Natural silk bra taking silkworm cocoon shells as supporting lining

A silkworm cocoon shell and inner lining technology, applied in the field of silk brassiere, can solve the problems of compression resistance and connectivity to be improved, and achieve the effect of ensuring integrity, uniformity, and good arc transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

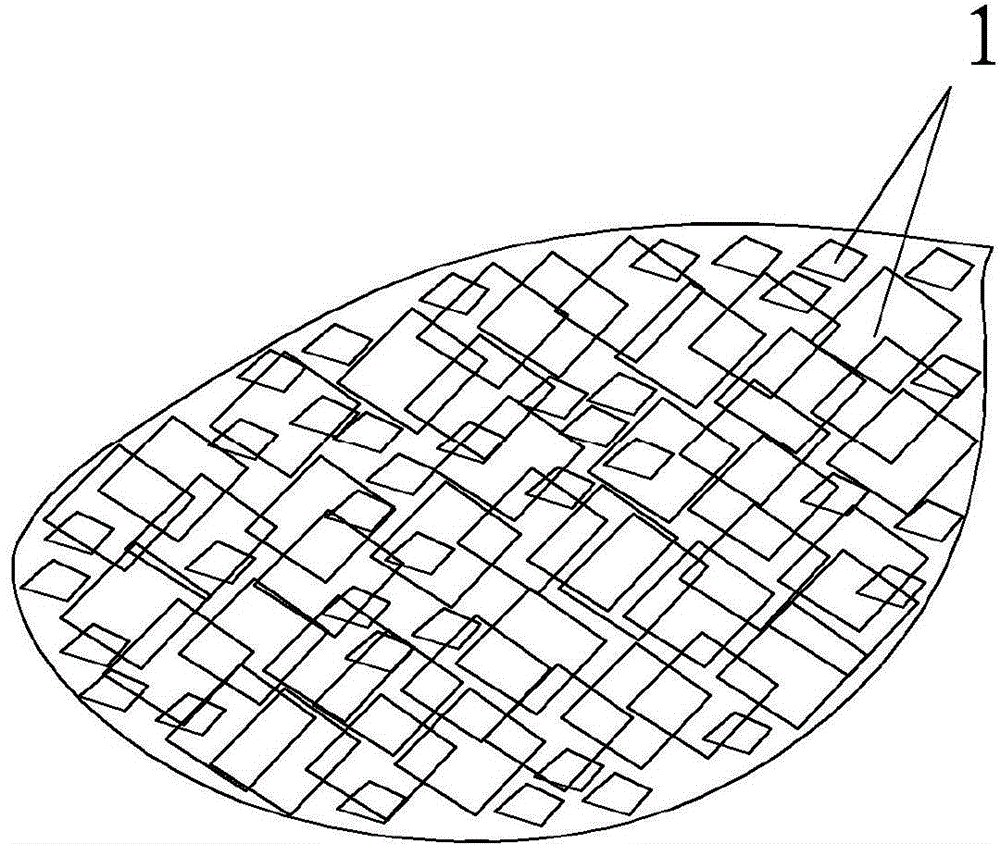

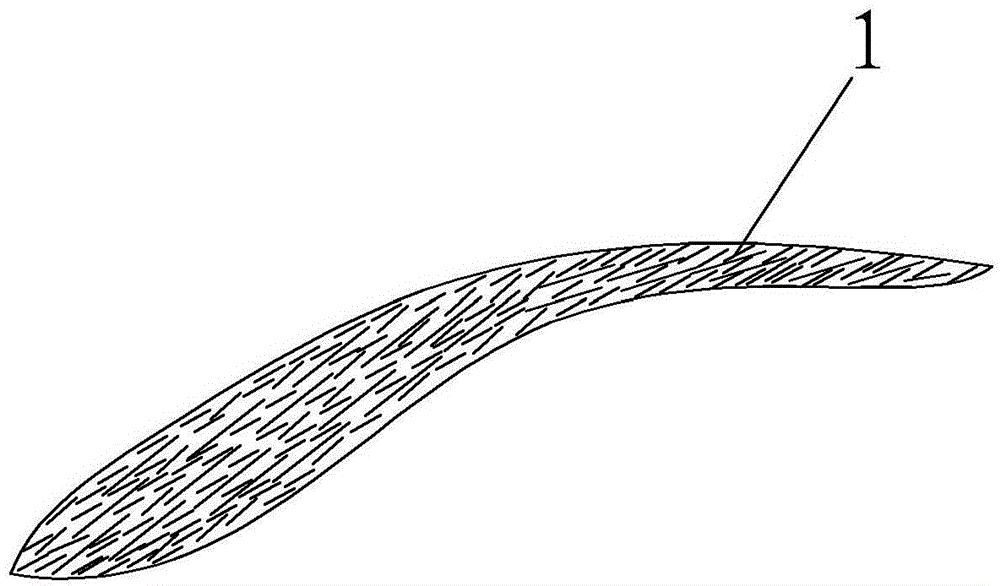

[0027] A silk bra with a cocoon shell as a support lining, which is composed of 100% silk, including a support lining and a silk fabric, wherein the support lining is made of diamond-shaped cocoon sheets with a side length of 0.4-1cm, and the diamond-shaped silk cocoon The sheets are bonded and solidified in the model to form a cup shape of a certain size and shape. The adhesion and curing process is as follows: the diamond-shaped cocoons are piled up in the cup model, and then subjected to temperature and humidity treatment at 34°C and 75% humidity for 30 minutes to make the diamond-shaped cocoon pieces adhere to form cocoon shell pieces. The surface of the cocoon shell sheet is covered with silk fabric, and then one cocoon shell sheet forms a supporting inner lining with a thickness of 1 cm and 5 g. The supporting inner lining is made detachable, and then fitted with the silk fabric and cut to obtain a silk bra.

Embodiment 2

[0029] A silk bra with a cocoon shell as a support lining, which is composed of 100% silk, including a support lining and a silk fabric, wherein the support lining is made of diamond-shaped cocoon sheets with a side length of 0.4-1cm, and the diamond-shaped silk cocoon The sheets are bonded and solidified in the model to form a cup shape of a certain size and shape. The adhesion and curing process is as follows: the diamond-shaped cocoons are piled up in the cup model, and then treated at 45°C and 90% humidity for 50 minutes to make the diamond-shaped cocoon pieces adhere to form cocoon shell pieces. The surface of the cocoon shell sheet is covered with silk fabric, and then three cocoon shell sheets form a supporting lining with a thickness of 3 cm and 12 g. The supporting inner lining is made into a non-detachable type, and then fitted and cut with the silk fabric to obtain a silk bra.

Embodiment 3

[0031] A silk bra with a cocoon shell as a support lining, which is composed of 100% silk, including a support lining and a silk fabric, wherein the support lining is made of diamond-shaped cocoon sheets with a side length of 0.4-1cm, and the diamond-shaped silk cocoon The sheets are bonded and solidified in the model to form a cup shape of a certain size and shape. The adhesion curing process is as follows: the diamond-shaped cocoons are piled up in the cup model, and then subjected to temperature and humidity treatment at 40° C. and a humidity of 85% for 40 minutes to make the diamond-shaped cocoon pieces adhere to form cocoon shell pieces. The surface of the cocoon shell sheet is covered with silk fabric, and then two cocoon shell sheets form a supporting inner lining with a thickness of 2 cm and 8 g. The supporting inner lining is made detachable, and then fitted with the silk fabric and cut to obtain a silk bra.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com