Method for processing biased barrel surface of piston ring

A processing method and piston ring technology, which is applied in metal processing equipment, manufacturing tools, honing machine tools, etc., can solve the problem that the sharp edges and corners of the piston ring cannot be maintained, the accuracy of the partial barrel surface is affected, and the sealing performance of the outer circular surface is not good. and other problems, to achieve the effect of improving the installed tensile cylinder and sealing performance, uniform color and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

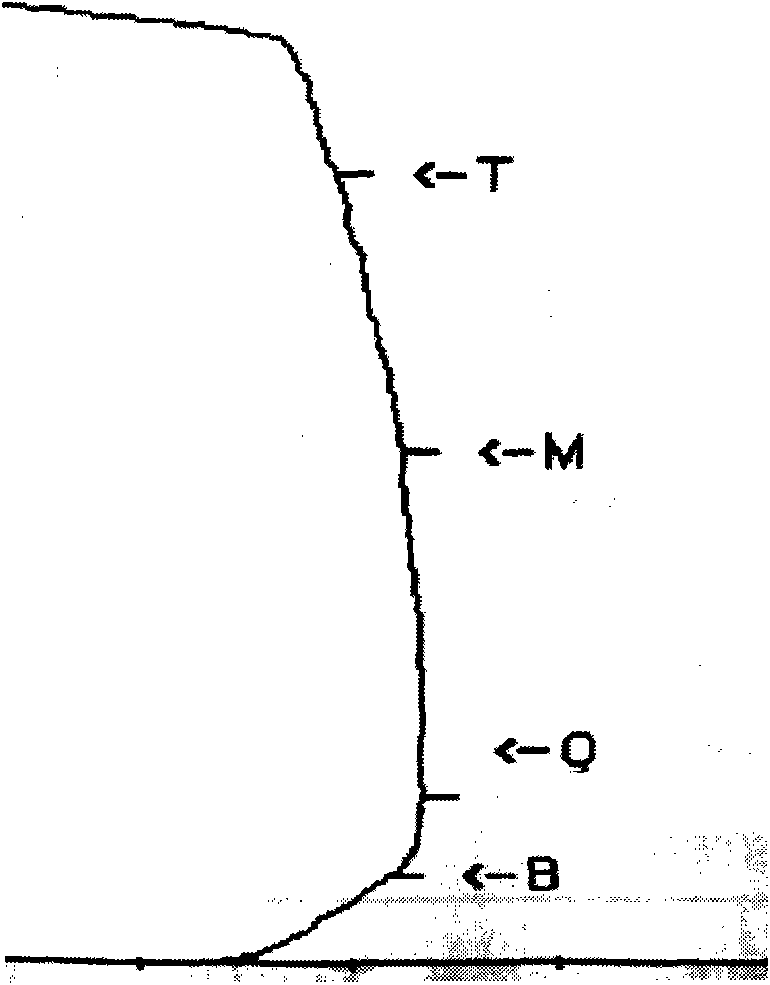

[0029] Taking the first ring (TOP) of Yuchai J6500 model as an example, it is required that the surface degree of the upper barrel surface at the position where the measured height is 2.4mm is: 0.013~0.028, such as Figure 5 shown.

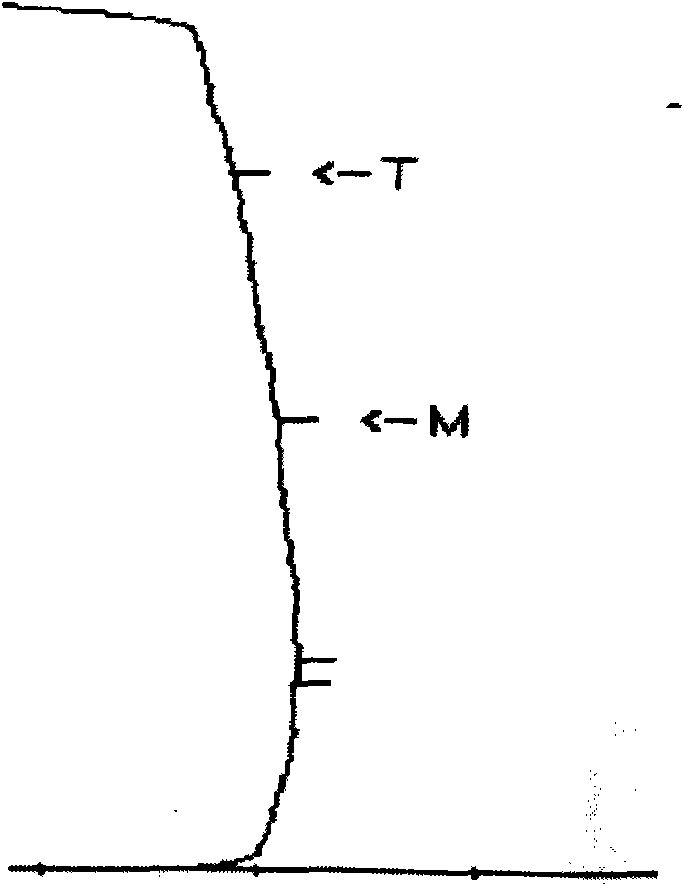

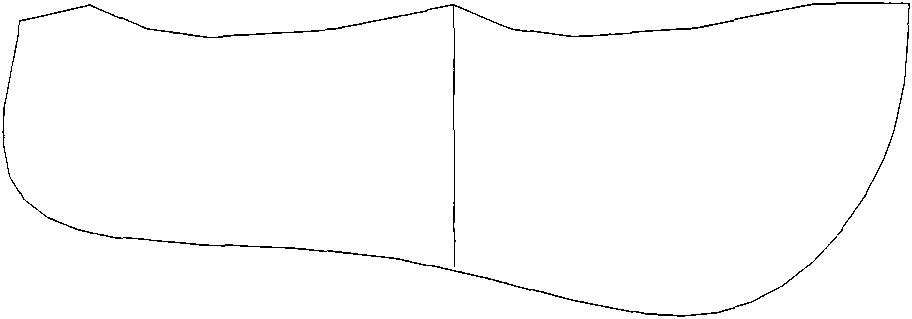

[0030] (1) Grinding the outer semi-circular arc surface: Grinding the outer surface of the piston ring into a semi-circular arc surface by using the forming mill and the template; the surface of the barrel at the ring height of 2.4mm by the template is taken as an intermediate value of 0.013 to 0.028 It is a bit larger, that is, 0.023mm, so the arc radius of the template is designed as R125.229, that is, Figure 6 shown.

[0031] (2) The semi-arc surface of the piston ring is finely honed to form the partial barrel surface by using the inclined pressure plate. Honing bar up and down speed: 8m / min; Turntable speed: 40r / min; Honing sleeve: 6-head single helix liner.

[0032] The honing fluid is formed by mixing grinding powder and machine oil, an...

Embodiment 2

[0034] Taking the first ring of Yangchai YZ4DA1 model as an example, it is required that the surface degree of the upper surface of the barrel at the position where the measured height is 2.3mm is: 0.018~0.034.

[0035] (1) Grinding the outer semi-circular arc surface. Grind the outer surface of the piston ring into a semi-circular arc surface by using a forming mill and a profiling template; the middle value of 0.018 to 0.034 is a little larger than the middle value of 0.018 to 0.034, which is 0.027mm. The arc radius of the formwork is designed to be R97.976.

[0036] (2) The semi-arc surface of the piston ring is finely honed to form the partial barrel surface by using the inclined pressure plate. Honing bar up and down speed: 8m / min; turntable speed: 30r / min; honing sleeve: 4-head single helix liner.

[0037] The honing fluid is formed by mixing grinding powder and machine oil, and the volume ratio of the grinding powder and machine oil is 1:10; the grinding powder is 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com