Front-piercing cable connection device

A technology for connecting devices and cables, applied in the parts, connections, coupling devices and other directions of connecting devices, can solve the problems of a large number of garbage and harmful gases, high personnel requirements, low construction efficiency, etc. Low requirements and good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

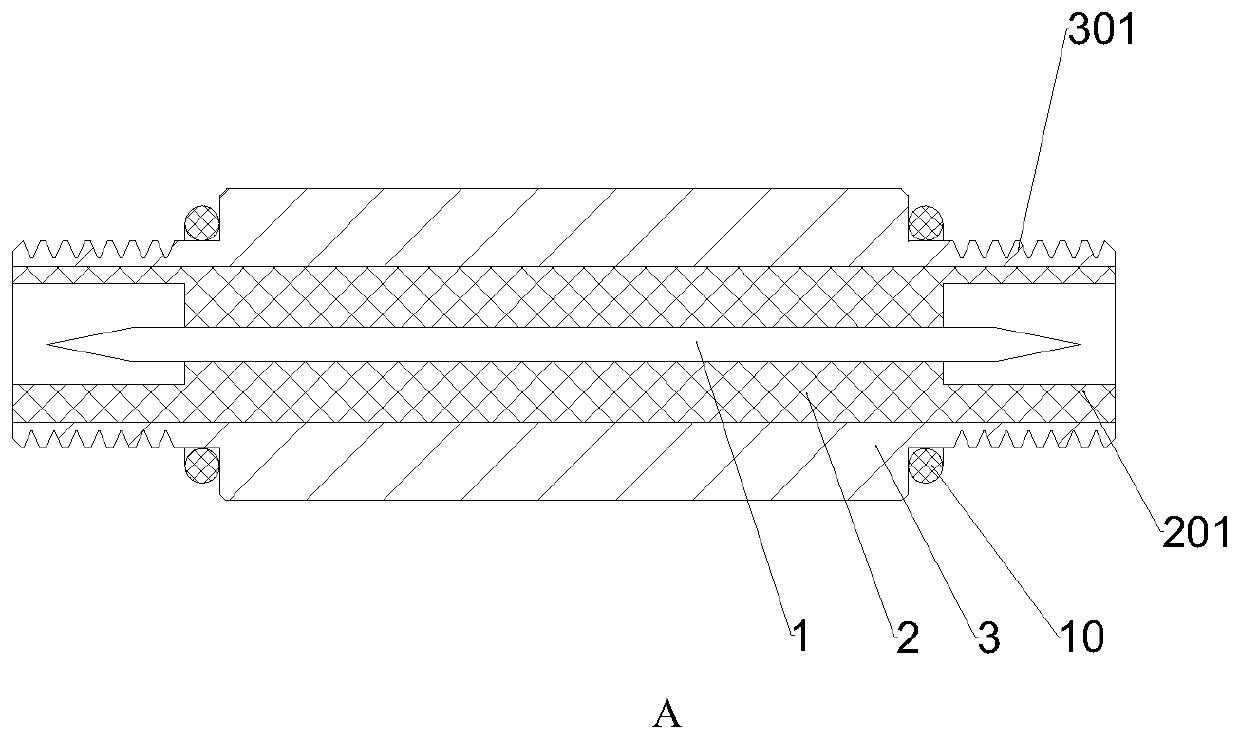

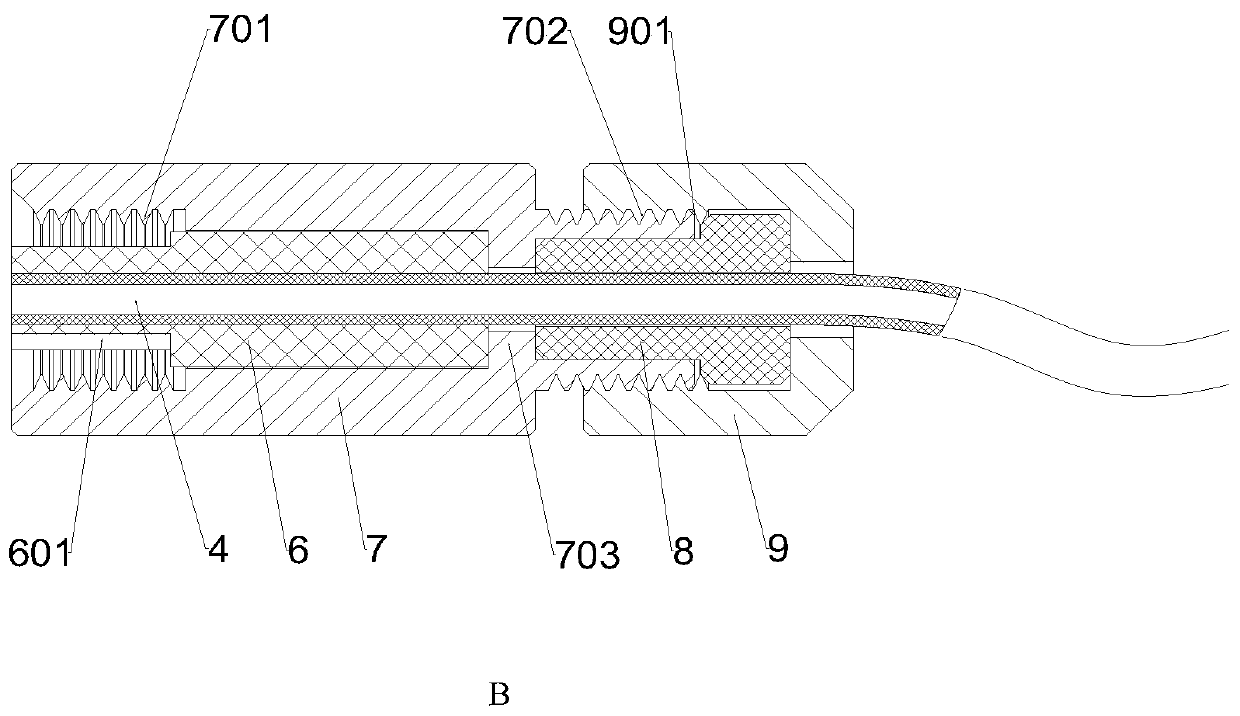

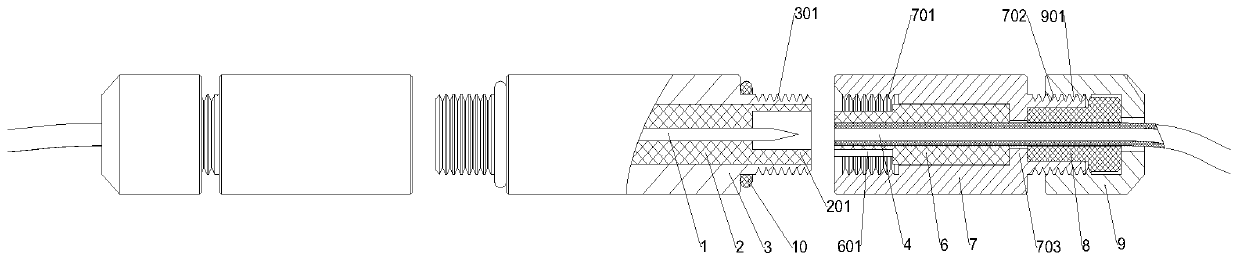

[0026] Specific embodiment 1, a front piercing type cable connection device, which includes an A component and a B component, and the A component includes a stabbing member 1, a stabbing member base 2, a first connection shell 3 and a second sealing member 10; Component B includes a second connection shell 7 , a cable positioning member 6 , a wire core 4 , a first sealing member 8 and a locking member 9 .

[0027] according to figure 1 and figure 2 Schematic diagram of the structure, component A is a cylindrical structure with a circular axial section. The piercing piece base 2 is provided with piercing piece 1 along its length direction; the inner walls of both ends of the piercing piece base 2 are provided with protrusions 201; the piercing piece 1 penetrates and is fixedly connected to the piercing piece base 2; the piercing piece The base body 2 is fixed in the first connection shell 3; the extensions at both ends of the first connection shell 3 are provided with extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com