Novel pressing plate type hair cutter

A hair clipper and pressing plate technology, applied in the field of new clipping plate type hair clippers, can solve the problems of difficulty in meeting the requirement of uniform hair thickness, time-consuming and labor-intensive, etc., and achieve the effects of improving hair-cutting effect, reducing dependence and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

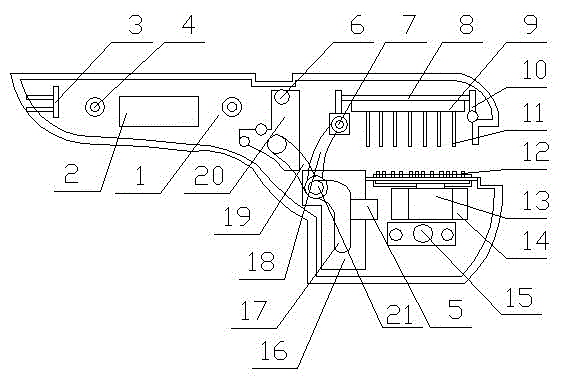

[0014] Such as figure 1 The new press-plate hair clipper shown includes a lower casing 1, a motor placement cavity 17 is arranged in the middle of the lower casing 1, a motor 12 is arranged inside the motor placement cavity 17, and a knife tooth support body 7 is connected to the motor 12. A plurality of knife teeth 6 are arranged on the upper part of the knife-tooth support body 7; the right side of the lower housing 1 is connected with a supporting housing 14, and the connection between the lower housing 1 and the supporting housing 14 is provided with an L-shaped movable groove body 16; A control switch 5 is arranged on the lower side of the middle part of the tank body 16; a rotating column 12 is arranged on the right end of the supporting housing 14, and an upper casing 4 is arranged on the rotating column 12; a plurality of springs 3 are arranged on the left side of the upper casing 4; The right side is provided with a spring connector 8, the upper end of the spring conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com