A kind of molding method of convenient two-layer food

A molding method, a convenient technology, applied in dough molding and cutting combination, food science, dough sheeting machine/rolling machine/rolling pin, etc., can solve unfavorable final molding effect, uneven support force, tilt, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] A molding method for convenient two-layer food, characterized in that: comprising the following steps:

[0135] In the first step, after the dough is pressed, it is cut into a plurality of elongated dough strips 6;

[0136] In the second step, raw or cooked fillings are transferred to the position of the noodle belt 6;

[0137] The third step is to feed the filling to one side of the dough. During the process of feeding the filling into the dough, the angle formed between the path of the filling and the plane where the dough is located is 45°-135°;

[0138] In the fourth step, the other side of the dough is first pushed into the forming hole 47 of the outer molding template 46 and the inner molding template 45, at this moment, the middle part of the dough wraps the filling to form a preliminary shape;

[0139] The fifth step is to seal and shape the dough wrapped with fillings, and at the same time, print and shape the dough of the sealed part.

[0140] The sixth step...

Embodiment 2

[0144] A molding method for convenient two-layer food, characterized in that: comprising the following steps:

[0145] In the first step, after the dough is pressed, it is cut into a plurality of elongated dough strips 6;

[0146] In the second step, raw or cooked fillings are transferred to the position of the noodle belt 6;

[0147] The third step is to feed the filling to one side of the dough. During the process of feeding the filling into the dough, the angle formed between the path of the filling and the plane where the dough is located is 45°-135°;

[0148] In the fourth step, the other side of the dough is first pushed into the forming hole 47 of the outer molding template 46 and the inner molding template 45, at this moment, the middle part of the dough wraps the filling to form a preliminary shape;

[0149] The fifth step is to seal and shape the dough wrapped with fillings, and at the same time, print and shape the dough of the sealed part.

[0150] The sixth step...

Embodiment 3

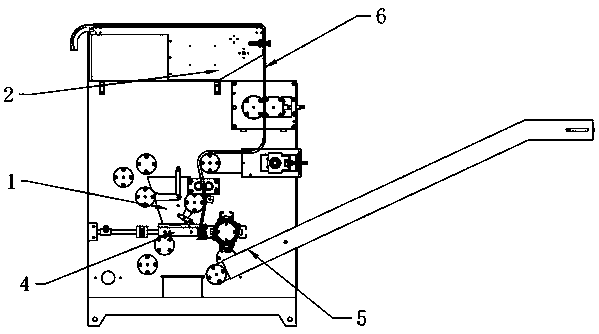

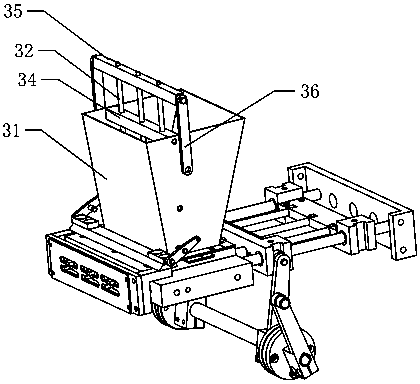

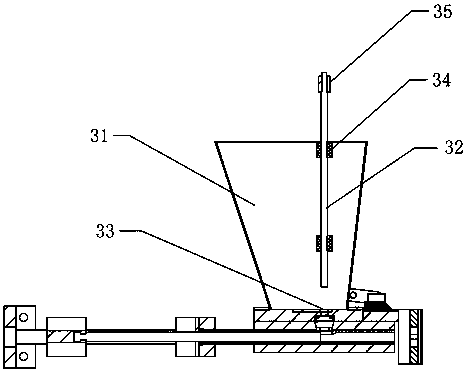

[0160] On the basis of Examples 1 and 2, the equipment used in the forming method is a convenient two-layer food forming machine, including a frame 1 and a noodle supply mechanism 2 arranged on the frame 1, a stuffing mechanism 3, and a stuffing forming machine. Mechanism 4 and clamping mechanism 5, described noodle supply mechanism 2 is positioned at the top of described stuffing mechanism 3, and described stuffing forming mechanism 4 is positioned at the below of described stuffing mechanism 3, and described stuffing forming mechanism 4 is positioned at one end The clamping mechanism 5 is provided; the component involved in the first step is the noodle supply mechanism 2, the component involved in the second step is the stuffing mechanism 3, and the component involved in the third and fourth steps is the stuffing forming mechanism 4. The component involved in the fifth step is the clamping mechanism 5 .

[0161] The stuffing forming mechanism 4 includes a feed pipe 41 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com