Heat insulating device for improving formation of hot bent glass

A technology for glass forming and heat insulation devices, which is applied in the field of heat insulation devices to improve the heat insulation devices for hot bending glass forming. It can solve the problems of poor dimensional stability of the glass spherical surface, affecting the cooling effect of the glass, and reducing the heat absorption effect. Easy to absorb heat, good heat-shielding effect, and quality-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

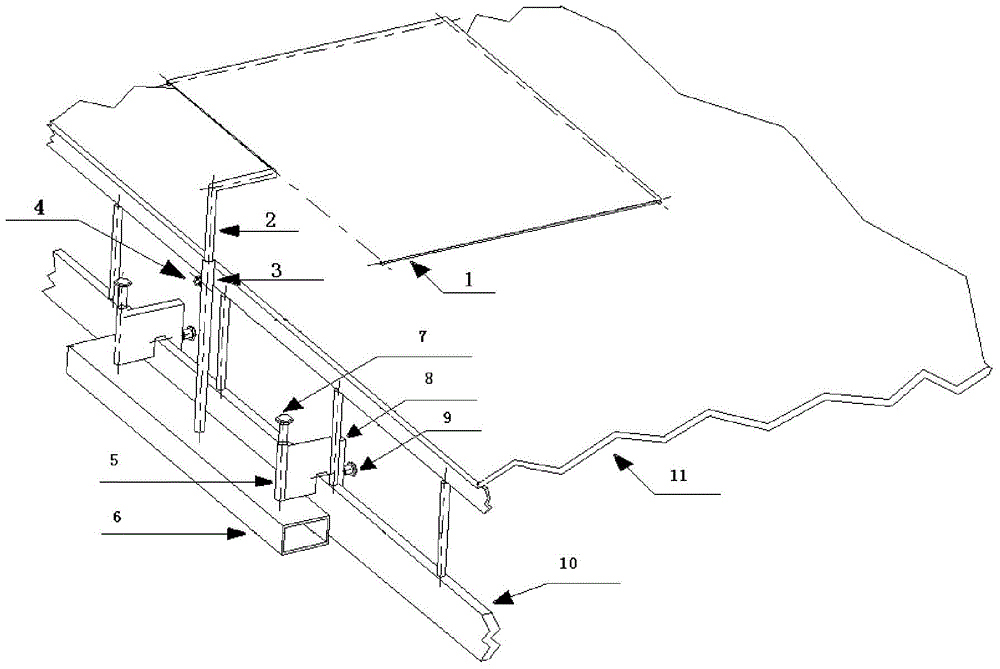

[0026] Such as figure 1 As shown, a heat insulation device for improving the forming of hot-bending glass is arranged on one side of the glass mold 10, and heat-insulates the glass workpiece 11 to be processed on the glass mold 10, and the device includes an umbrella surface heat insulation board 1. The base 6 and the support mechanism arranged on the base 6, the umbrella cover heat shield 1 can be vertically lifted and arranged on the base 6 through the support mechanism, and the base 6 is also provided with a positioning column 7 and can be slid up and down and set on the positioning The fixing buckle 8 on the column 7, in the working state, the base 6 is fixedly connected with the glass mold 10 through the fixing buckle 8.

[0027] Wherein, the support mechanism includes an adjustment sleeve 3 vertically arranged on the base 6, a first adjustment screw 4 arranged on the adjustment sleeve 3, and a support frame 2 arranged in the adjustment sleeve 3, and the support frame 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com