White smoke and power reduction high-efficiency counter flow cooling tower and control method thereof

A control method and high-efficiency technology, applied in the direction of water shower coolers, direct contact heat exchangers, heat exchange equipment, etc., can solve the problems of increasing power consumption of blowers, wasting power consumption of high-temperature fluid pumps, etc., and achieve low power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0156] A preferred embodiment of the high-efficiency counterflow cooling tower and its control method for reducing white smoke and power according to the present invention will be described in detail below with reference to the accompanying drawings.

[0157] First, a detailed description of the structure and function of the conventional technology that can confuse the gist of the present invention is omitted.

[0158] In addition, in each of the embodiments, the same reference numerals are used for components having the same structure, and only a representative one embodiment will be described, and in the remaining embodiments, only the structures different from the above-mentioned one embodiment will be described.

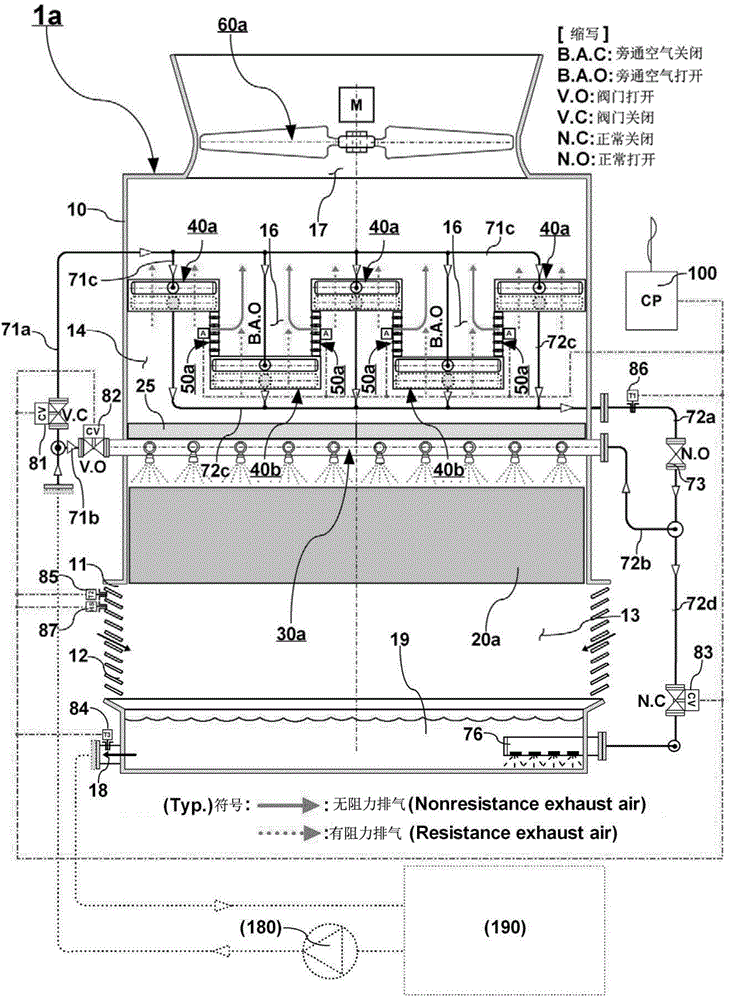

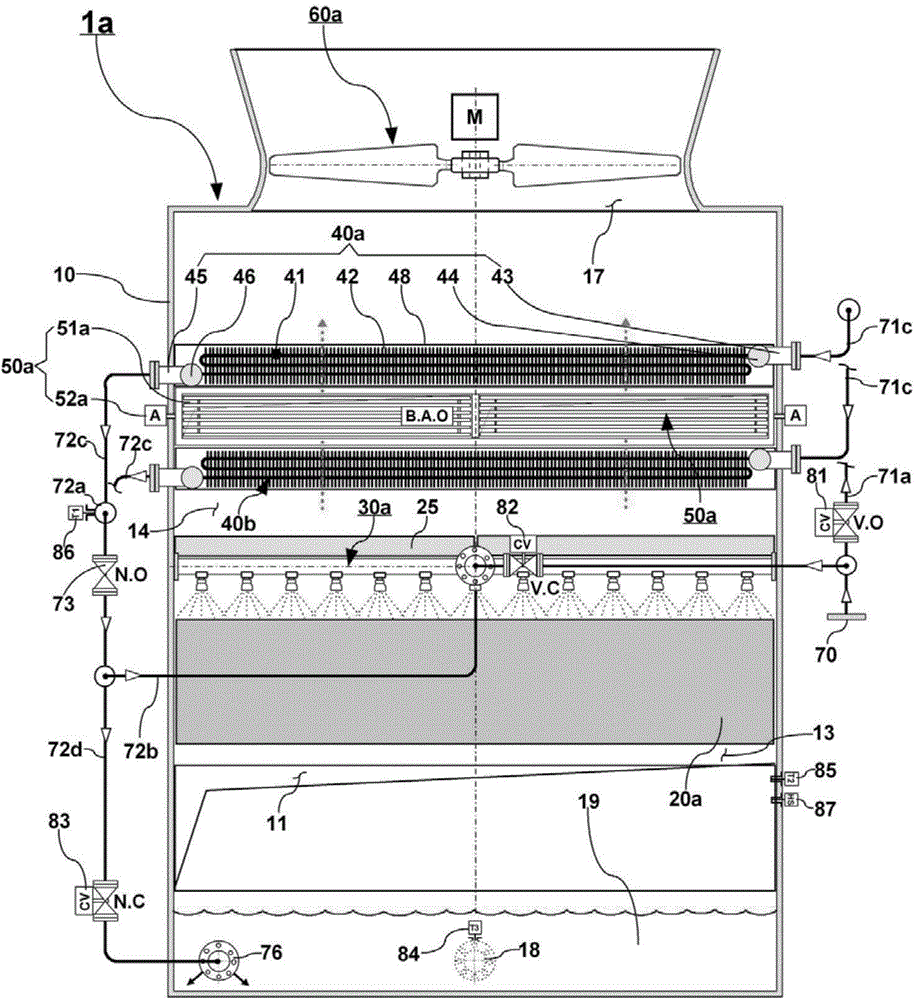

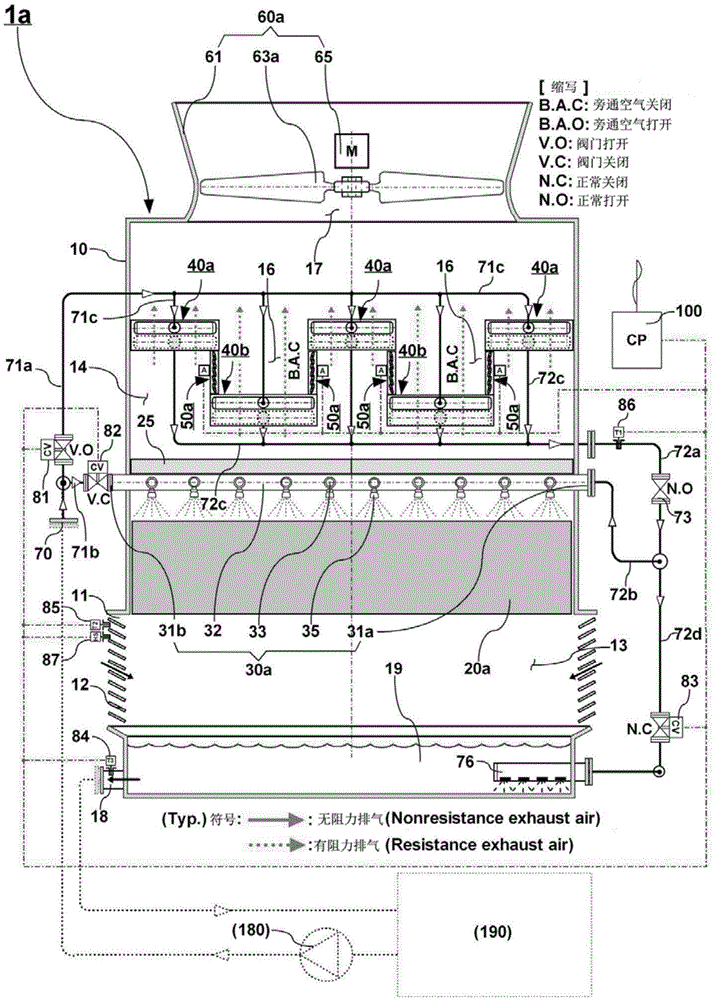

[0159] figure 1 It is a schematic side sectional view showing a high-efficiency counterflow cooling tower and a wet cooling operation structure for reducing white smoke and power according to the first embodiment of the present invention, figure 2 is true fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com