Pushing and blocking mechanism used during forklift discharging

A technology for a propulsion mechanism and a forklift, applied in the direction of a hoisting device, etc., can solve the problems of high labor intensity, low operation efficiency, time-consuming and labor-intensive, etc., and achieve the effects of flexible and reliable movements, improved operation efficiency, and simple overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

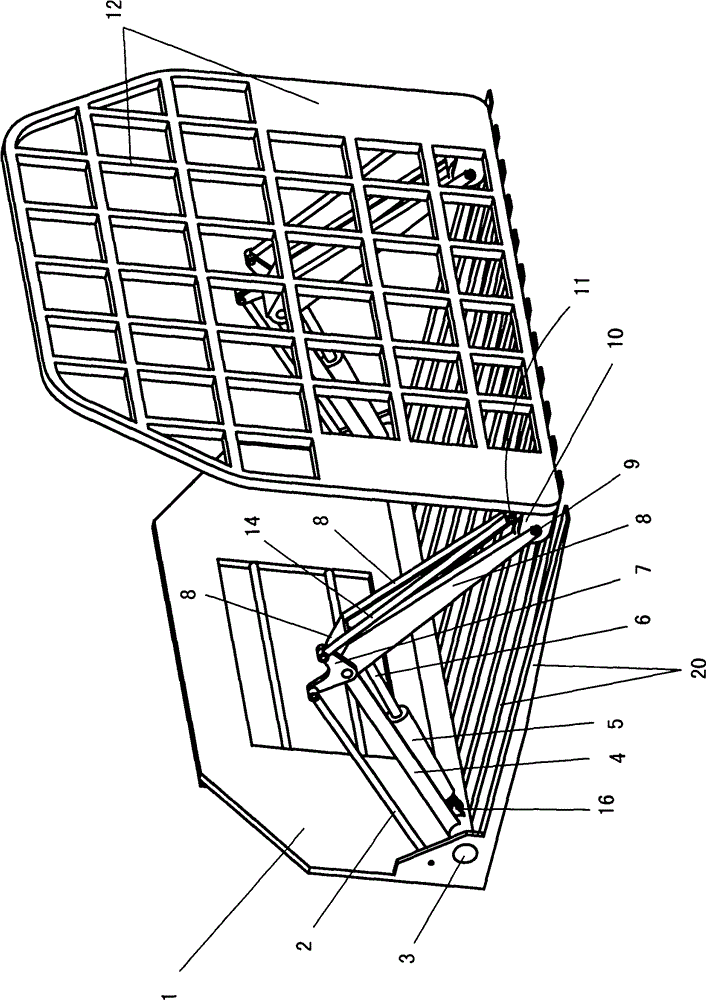

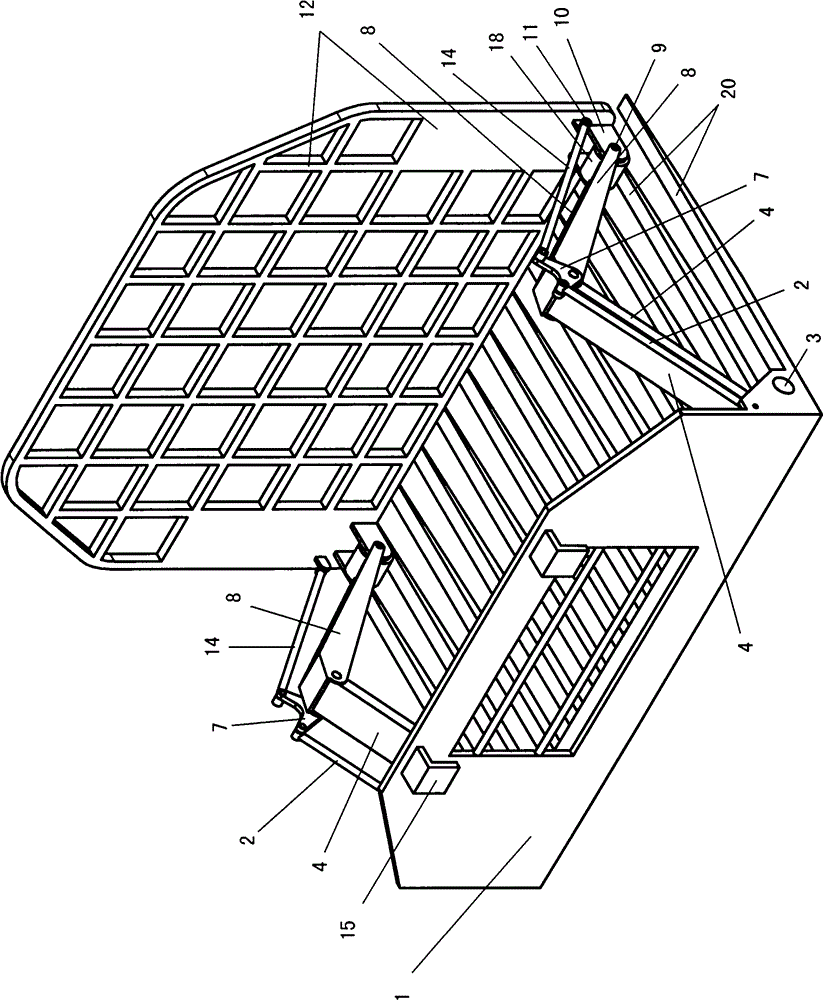

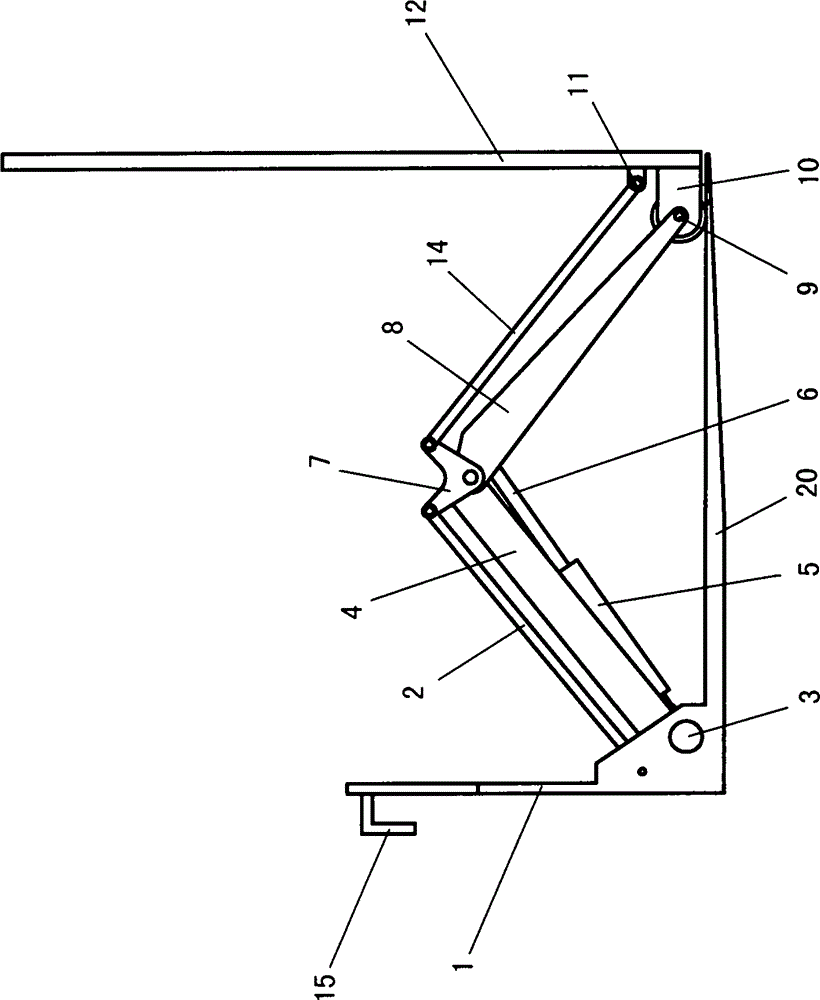

[0035] like figure 1 , 2 , shown in 3, 8: 1 is to hang the hanging plate that vertically arranges, and a plurality of mutually parallel fork tines 20 are fixedly connected on the lower side of hanging plate 1. On the fork tine 20 is seated a push block plate 12 arranged vertically. The lower bracket 10 is welded on the lower side of the push baffle plate 12, and the lower bracket 10 is equipped with a roller 18 through the lower pin shaft 9. The push baffle plate 12 is seated on the fork teeth 20 through the roller 18. There are two rollers 18, and they are respectively located on Push baffle plate 12 lower sides both sides.

[0036] A translational pushing mechanism is arranged between the push plate 12 and the hanging plate 1 , and the translational pushing mechanism includes a first connecting rod 2 , a second connecting rod 4 , a third connecting rod 8 , a fourth connecting rod 14 , and a connecting plate 7 .

[0037] The specific structure of the translational pushing...

Embodiment 2

[0049] like Figure 9 ~ Figure 17 As shown: the difference from Embodiment 1 is that a plurality of mutually parallel fork tines 20 are arranged in an arc-shaped projection on a plane perpendicular to the longitudinal direction of the fork tines 20, and the fork tines located in the middle are lower than the fork tines on both sides, forming Concave distribution structure (such as Figure 12 , Figure 13 ). The height of the support plate 31 on the base that cooperates with it changes thereupon, promptly the support plate 31 that is positioned at the center is the shortest, and the support plate 31 on both sides is the highest, forms the arc that is now toward concave, coincides with each fork tine distribution (such as Figure 15 , Figure 16 , Figure 17 ). During operation, after forking up the goods stacked on the support plate 31, the underside of the goods also forms an arc, and then when stacking, it can be guaranteed to match the arc formed on the stacked goods, e...

Embodiment 3

[0051] like Figure 18-22 Shown: different from embodiment 2 is that a plurality of mutually parallel fork tines 20 are arranged in a wave shape when projected on a plane perpendicular to the longitudinal direction of the fork tines 20, and the bottom has two troughs, and the two troughs are a crest ( like Figure 21 ). The height of the support plate 31 on the base that cooperates with it changes thereupon, and the height of the support plate 31 is wave-shaped (as in the cross-section of each support plate) Figure 22 ). During operation, after forking up the goods stacked on the support plate 31, the underside of the goods also forms an arc, and then when stacking, it can be guaranteed to match the arc formed on the stacked goods, ensuring the stability of the goods stacking , It also ensures that the space in the container is fully utilized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com