Method of preventing terminal of electric car controller from rotating, and anti-rotation terminal

A technology of electric vehicle controller and terminal, which is applied in the direction of clamping/spring connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

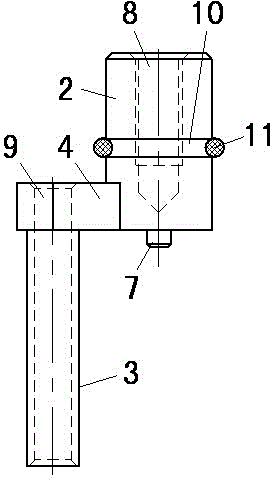

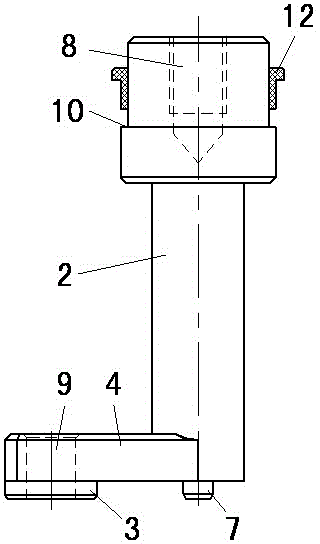

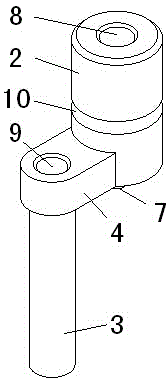

Method used

Image

Examples

Embodiment 1

[0044] Figures 15-17 It is a schematic diagram of the anti-rotation terminal of the present invention used in a 20kW electric vehicle DC brushless motor controller. In order to see the internal structure clearly, Figures 15-17 The casing cover is not drawn. in: Figure 15 It is a schematic diagram of the assembly of a 20kW electric vehicle DC brushless motor controller, which is composed of Figure 15 It can be seen that the power output module 13 in the figure is an integral power output integrated module, and the three power output modules are directly installed on the shell bottom plate 24 and connected by conductive strips. In this example, two upper and lower main control circuit boards are used. The anti-rotation terminal 1 is positioned on the lower main control circuit board. The bit hole is connected with the threaded hole on the power output module 13, or connected with the conductive bar connected with the power output module. The length of the power outp...

Embodiment 2

[0047] Figure 18-20 It is a schematic diagram of the anti-rotation terminal of the present invention being used for a 1500W electric tricycle and a DC brushless motor controller of a low-speed electric vehicle, wherein: Figure 18 It is a schematic diagram of the assembly of DC brushless motor controllers for 1500W electric tricycles and low-speed electric vehicles. Figure 18 It can be seen that the power output module 13 in the figure uses a power output circuit board composed of discrete components welded on the circuit board. In this example, two upper and lower main control circuit boards are used. The anti-rotation terminal 1 is positioned on the lower main control circuit board. The bit holes are connected with the threaded holes on the power output module 13 . The length of the power output module connecting post of the anti-rotation terminal 1 can be adjusted according to the actual situation. The high-current conductor connecting post of the anti-rotation ter...

Embodiment 3

[0050] Figures 21 to 23 The anti-rotation terminal of the present invention is used for a DC brushless motor controller for a 500W electric bicycle, wherein: Figure 18 It is a schematic diagram of the assembly of a brushless DC motor controller for a 500W electric bicycle, composed of Figure 21 It can be seen that the power output module 13 in the figure uses a power output circuit board composed of discrete components welded on the circuit board. The anti-rotation terminal 1 of the present invention is positioned on the main control circuit board 14, and the power output module connection column of the anti-rotation terminal 1 passes through the limit hole on the main control circuit board 14 and the screw thread on the power output module 13. hole connection. The length of the power output module connecting post of the anti-rotation terminal 1 can be adjusted according to the actual situation. The high-current conductor connecting post of the anti-rotation terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com