Moving-out type self-lifting multi-layer negative-pressure plate making device

A technology of self-lifting and pressing boards, which is applied in lamination devices, lamination, lamination auxiliary operations, etc., to achieve the effect of avoiding unqualified products, stably lifting without swinging and not exceeding the travel distance, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

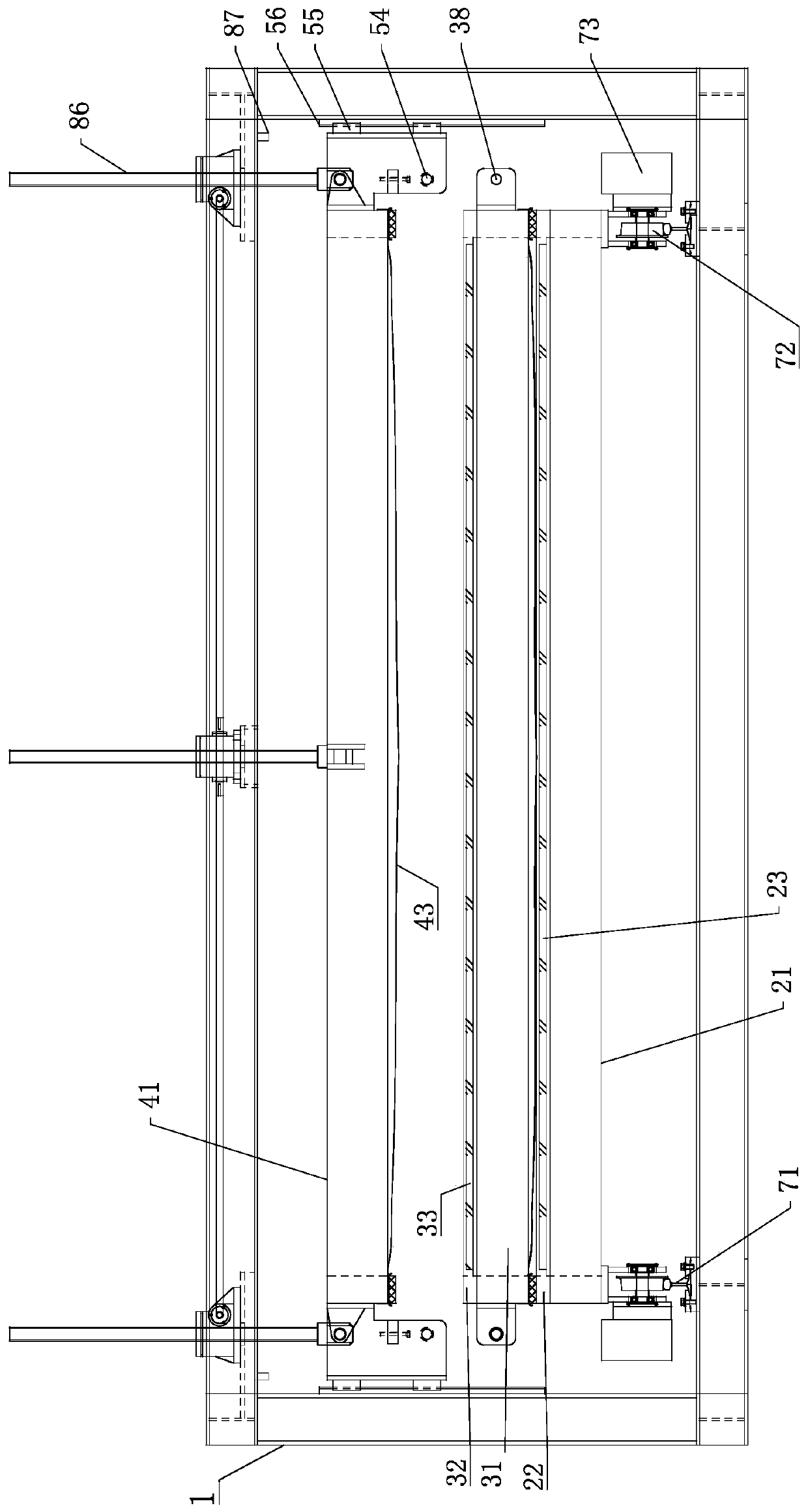

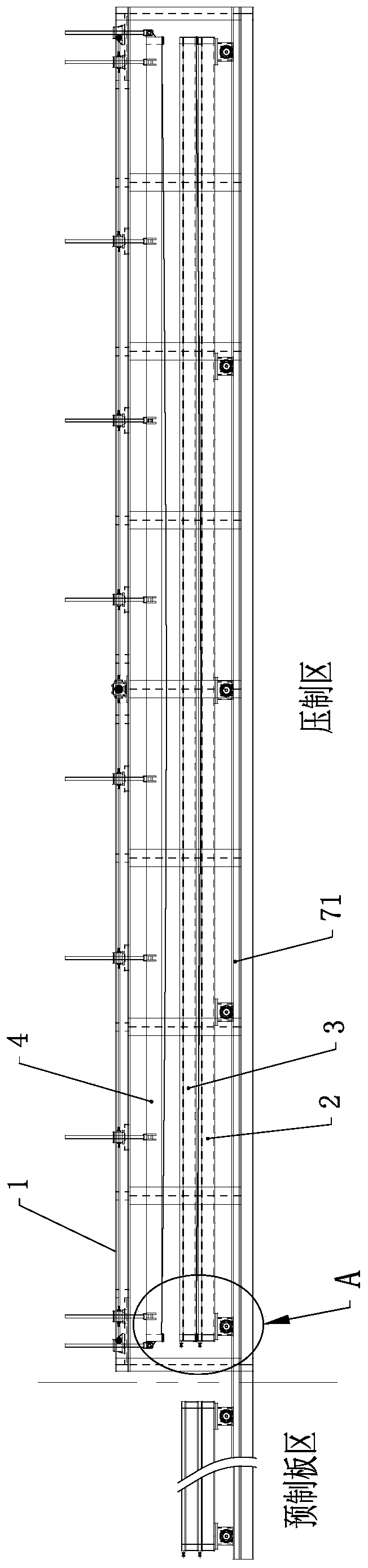

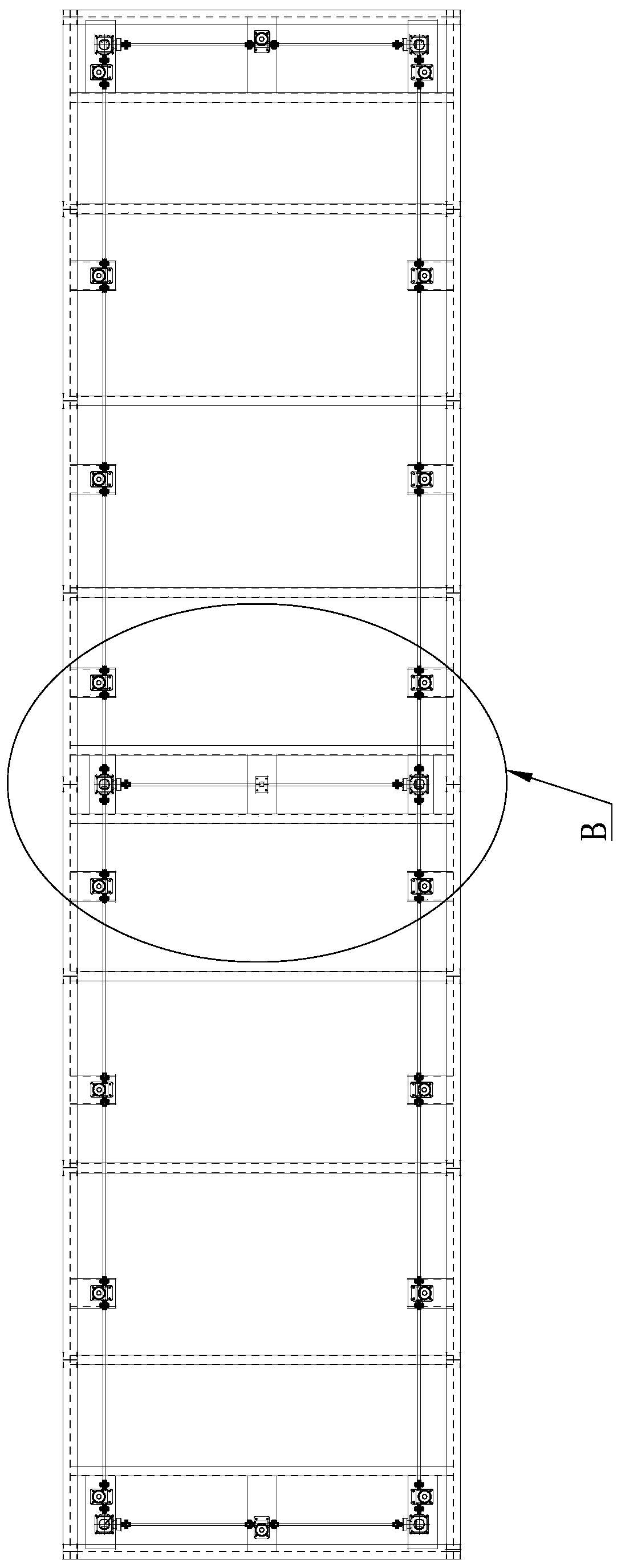

[0032] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0033] see Figure 1 to Figure 7 , a removable self-elevating multi-layer negative pressing plate device of the present invention includes a frame 1, a bottom mobile plate making platform 2, an upper layer plate making platform 3, a top layer integrated machine cover 4, and a top integrated machine cover that is installed on the top of the frame and drives the top layer. Lifting and positioning system for cover moving up and down. Frame 1 is set in the pressing area, and the frame is welded by national standard high-quality H-shaped steel to ensure that the overall level of the equipment and the structure are stable.

[0034] The bottom mobile board making platform 2 is moved and set on the frame 1 through the guide rail drive system so as to move back and forth between the pressing area and the prefabrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com