Chip cleaning method and device

A chip cleaning and chip technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as static electricity generated by chips, and achieve the effects of easy release and reduced water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

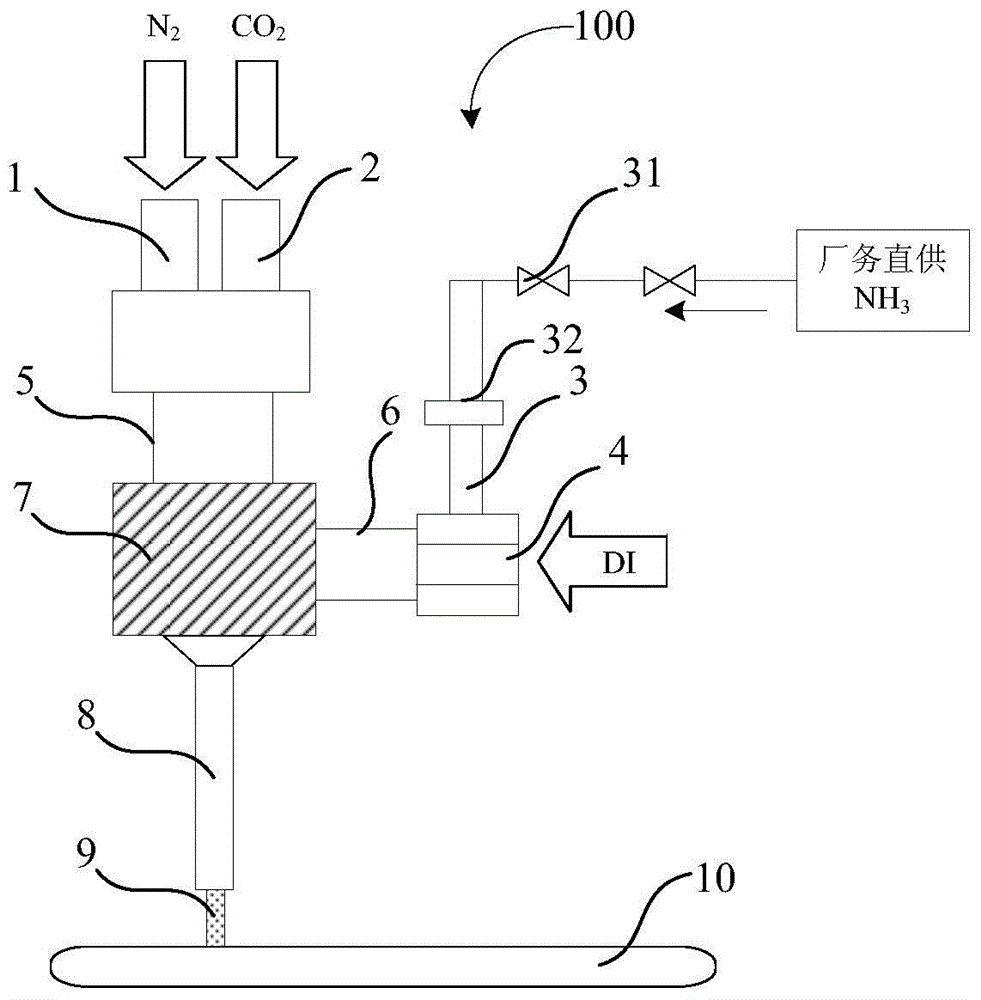

[0039] The invention provides a chip cleaning method. The chip cleaning method at least includes an atomization and spraying step. In the atomization and spraying step, a cleaning agent is sprayed on the chip surface to be cleaned by an atomization and spraying device; the cleaning agent includes A gas-liquid mixture of nitrogen, ammonia, carbon dioxide and deionized water (DI); the water resistance of the mixed liquid in the gas-liquid mixture is 50-80KΩ·CM. The atomization cleaning device such as figure 2 shown.

[0040] Specifically, the chip includes a semiconductor substrate and a device structure and a metal interconnection structure fabricated on the semiconductor substrate.

[0041] When using the chip cleaning method provided by the present invention, the cleaning agent comprising nitrogen, ammonia, carbon dioxide and deionized water is first passed into the atomization spray cleaning device 100 through each corresponding inlet, and then the cleaning agent is passed...

Embodiment 2

[0058] The present invention also provides a chip cleaning device, which is used in the chip cleaning method of Embodiment 1, such as figure 2 As shown, the chip cleaning device at least includes an atomization spray cleaning device 100, and the atomization spray cleaning device 100 includes a nitrogen gas introduction part 1, an ammonia gas introduction part 3, a carbon dioxide introduction part 2 and a deionized water introduction part 4, the The outlet of the nitrogen gas introduction part 1, the outlet 3 of the ammonia gas introduction part, the outlet of the carbon dioxide introduction part 2 and the outlet of the deionized water introduction part 4 communicate with a connecting piece 7, and the connecting piece 7 is also provided with a nozzle 8.

[0059] Further, the nitrogen introduction part 1 and the carbon dioxide introduction part 3 communicate with the connecting piece 7 through the first conduit 5, and the nitrogen and carbon dioxide introduced into the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com