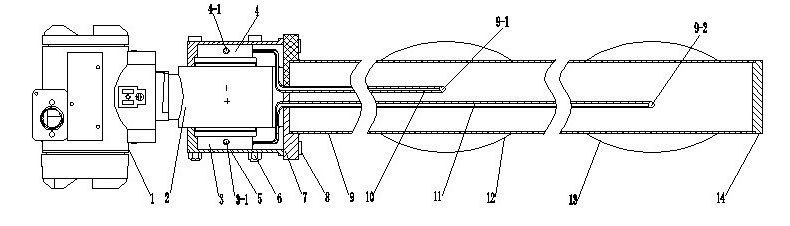

[0016] Such as figure 1 , 2 As shown, the mud density meter used for mud testing includes shell assembly 1, differential pressure sensor 2, positive connection seat 3, negative connection seat 4, capillary tube I10, capillary tube II11, membrane seat assembly I12, membrane seat assembly II13 , which is characterized in that: it also includes a chamber 5, a plate 7, a tube 9, a disc 14, a straight cylinder I15, and a straight cylinder II16, and the positive connection seat 3 and the negative connection seat 4 are respectively connected to the positive and negative sides of the differential pressure sensor 2. The tube 9 is welded together with the plate 7, the straight cylinder I15, the straight cylinder II16 and the disk 14 respectively, the membrane seat assembly I12 and the membrane seat assembly II13 are respectively welded on the straight cylinder I15 and the straight cylinder II16, and the capillary One end of Ⅰ10 and capillary Ⅱ11 passes through the holes Ⅰ9-1 and Ⅱ9-2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com