Constant-component crystal growth control system and method for lifting single-crystal furnace

A control system and growth control technology, which is applied in the field of crystal constant component growth control system of pulling single crystal furnace, can solve problems such as uneven crystal distribution, achieve the effect of solving axial uneven distribution and improving influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

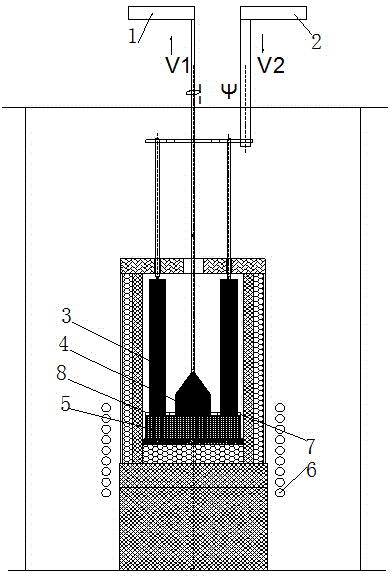

[0014] The present invention improves and optimizes the design on the basis of the original pulling single crystal furnace, and is mainly composed of two major parts: the crystal automatic growth control system and the material bar automatic replenishment control system, such as figure 1 shown.

[0015] Crystal automatic growth control system

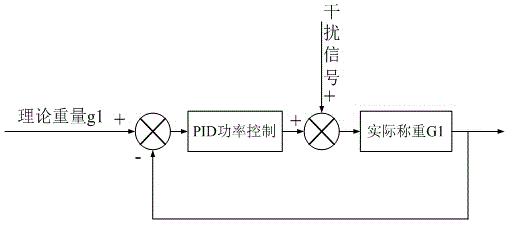

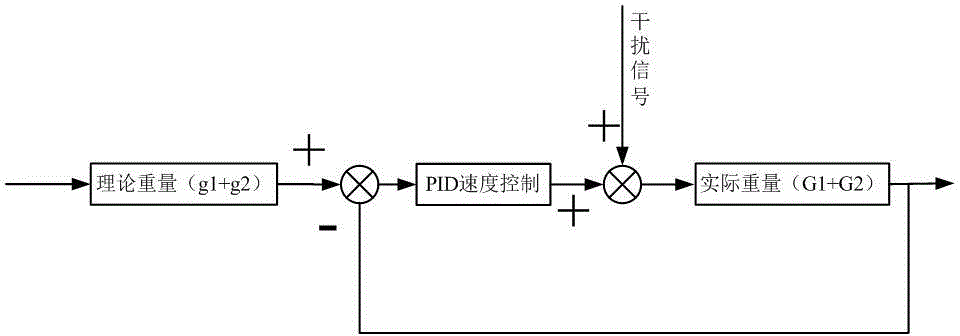

[0016] The crystal automatic growth control system consists of a scale I1, a lifting system, a rotating system, and an induction heating module 6 (i.e. figure 1 Induction coil) and other components. The scale I1, the lifting system, the rotating system and the induction heating module 6 are respectively connected with the control module. Scale Ⅰ1 measures the weight G of the growing crystal 4 in real time 1 ;The lifting system generates a certain lifting speed v through the stepping motor 1 The crystal grows continuously; the rotation system generates a certain rotation speed ω through the torque motor to realize the stability of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com