Intelligent hanging and conveying device rail system

A technology for conveying equipment and rails, applied in the field of rail systems, can solve the problems of non-perpendicular and non-parallel upper and lower rails, inability to guarantee the accuracy of upper and lower connections, and poor integrity of rail connections, and achieve improvements in tightness, firmness, convenience, and convenience. Lightweight and convenient installation, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

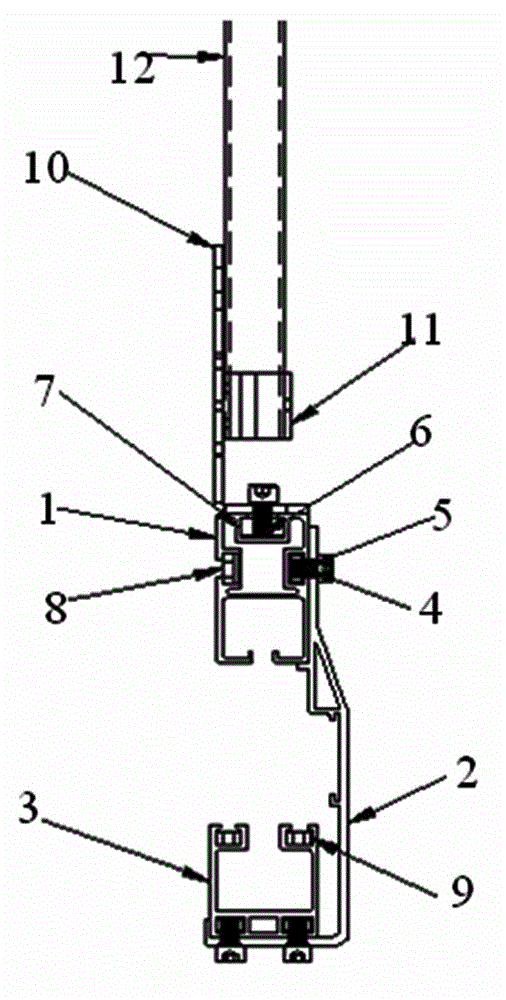

[0009] Such as figure 1 As shown, the track system of the intelligent suspension conveying equipment of the present invention comprises a suspension conveying power rail 1, an upper and lower rail side connecting plate 2, a suspension conveying storage rail 3, a square nut 4, a first cylinder head hexagon socket screw 5, and a second cylinder head inner Hexagonal screw 6, main connecting strip of the suspension transmission power track 7, side connection strip of the suspension transmission power track 8, connection adjustment plate fastener 10, boom connection fastener 11, round pipe suspension rod 12, one of the upper and lower rail side connection plates 2 The upper part of the convex groove is buckled into the side groove of the suspension transmission power track 1, and the suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com