Labor-saving brick clamp

A technology of bricks and straight teeth, which is applied in the field of labor-saving bricks and can solve problems such as laborious and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

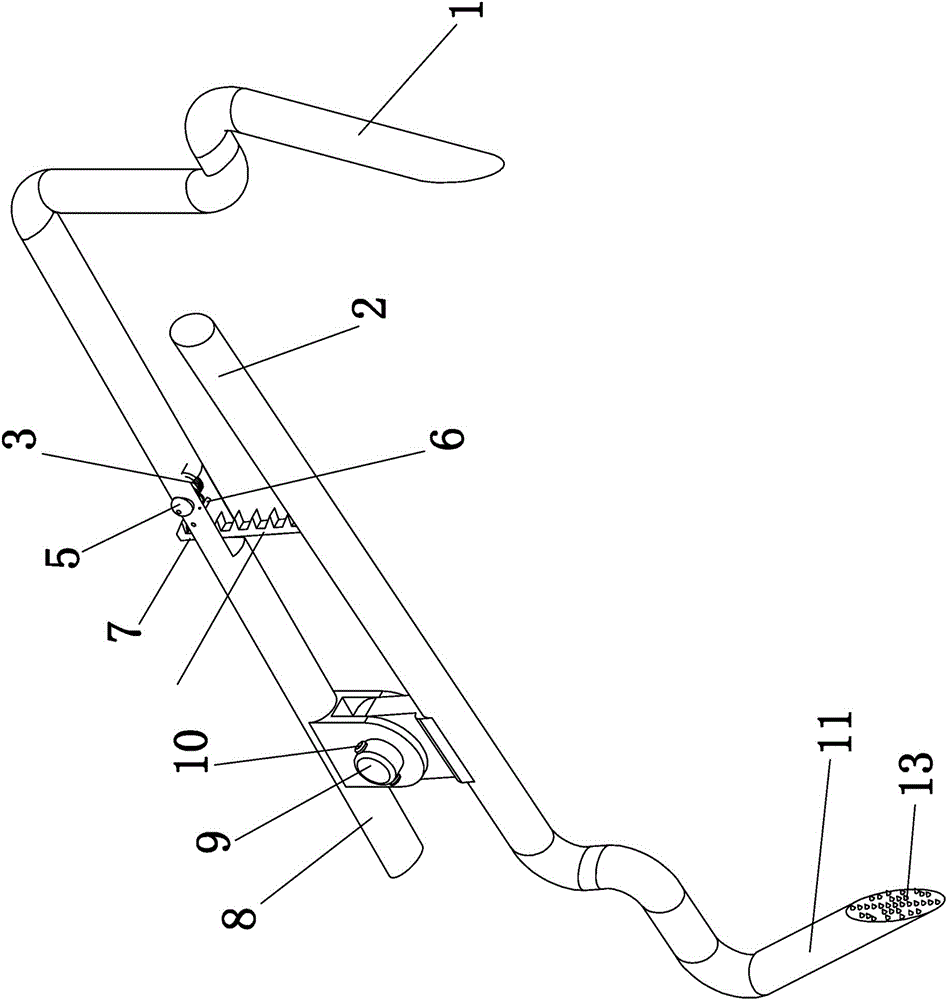

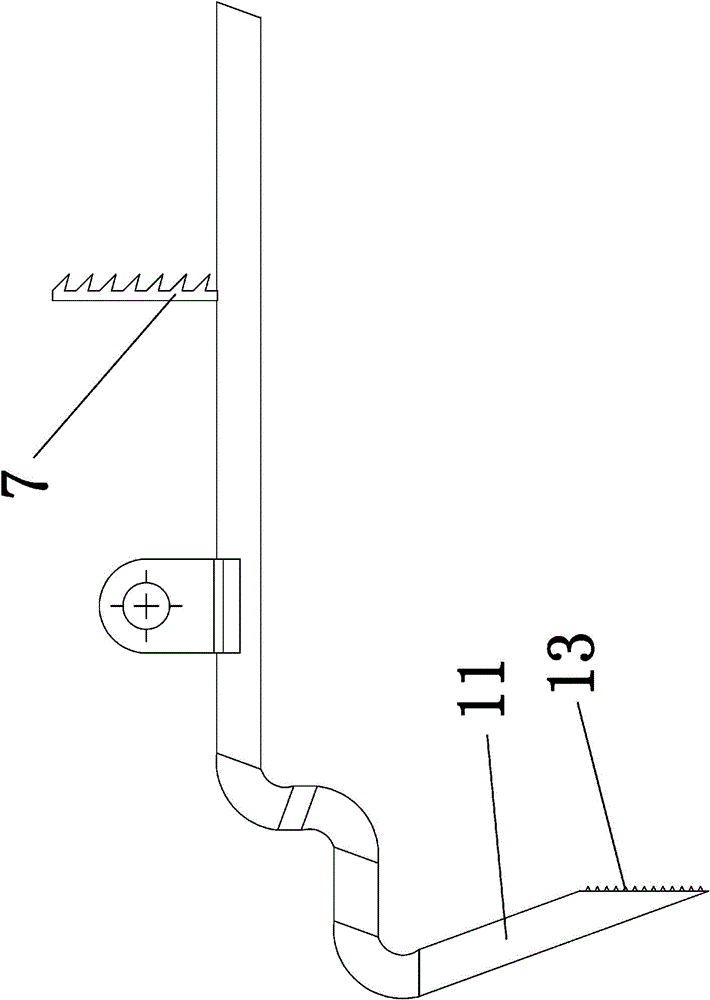

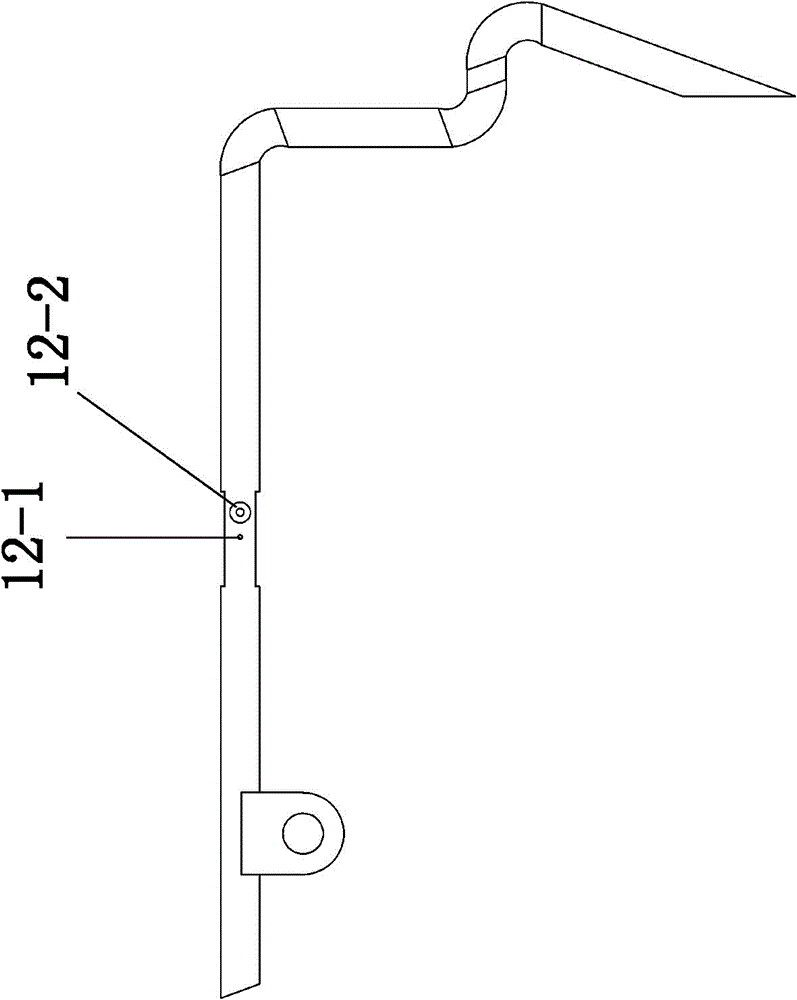

[0019] Such as Figure 1-Figure 6 As shown, a labor-saving brick card includes a left-hand piece composed of a left handle 2 and a left gripper 11. It is characterized in that: the left-hand piece and the right-hand piece are pinned through a latch 9, and the left-hand piece is provided with vertical straight teeth 7. The right hand member is provided with a groove body 12 matching with the vertical straight teeth 7, and the groove body 12 is respectively provided with a gear rod installation hole 12-1, a work piece installation hole 12-2 and The spring fixing hole 12-3, the work piece 5 is composed of the rotating block 5-1 and the insertion rod 4 inserted into the rotating block 5-1, and the rotating rod 5-1-1 of the rotating block 5-1 is provided with a spring mounting hole 5- 1-2, the gear rod 6 is inserted into the gear rod mounting hole 12-1 and matched with the rotary rod 5-1-1, the rod head of the rotary rod 5-1-1 is matched with the vertical straight teeth 7, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com