A self-supporting outdoor aerial cable

A self-supporting, outdoor technology, applied in light guides, optics, instruments, etc., can solve problems such as shortening the service life of optical cables, damage to the sheath of optical cables, and metal supports that are susceptible to moisture corrosion, so as to reduce maintenance or replacement costs The effect of frequency, prolonging service life and ensuring stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

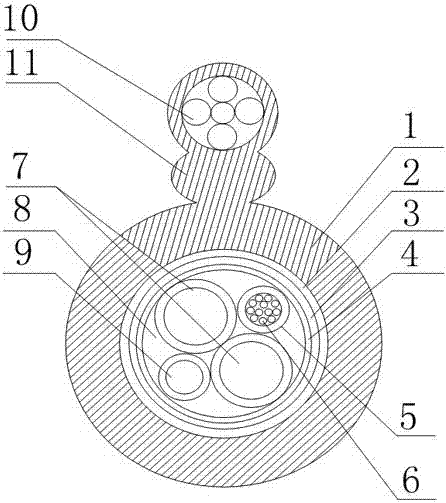

[0020] Such as figure 1 As shown, this embodiment includes a PE sheath 1 and a steel-plastic composite strip 2 arranged on the inner wall of the PE sheath 1, and two tangent and simultaneously connected steel-plastic composite strips 2 are arranged on the diameter of the steel-plastic composite strip 2. The insulated copper wire 7 whose inner wall is tangent also includes a loose tube 5 and a sheathed steel wire 9 arranged on both sides of the two copper wires 7. The loose tube 5 is filled with optical fibers 6, and in the The gap inside the steel-plastic composite belt 2 is filled with water-blocking cable paste 8, and the outer wall of the PE sheath 1 is connected with a sheathed steel rope 10 through a sling 11, and the cross-section of the sling 11 is oval. In view of the prior art, the laying of optical cables in rural areas is easily affected by complex weather changes, resulting in damage to the sheath of the optical cable, and the metal support in the sheath is easily ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com