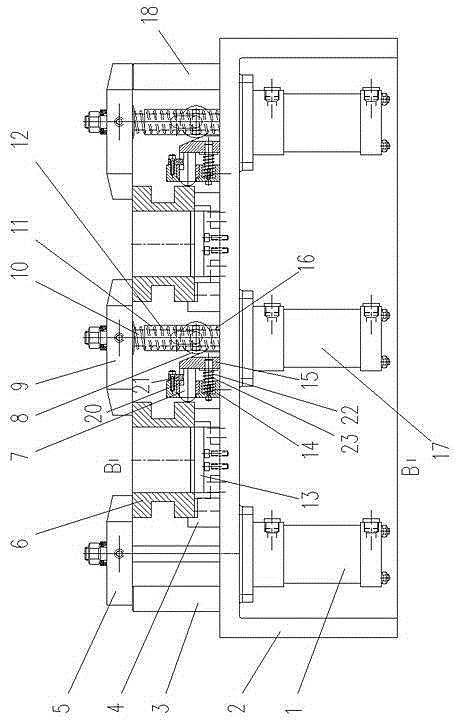

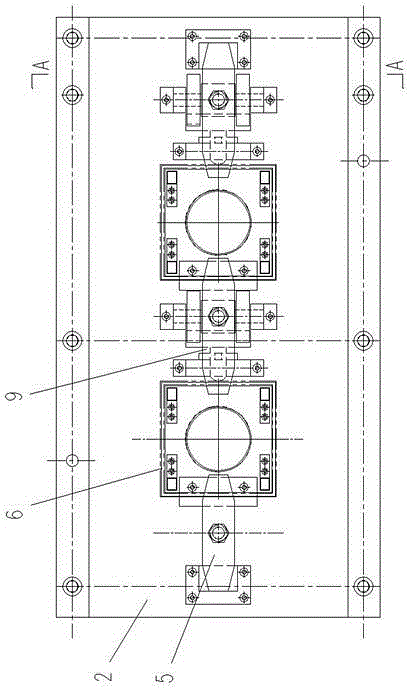

Square tool table pushing, positioning and clamping mechanism for lathe

A square tool post, positioning and clamping technology, used in positioning devices, clamping, metal processing mechanical parts, etc., can solve the problems of low workpiece machining accuracy, inability to save costs, and high cost of space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

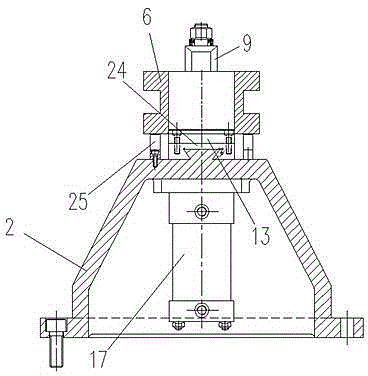

[0013] Such as figure 1 , 2 , shown in 3, 4, 5, 6: 2 is a frame, on the frame 2 vertically arranged with the side oil cylinder 1 that is positioned at both sides and the middle oil cylinder 17 that is positioned at the middle that joins with hydraulic control device. The upper end of the piston rod matched with the side oil cylinder 1 is rotatably connected with a side pressing plate 5 through a pin shaft, and the upper end of the middle piston rod 10 matched with the middle oil cylinder 17 is rotatably connected with an intermediate pressing plate 9 through a pin shaft.

[0014] On the frame 2, the two sides of the middle parts of the adjacent two piston rods are fixedly connected with the support block 25 supporting the square tool table 6 by screws, and the left side is fixedly connected with the platform 4 by screws.

[0015] A slide block 24 is provided on the frame 2, and the slide block 24 and the top of the frame 2 slide in a dovetail groove manner. The insert block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com