Combined-type connecting device

A combined connector and expansion piece technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problems of inconvenient connection, size error, large volume, etc., and achieve safe and reliable performance, reduced workload, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

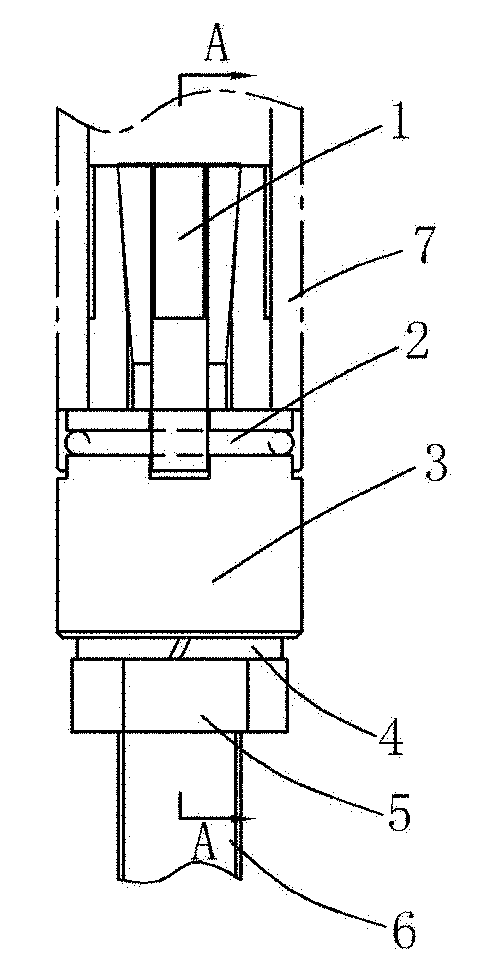

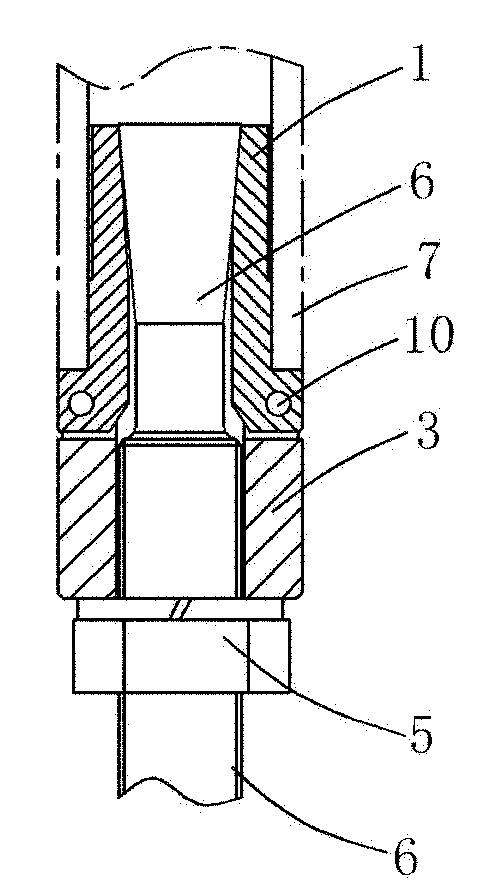

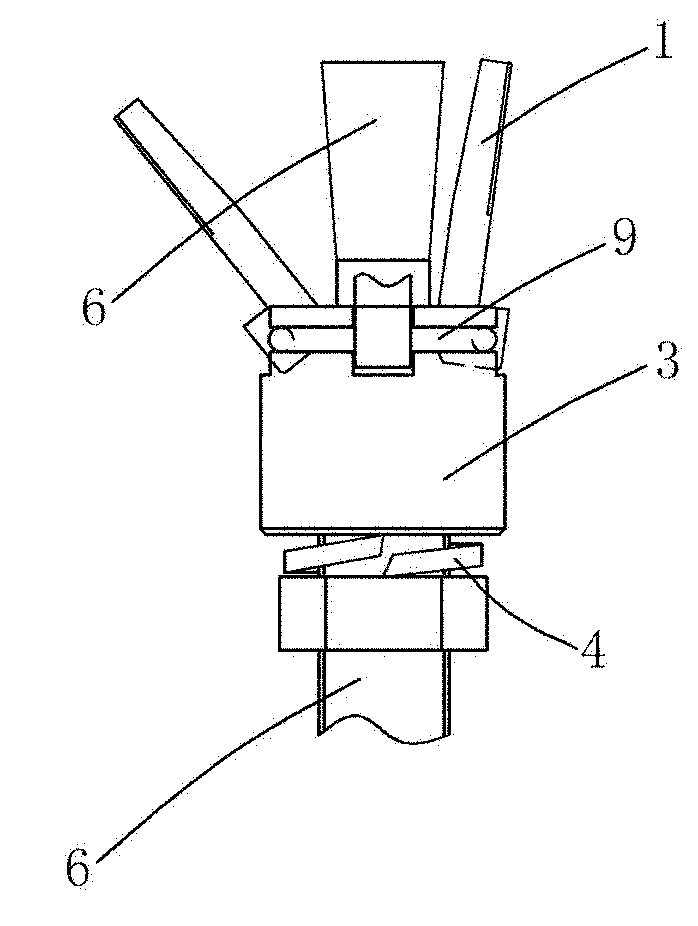

[0019] Example: Combine Figure 1-3 , the combined connector of this embodiment has:

[0020] The inner expansion taper mandrel 6 has a rounded truncated front end and an external thread on the rear end. A hexagonal nut 5 is matched and connected to this section of the external thread, and an internal expansion sheet fixing seat 3 is sleeved on the mandrel 6. One end surface of the fixed seat facing the front end of the mandrel 6 is provided with four outer grooves, and the four outer grooves are equally distributed along the circumference of the end surface of the fixed seat. Annular groove 9; four internal expansion sheets 1 are set, and the lower ends of the four internal expansion sheets are respectively inserted into the four outer grooves, and the inner surface of each internal expansion sheet and the mandrel is fitted. Conical surface; the taper of the conical surface is the same as the taper of the outer peripheral surface of the inverted truncated cone of the mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com