A kind of superfine retarded calcium aluminate cement and preparation method thereof

A technology for retarding setting calcium aluminate and calcium aluminate cement, which is applied in the field of aluminate cement for refractory materials, and achieves the effects of prolonging the demoulding time, prolonging the working time and reducing the addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

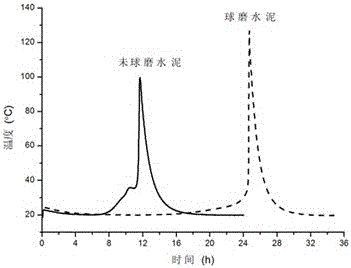

[0026] Prepare the clean slurry of unmilled calcium aluminate cement and ultrafine calcium aluminate cement after ball milling, and test its hydration exotherm curve, see figure 1 . With the reduction of cement particle size, that is, D50 decreases from 12.39 μm to 1.36 μm, the time for the cement paste to release heat at 20°C is delayed from 7h to 14h, and the time for the peak of hydration heat to appear is delayed from 11.7h to 24.7h h.

Embodiment 2

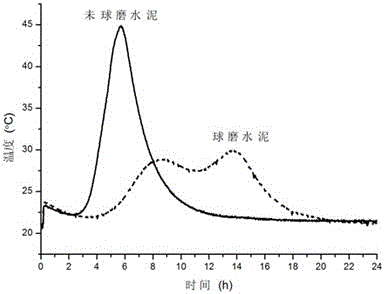

[0028] Prepare mortars of unmilled calcium aluminate cement and ultrafine calcium aluminate cement after ball milling, and test their hydration exothermic curves (see figure 2 ) and its coagulation time. With the decrease of cement particle size, that is, D50 decreases from 12.39 μm to 1.36 μm, the time for cement mortar to release heat at 20°C is delayed from 2.5h to 4h, and the time for hydration heat release peak is delayed from 5.7h to 13.8h h, the initial setting time of mortar is delayed from 3h 35min to 6h 35min, and the final setting time is delayed from 3h 55min to 7h 25min.

Embodiment 3

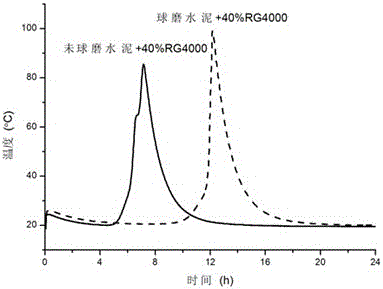

[0030] Prepare unmilled calcium aluminate cement, ultrafine calcium aluminate cement after ball milling, and 40% RG4000 Al 2 o 3 After mixing the fine powder, and test its hydration exothermic curve, see image 3. With the decrease of cement particle size, that is, D50 decreases from 12.39 μm to 1.36 μm, at 20°C, the time for cement paste to release heat is delayed from 4.8h to 8.5h, and the time for hydration heat release peak is delayed from 7.1h to 12.2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com