Double-arm manipulator for industrial production

A manipulator and double-arm technology, applied in the field of mechanical devices, can solve problems such as wasting time, and achieve the effects of convenient use, wide application range and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

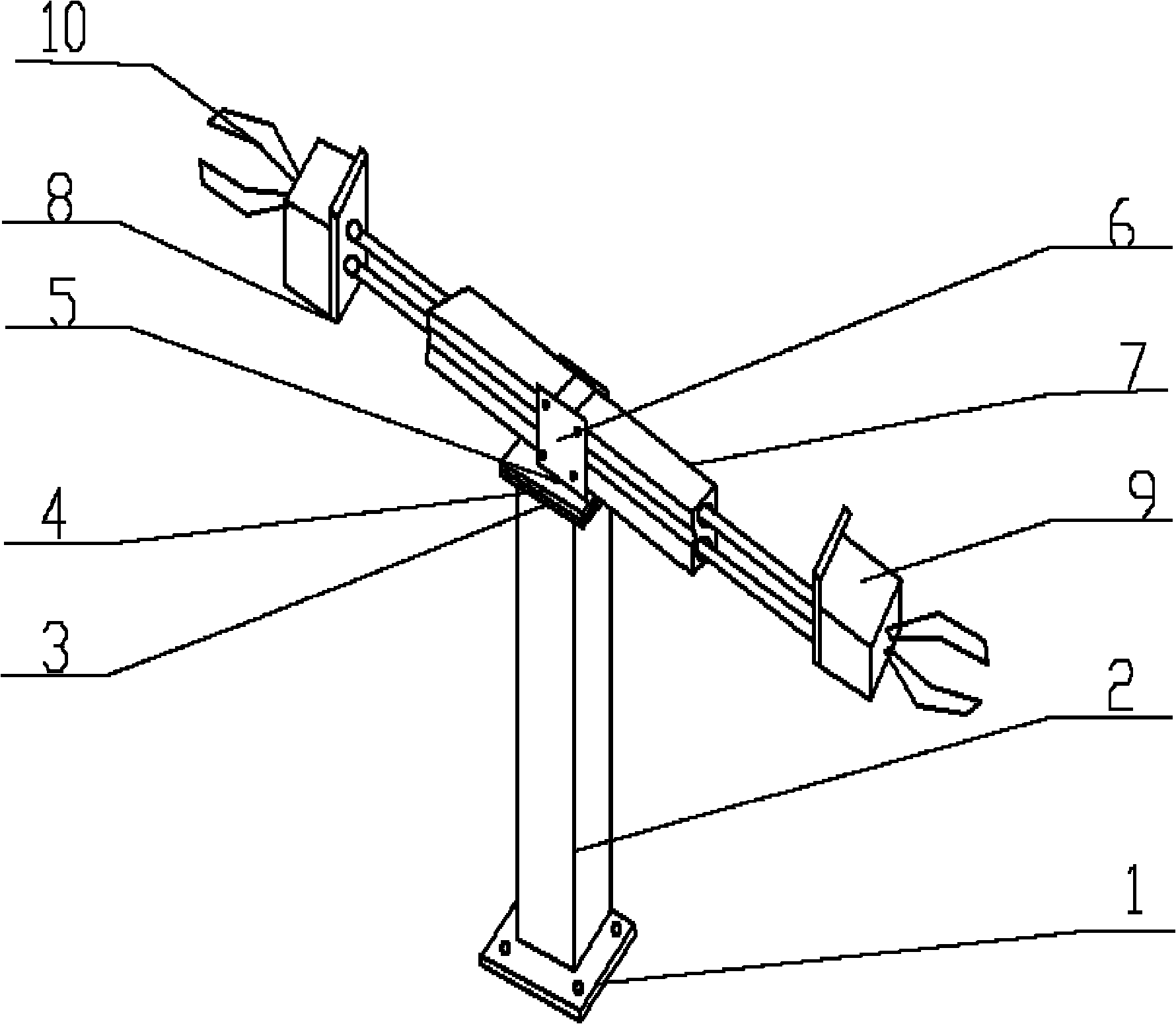

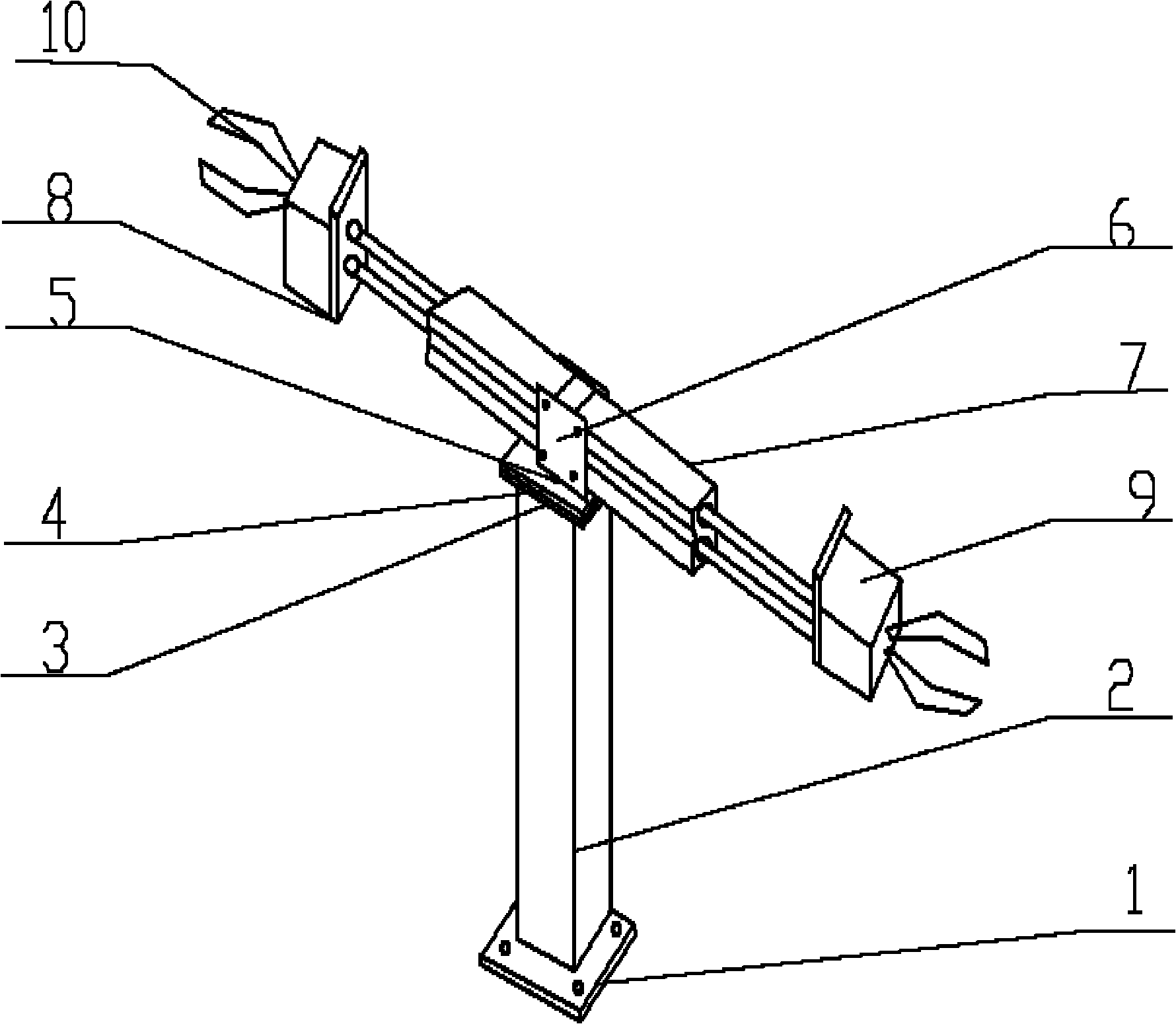

[0015] like figure 1 As shown, the present invention is installed in the working position through the bottom plate 1, and the stepping motor mandrel 5 in the column 2 passes the column interface plate 3, the motor interface plate 4, and the large curved plate 6 to control the rotation of the horizontal air cylinder 7, and the horizontal air cylinder 7 The telescopic axis installs the claw cylinder 9 through the small curved plate 8, and realizes the telescopic movement of the two mechanical arms in the horizontal plane through the telescopic axis of the two horizontal pneumatic cylinders 7. The telescopic movement of the telescopic shafts of the two claw cylinders 9 realizes the The opening and closing of two claws 10.

[0016] Although the specific implementation of the present invention has been described above in conjunction with the accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com