gear lever system

A shift lever and shift device technology, which is applied in the field of shift lever systems, can solve the problems of large space and occupancy, and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be described in detail with reference to the accompanying drawings, wherein the same reference numerals are used for the same or like parts throughout.

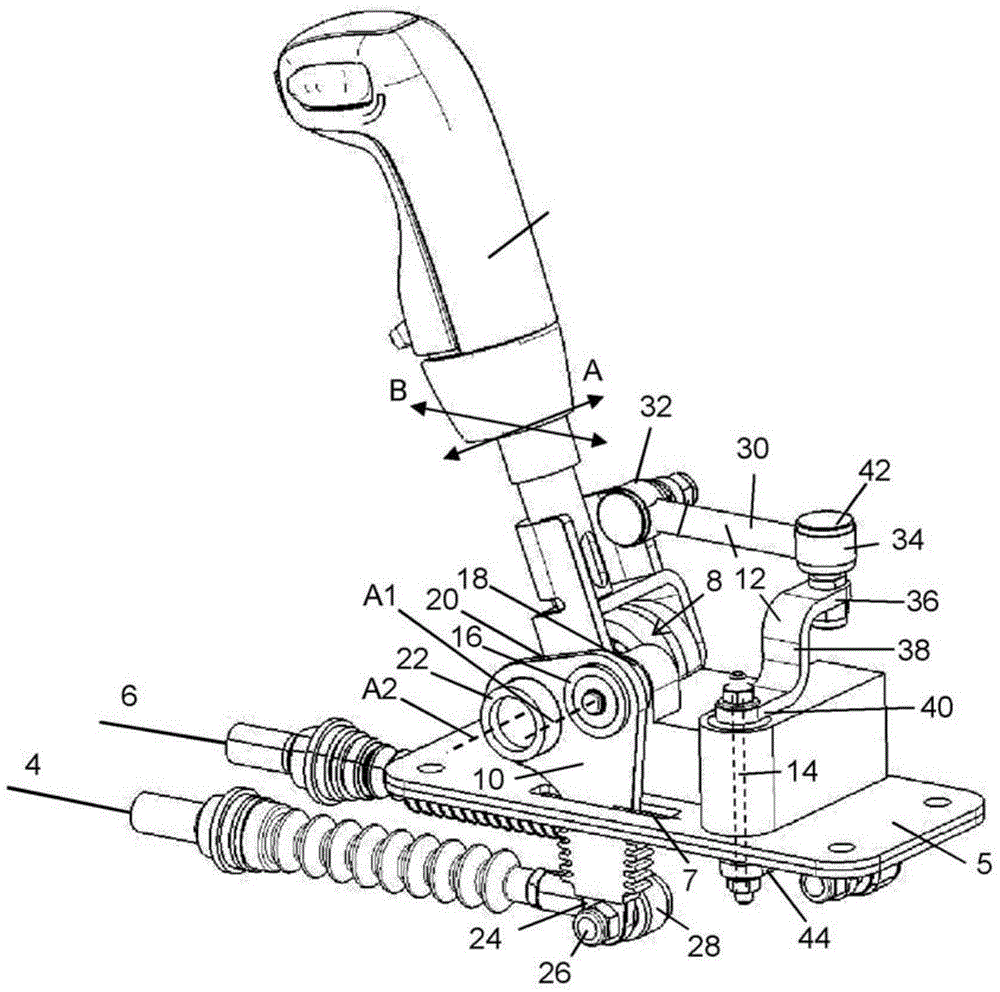

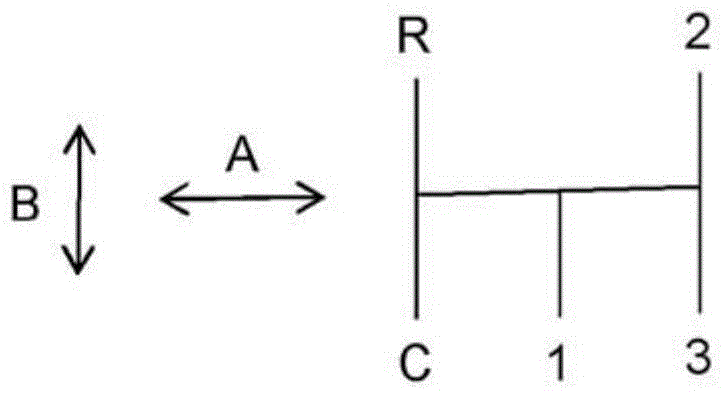

[0024] The present invention therefore relates to shift lever systems (see especially figure 1 , 4 and 5) which are used for shift-by-wire in a vehicle (preferably a truck), whereby the shift motion is transmitted from the shift lever 2 to the two shift wires 4, 6 which are transferred from the vehicle The location below the cab extends substantially horizontally and enters the vehicle gearbox. In the figures, the shift wire is arranged to extend through the corrugated boot.

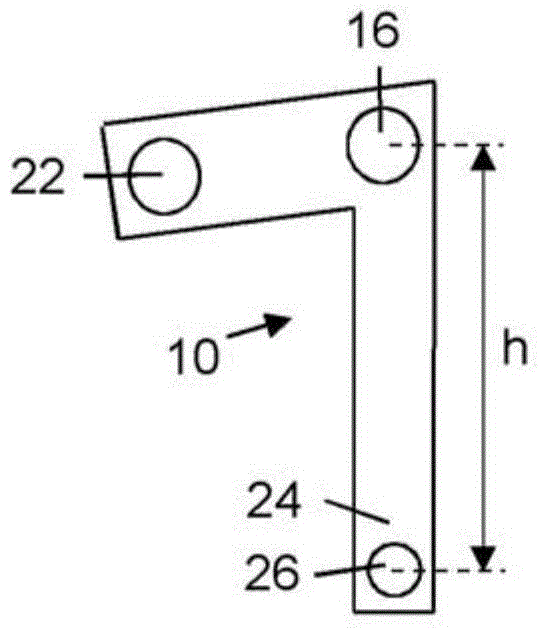

[0025] The selector lever system comprises a selector lever 2, a spherical bearing 8 with a point of rotation C, and a first transmission chain 10 and a second transmission chain 12 about which the selector lever can move, the first transmission The chain and the second drive chain are adapted to be subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com