Self-pumped water-turbine generator set bearing oil mist absorption device

A technology of hydroelectric generators and generator sets, which is applied in the fields of hydroelectric power generation, engine components, machines/engines, etc., and can solve problems such as energy consumption, high cost, and unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

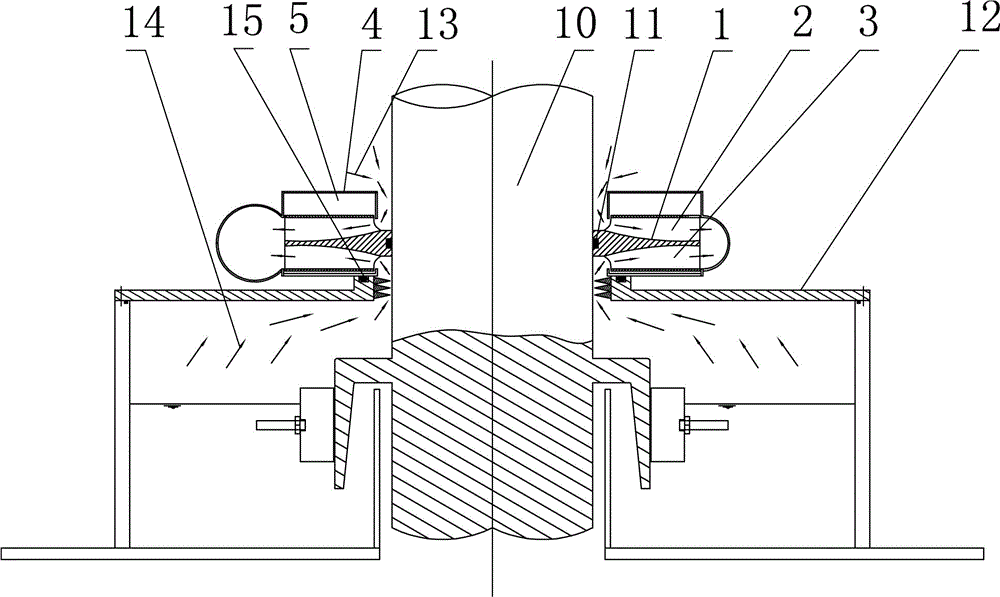

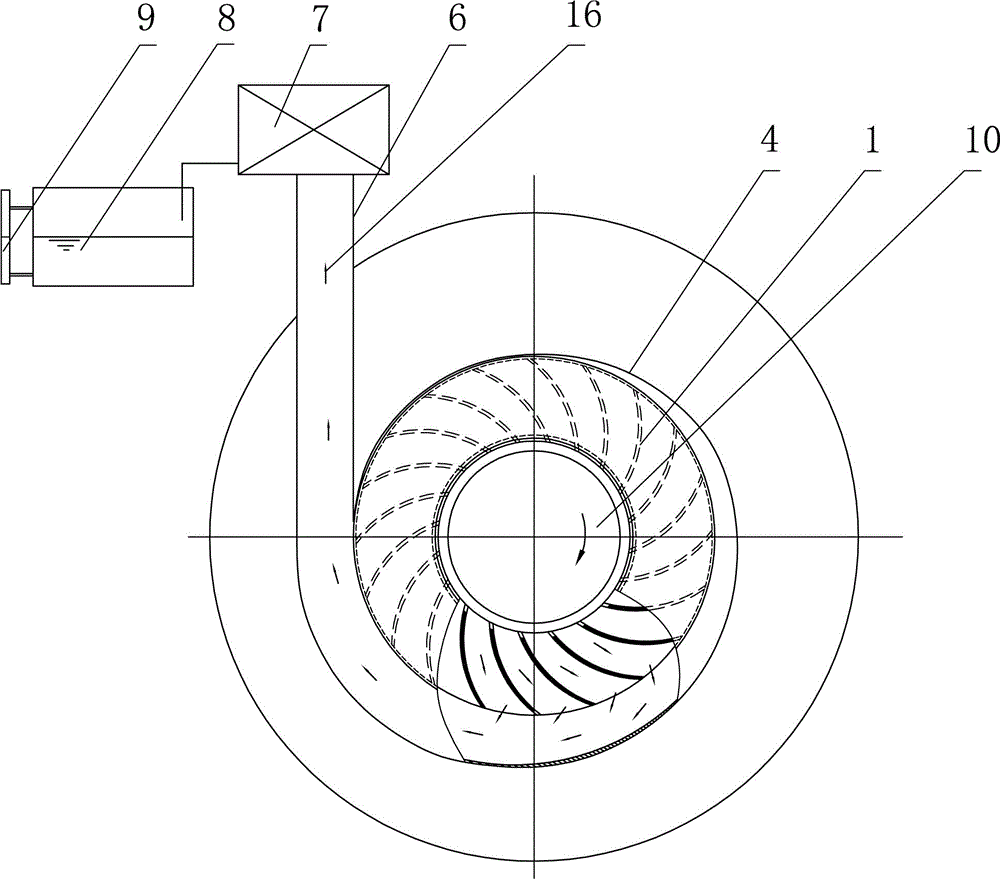

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as Figure 1-2 As shown, a self-pumped hydro-generator bearing oil mist absorbing device includes a hydro-generator shaft 10 on which an impeller 1 is fixed, thereby ensuring that the impeller 1 can follow The main shaft 10 of the hydro-generator rotates together to provide driving force for the rotation of the impeller 1; an oil-resistant rubber sealing ring 11 is arranged between the impeller 1 and the main shaft 10 of the hydro-generator to prevent oil mist in the bearing of the hydro-generator 14 Overflow from the gap between the impeller 1 and the large shaft 10 of the hydro-generator; the impeller 1 is divided into upper and lower parts that are not connected by the radial rotation surface of the impeller, and radial blades are provided to form the upper vane area 2 and the lower vane area respectively 3. The blades in the upper impell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com