Brake device of track conveying equipment

A brake device and rail transportation technology, which is applied in the direction of transportation and packaging, brakes interacting with brake components and rails, railway braking systems, etc., can solve the problems of inconvenient installation of disc spring replacement, worn brake blocks, and installation accuracy Advanced problems, to achieve the effect of good braking effect, fast braking speed and large opening angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

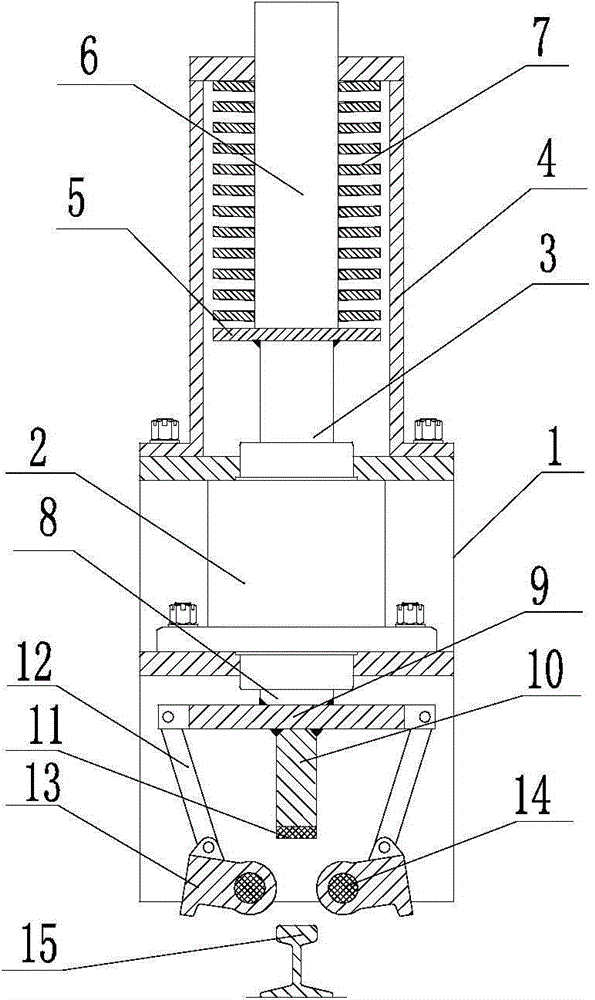

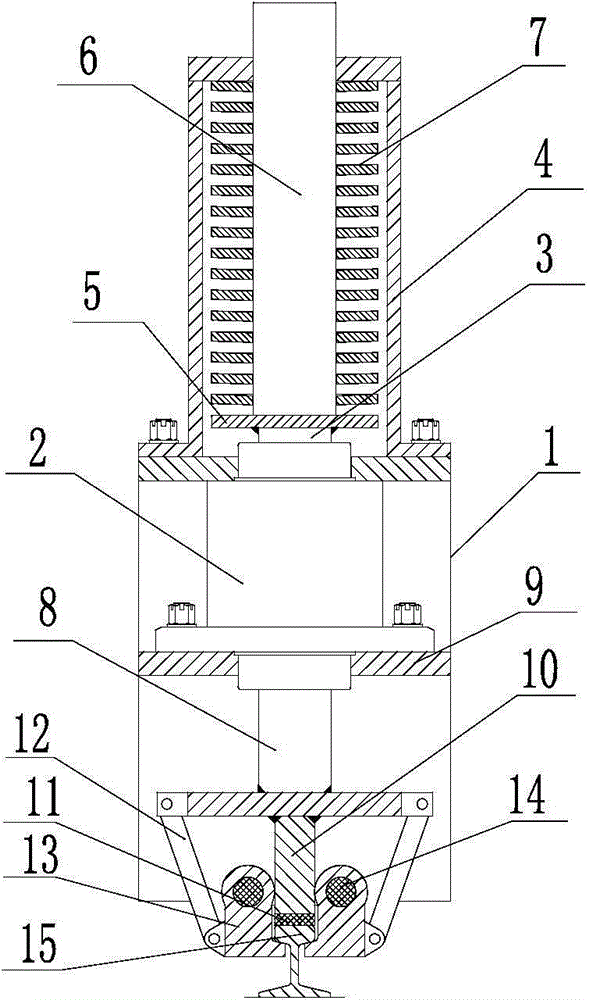

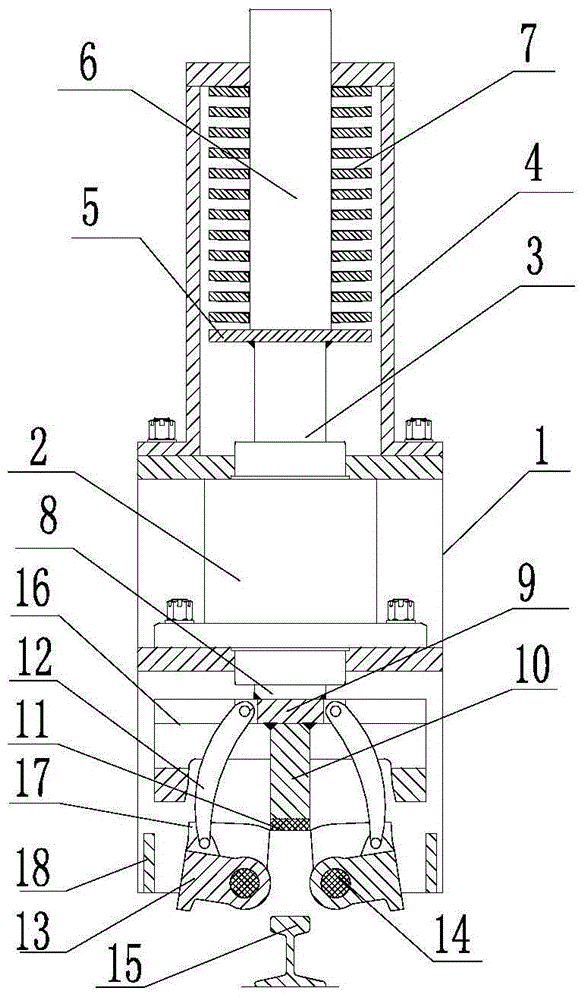

[0018] Such as figure 1 , figure 2 As shown, a brake device for rail transportation equipment is equipped with an oil cylinder 2 on the bracket 1, a lower push rod 8 and an upper push rod 3 are respectively installed on both sides of the oil cylinder 2, and a guide rod frame is installed on the upper side of the oil cylinder 2. 4. A spring push plate 5 is installed on the upper push rod 3, and a spring 7 is installed between the spring push plate 5 and the guide rod frame 4. The spring 7 is a disc spring; 9 The lower side is equipped with a brake lever 10, and a connecting rod 12 is installed on the top of the pressure plate 9. The other end of the connecting rod 12 is connected to the rotating brake claw 13, and the rotating brake claw 13 passes through the rotation axis of the rotating brake claw. 14 is contained on the support 1.

[0019] Such as image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a brake device for rail transportation eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com