Power cable connecting terminal combined member

A technology for connecting terminals and power cables, which is applied in the field of power cable connection terminal assemblies, can solve problems affecting power supply reliability, production and life, and cumbersome procedures, and achieve safe and fast assembly mobility, high social and economic benefits, and high operating technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

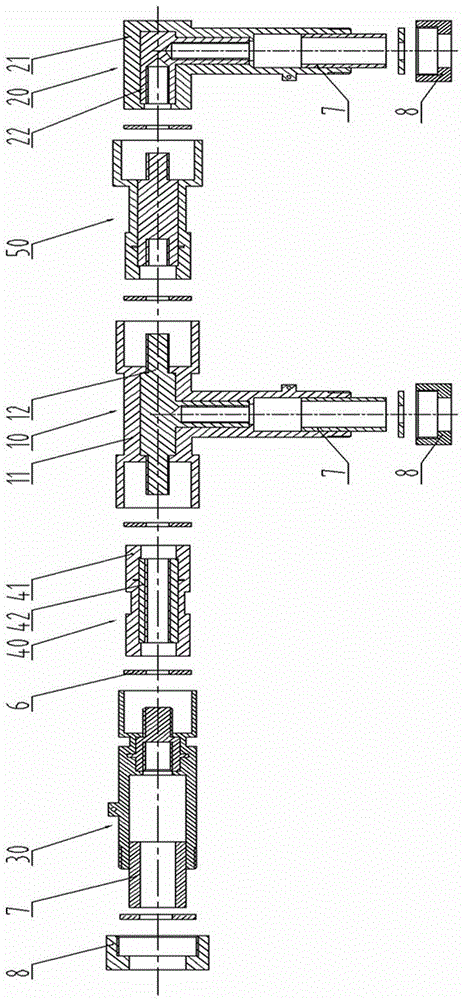

[0021] Preferred embodiment one, such as figure 1 As shown, this embodiment discloses a power cable connection terminal assembly, including a type I T-type connection terminal 10, a type I L-type connection terminal 20, a type I linear connection terminal 30, a type I butt joint 40, a type II Butt joint 50, rubber pad 6. Type I T-shaped connecting terminal 10, Type I L-shaped connecting terminal 20, Type I straight connecting terminal 30, Type I butt joint 40 and Type II butt joint 50 are all integral parts of inner conductor and outer hard insulating sleeve. The conductor insulation is enclosed in a hard insulating sleeve, and the connection ends of the internal conductors are all threaded.

[0022] Type I T-shaped connecting terminal 10 includes a T-shaped hard insulating sleeve 11 and a T-shaped inner conductor 12 embedded in its axial center. Threaded connection hole, the length of the three directions of the T-shaped hard insulating sleeve 11 is greater than the corresp...

Embodiment 2

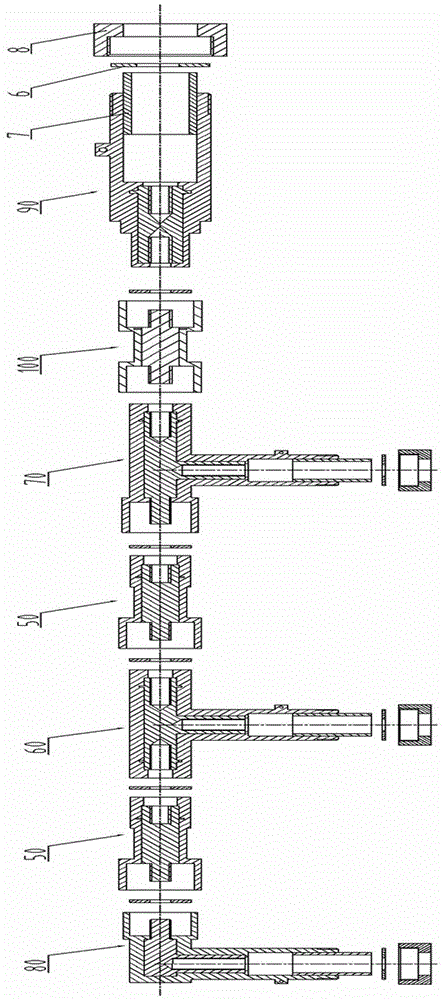

[0032] Preferred embodiment 2. The difference between this embodiment and preferred embodiment 1 is that this embodiment includes a Type II T-shaped connecting terminal 60 and a Type III T-shaped connecting terminal 70, a Type II L-shaped connecting terminal 80 and a Type II T-shaped connecting terminal. One straight connecting terminal 90 , two type II butt joints 50 and one type III butt joint 100 . The connection structure of the two connection ends of the T-shaped internal conductor head of the type II T-shaped connection terminal 60 is an internal thread hole, and the connection structure of the two connection ends of the T-shaped internal conductor head of the type III T-shaped connection terminal 70 is an external thread head, Internally threaded hole at the other end; Type II L-type connecting terminal 80 internal connecting conductor horizontal connection end is an external thread head; Type II straight connecting terminal 90 internally connecting conductor both ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com