Pipeline insulation pipe sleeve

A technology for heat preservation pipe sleeves and pipe sleeves, which is applied in the direction of heat preservation, pipeline protection, pipes/pipe joints/pipe fittings, etc. It can solve the problems of large heat loss, energy consumption loss, and reduce the service life of pipes, so as to enhance the heat preservation effect and improve The effect of improving the service life and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 3-14 As shown, a pipeline insulation pipe sleeve includes a pipe sleeve body, an insulation layer is provided on the inner wall of the pipe sleeve body, and the pipe sleeve body is mainly formed by splicing two half-shells 1, and the two half-shells 1 The splicing surface is provided with a waterproof structure. The waterproof structure includes two pairs of press buckle groups fitted together. Each press block group includes a radial press buckle 11 and a radial buckle groove 12, and a radial press buckle 11 and a corresponding diameter The buckle grooves 12 are embedded together, the radial buckle 11 is arranged on the splicing surface of one of the half shells 1, and the corresponding radial buckle groove 12 is arranged on the splicing surface of the other half shell 1.

[0032] Such as Figure 13 As shown, the pipeline insulation pipe sleeve also includes a connecting knot 2, which is mainly formed by splicing two half knots. The end of the connecting kn...

Embodiment 2

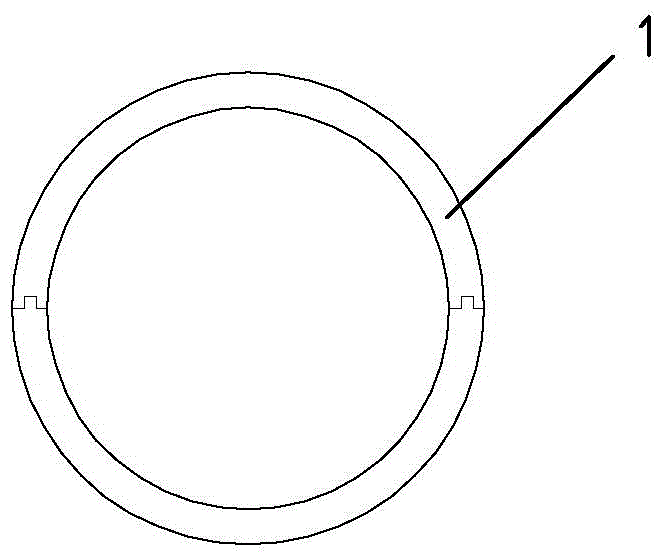

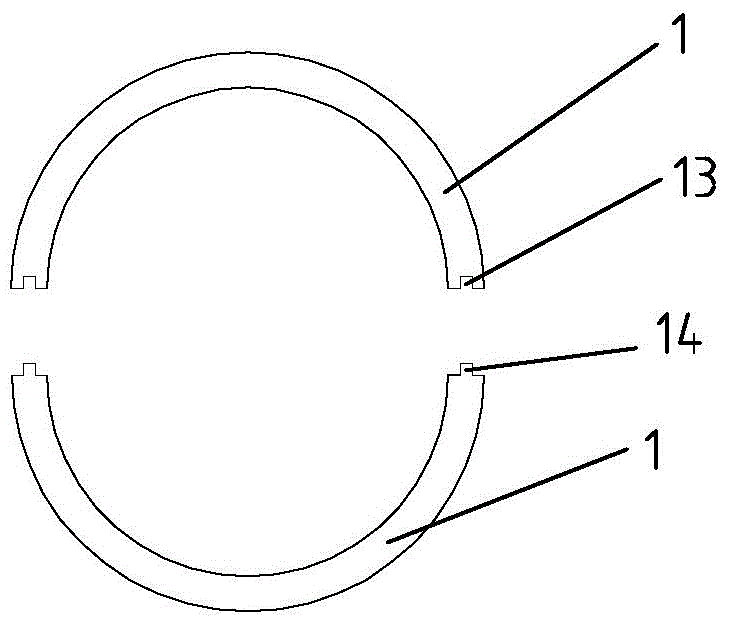

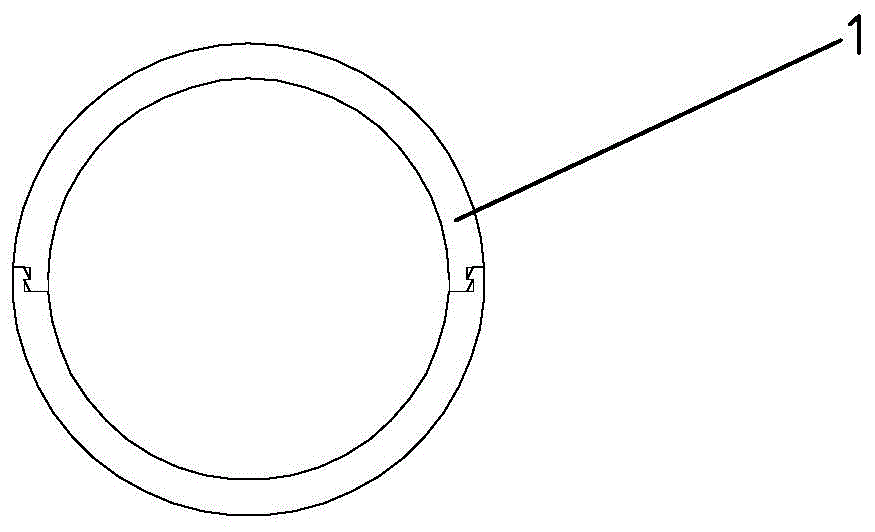

[0038] Such as figure 1 , 2 As shown, a pipeline insulation pipe sleeve includes a pipe sleeve body, an insulation layer is provided on the inner wall of the pipe sleeve body, and the pipe sleeve body is mainly formed by splicing two half-shells 1, and the two half-shells 1 A waterproof structure is provided at the splicing surface. The waterproof structure includes a circumferential waterproof groove 13 and a circumferential waterproof rib 14 that fit together. The circumferential waterproof groove 13 and the corresponding circumferential waterproof rib 14 are embedded together , The circumferential waterproof groove is arranged on the splicing surface of one of the half shells 1, and the corresponding circumferential waterproof rib 14 is arranged on the splicing surface of the other half shell 1.

[0039] The working principle of the present invention is as follows:

[0040] The present invention is provided with a waterproof structure on the two splicing surfaces between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com