Fireproof curtain plate door structure

A curtain door and curtain board technology, which is applied to fire doors, door/window accessories, building structures, etc., can solve the problems of easy jamming, reduced smoothness, and the curtain board is not easy to coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

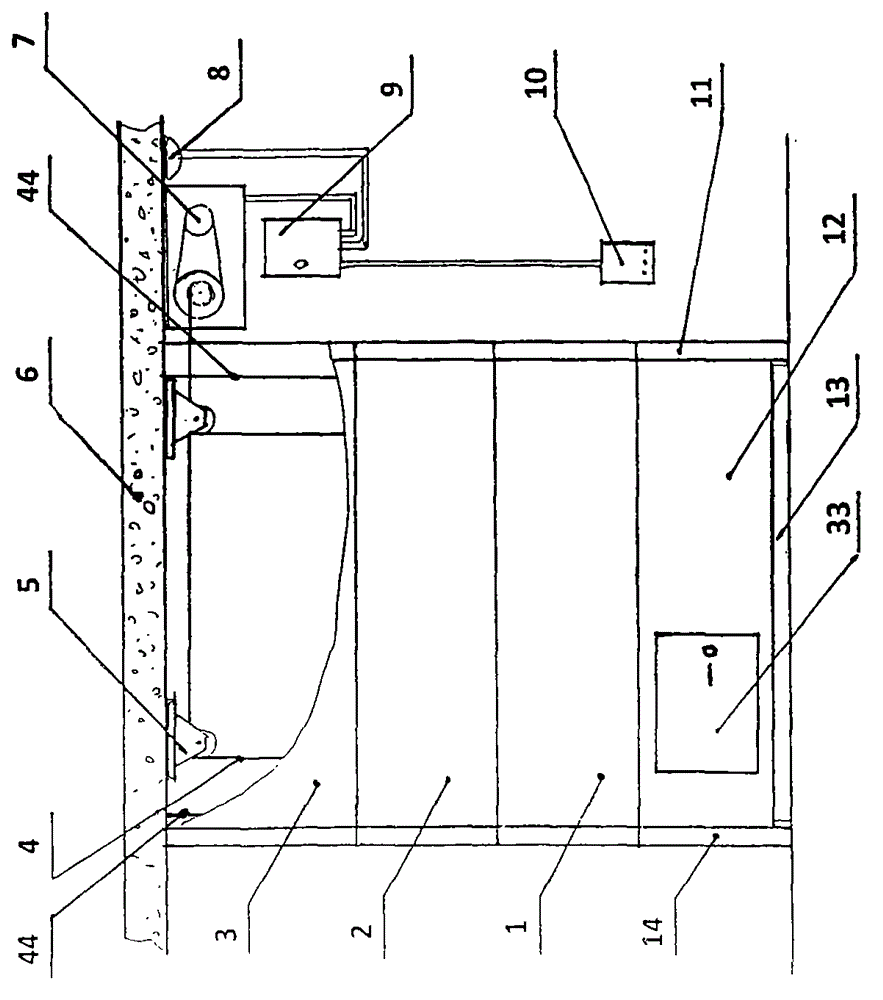

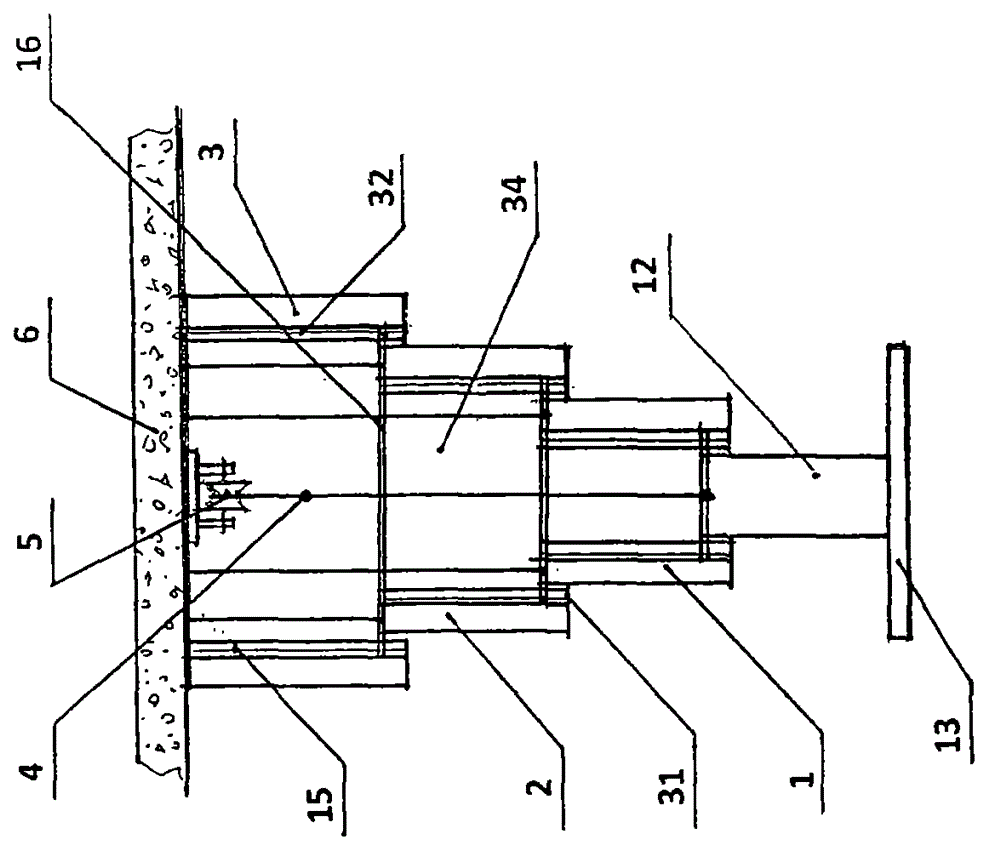

[0035] Example 1, in figure 1 In the structural schematic diagram shown, the present invention includes a main body of a fire curtain door and a driving part, and the main body of the fire curtain door is driven by the driving part, wherein the main body of the fire curtain door is composed of four curtain plates. Telescopic curtain door-shaped parts, the reciprocating sliding telescopic cooperation structure is formed between the adjacent curtain panels, and the driving part is a traction and pulling part with pull rope guide pulleys for driving the sliding of each curtain panel 4 , in addition, the present invention also includes a sliding limiting component that prevents each of the reciprocatingly slidable curtain panels from sliding out of adjacent curtain panels, and the sliding limiting component is arranged on each of the reciprocally slidable curtain panels. exist figure 1 with figure 2 In the schematic diagram shown, the main body of the above-mentioned fire curta...

Embodiment 2

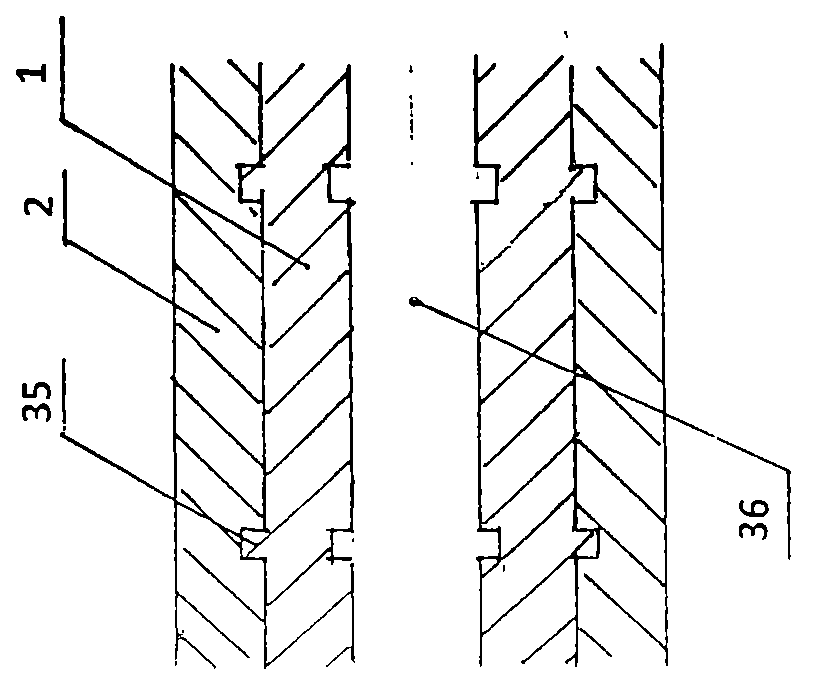

[0036] In Embodiment 2, the present invention has the same structure as that described in Embodiment 1 except that the sliding guide part adopted is changed. exist image 3 In the schematic diagram of the partial structure shown, four sliding grooves are provided on the main wall surface of the second hollow curtain 2 of the present invention, that is, the two inner wall surfaces, and the sliding groove 35 is one of them. Correspondingly, four sliding protrusions are provided on the first hollow curtain plate 1 to engage with the above-mentioned four chute slots and slide along the direction of the chute slots. The sliding groove and the sliding protrusion constitute the sliding guide part of the present invention, and the sliding guiding part can ensure smooth reciprocating sliding of each curtain plate. exist image 3 Among them, the hollow interlayer 36 of the first hollow curtain 1 can make the tail curtain of the present invention slide back and forth therein, forming a...

Embodiment 3

[0037] Embodiment 3, in addition to fixing the hollow curtain plate at the head end at the side frame of the building installation place, the present invention becomes a horizontally mounted fire curtain door that can reciprocate and slide horizontally and telescopically, and the drive components Except that the structure is changed, other structures are the same as those described in Example 1. exist Figure 4 The schematic diagram of the structure shown and Figure 5 In the top view structural schematic diagram shown, the head end hollow curtain plate 40 of the present invention is fixedly arranged at the side frame of the building fire door installation place, the hollow curtain plate 19, the hollow curtain plate 20, the head end hollow curtain plate 40 and the tail curtain plate 18 are all arranged between the curtain slide rail 41 at the bottom and the curtain slide rail 42 at the upper part, and the hollow curtain panel 19, the hollow curtain panel 20, and the tail curt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com